Urethral catheterization device for nursing

A technology of urine device and catheter, which is applied in the medical field, can solve the problems of inconvenient fixation, inability to fold, and aggravation, and achieve the effects of convenient sampling, convenient drainage, and convenient hanging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

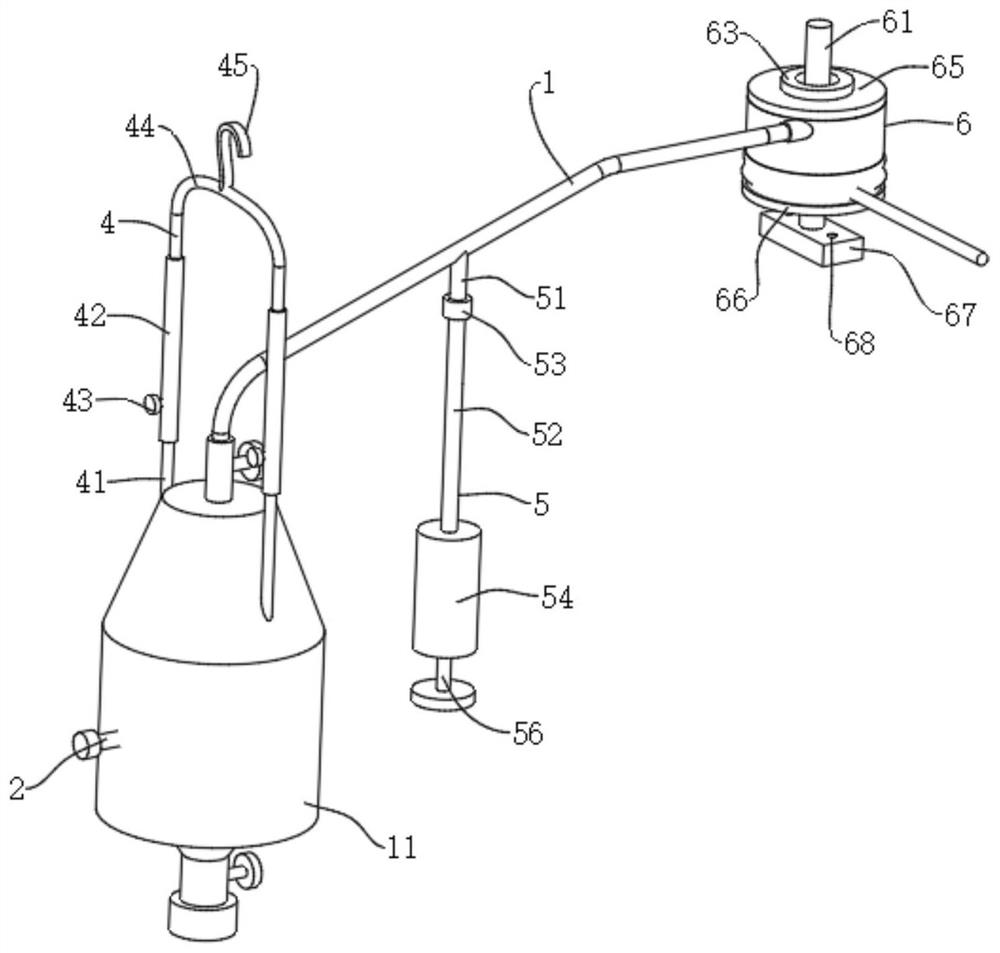

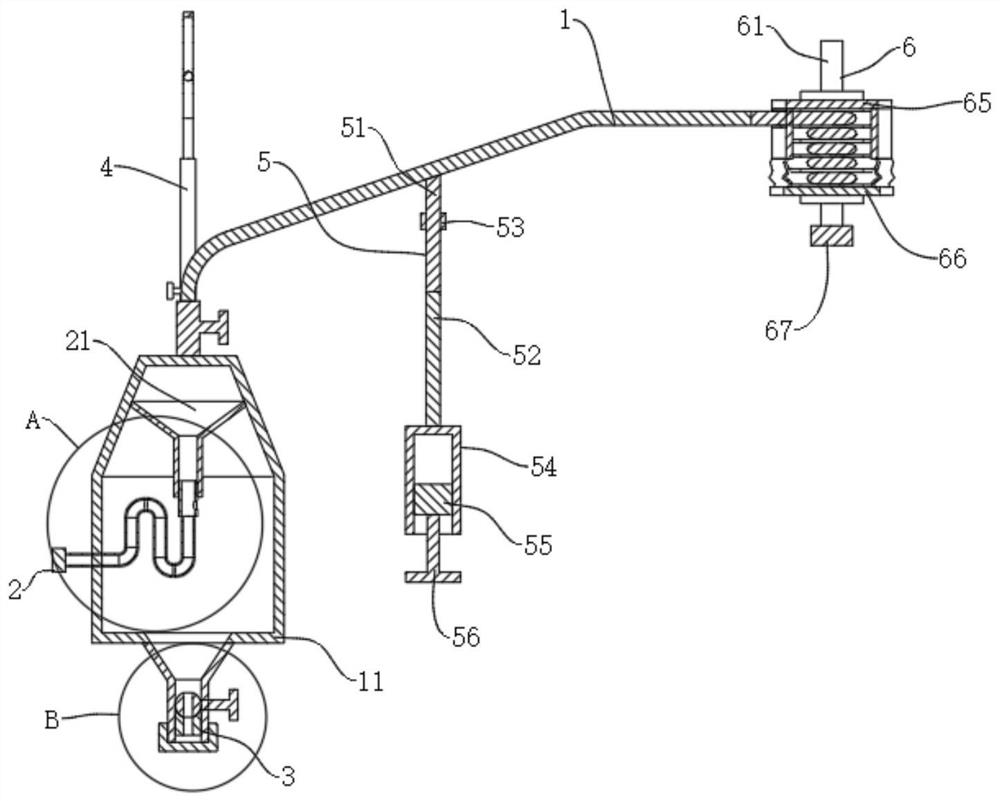

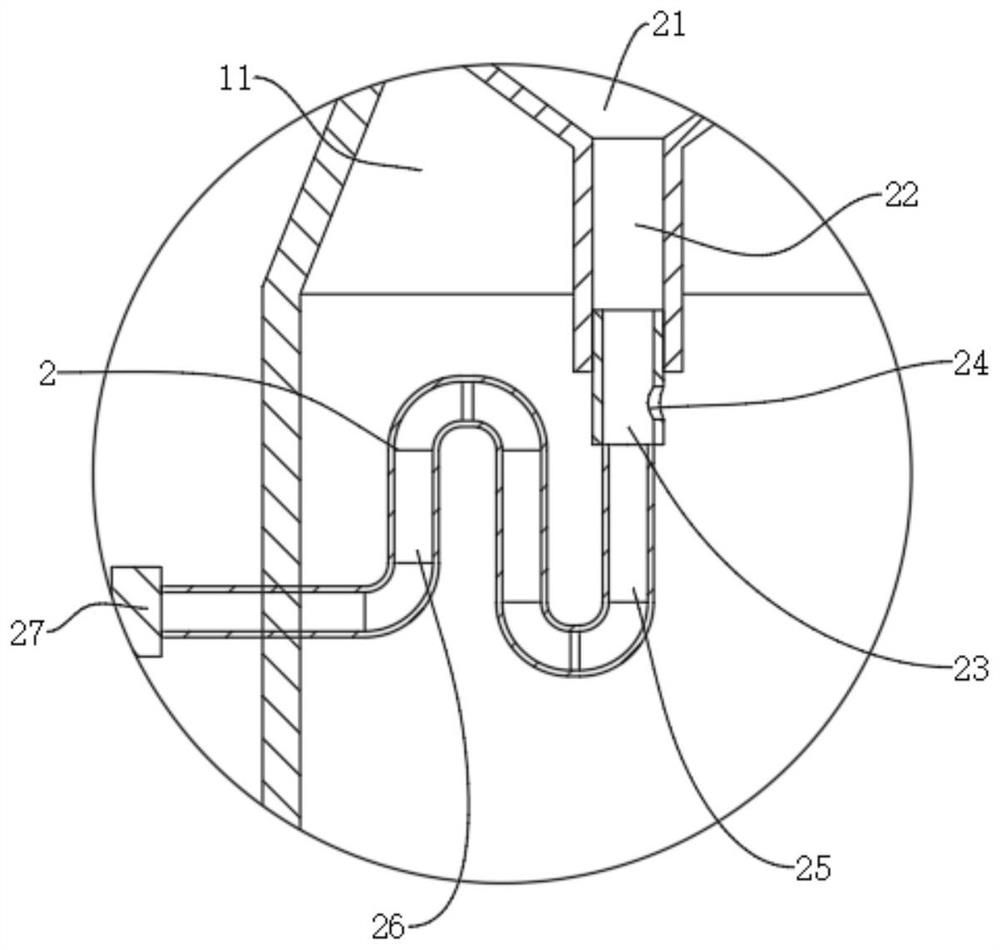

[0046] refer to figure 1 and figure 2 , nursing catheterization device, mainly includes the following parts:

[0047] Urinary catheter 1 for inserting into the patient's urethra, the urinary catheter 1 is used for urine diversion; connected to the urine bag 11 fixed at the end of the urinary catheter 1, and the urine bag 11 is used to receive urine; set on the urine bag 11 The sampling auxiliary structure 2 for convenient direct sampling of urine can be conveniently directly sampled from the urine bag 11 by using the sampling auxiliary structure 2; It can control the discharge of urine from the urine bag 11; the hook structure 4 for adjusting the height of the urine bag 11 can be used to