Auxiliary device for graphene heat dissipation film die cutting production

A technology of auxiliary device and heat dissipation film, applied in metal processing and other directions, can solve the problems of graphite powder falling, signal transmission influence, scattered on equipment, etc., to reduce waste, reduce production cost, and avoid influence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

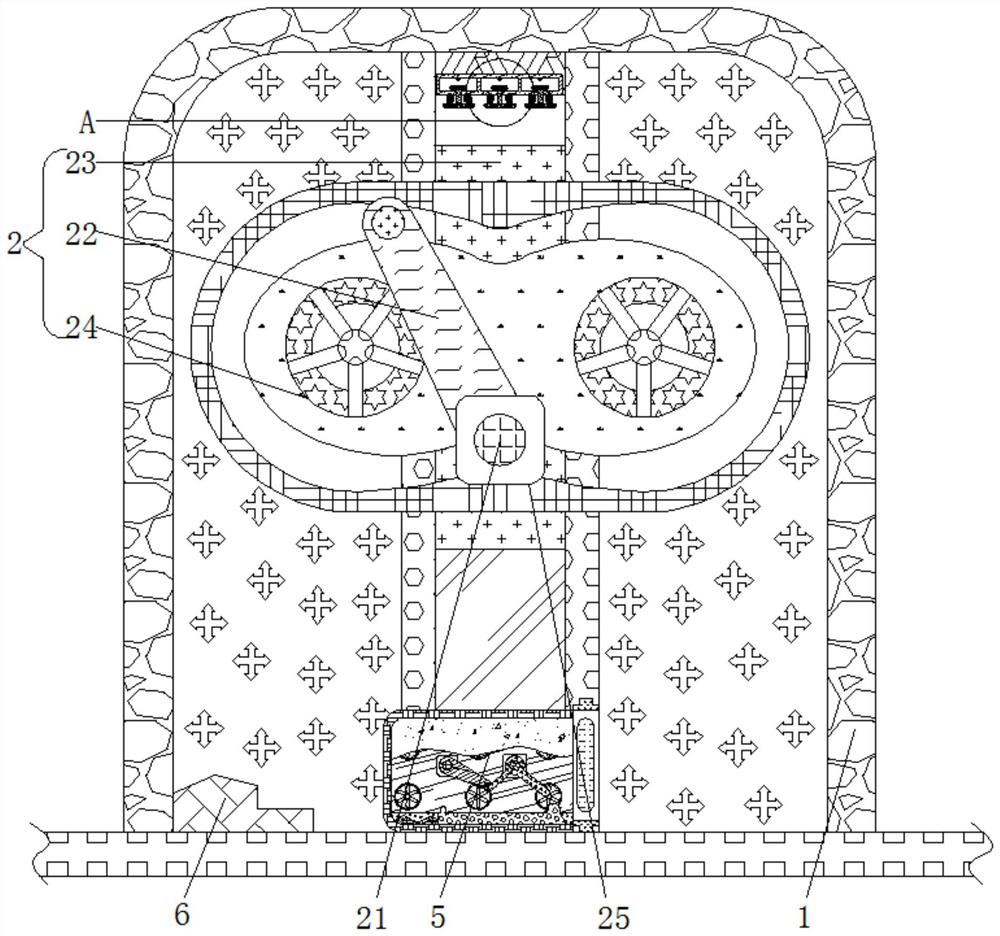

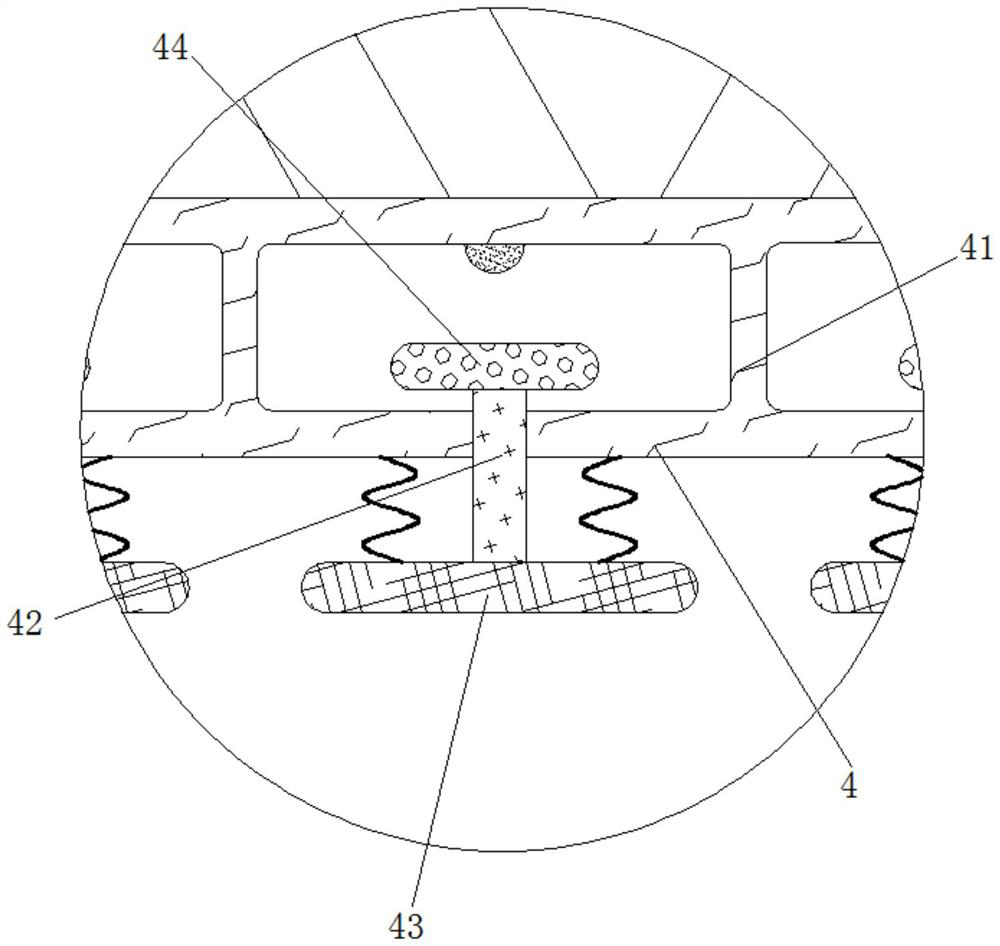

[0029] see Figure 1-2 , an auxiliary device for die-cutting production of graphene heat dissipation film, comprising a support frame 1, the inner side of the support frame 1 is movably connected with a translation mechanism 2, the outside of the translation mechanism 2 is movably connected with a cleaning mechanism 3, and the inner side of the support frame 1 A detection assembly 4 is movably connected, and the detection assembly 4 includes a housing one 41, a connecting rod 42, a baffle plate 43, and a contact