assist the hooking and fixing of the urine bag 11; it is used when the urine tube 1 is blocked The control structure 5 for negative pressure pumping can achieve a good effect of controlling the blockage of urine in the urinary tube 1 by using the control structure 5; The gathering structur...

Embodiment 2

[0058] The difference from Example 1 is: the surface of the urine bag 11 is coated with an antifouling coating, wherein the preparation process of the antifouling coating is as follows:

[0059] S1. Take the following ingredients by weight: 40 parts of methyl trimethoxy silicon epoxy, 40 parts of polyurethane resin, 45 parts of acrylate, 8 parts of polydimethylsiloxane, 15 parts of polycarbonate, 45 parts of refined naphthalene, 10 parts of acrylamide, 5 parts of methacrylate, 14 parts of polyethylene glycol, 10 parts of stannous octoate, 10 parts of dibutyltin dilaurate;

[0060] S2. Preparation of an intermediate coating body: adding methyltrimethoxysilane epoxy, polyurethane resin, acrylate, polydimethylsiloxane, and polycarbonate into a reaction kettle at 95° C. for 30 minutes to obtain an intermediate coating body;

[0061] S3, preparation of paint: pour the intermediate paint body into the mixer, add refined naphthalene, acrylamide, methacrylate, polyethylene glycol, sta...

Embodiment 3

[0064] The difference from Example 2 is the preparation of antifouling coating, wherein the preparation process of antifouling coating is as follows:

[0065] S1. Take the following ingredients by weight: 45 parts of methyl trimethoxy silicon epoxy, 40 parts of polyurethane resin, 45 parts of acrylate, 12 parts of polydimethylsiloxane, 15 parts of polycarbonate, 45 parts of refined naphthalene, 5 parts of acrylamide, 5 parts of methacrylate, 14 parts of polyethylene glycol, 10 parts of stannous octoate, 10 parts of dibutyltin dilaurate;

[0066] S2. Prepare an intermediate coating body: add methyltrimethoxysilane epoxy, polyurethane resin, acrylate, polydimethylsiloxane, and polycarbonate into a reaction kettle at 97° C. for 30 minutes to obtain an intermediate coating body;

[0067] S3, preparation of paint: pour the intermediate paint body into the mixer, add refined naphthalene, acrylamide, methacrylate, polyethylene glycol, stannous octoate, dibutyltin dilaurate and stir t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com