plate 44. The housing one 41 is fixedly connected to the inner side of the support frame 1, and the connecting rod 42 is movably connected to the housing one. 41, the baffle 43 is fixedly connected to one end of the connecting rod 42, the contact plate 44 is fixedly connected to the other end of the connecting rod 42, the outside of the baffle 43 is fixedly connected to a spring, and the end of the spring away from the baffle 43 is fixedly connected to the shell The in...

Embodiment 2

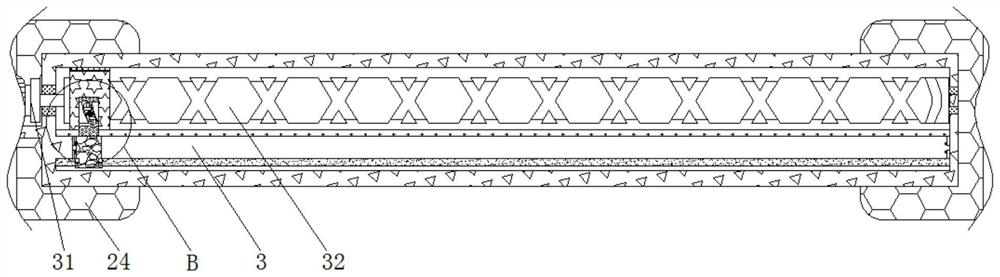

[0032] see Figure 1-5 , an auxiliary device for die-cutting production of graphene heat dissipation film, comprising a support frame 1, the inner side of the support frame 1 is movably connected with a translation mechanism 2, and the translation mechanism 2 includes a rotating shaft 21, a rotating rod 22, a sliding rod 23, a movable Frame 24, motor one 25, rotating shaft one 21 are movably connected on the inside of support frame 1, and rotating rod 22 is fixedly connected on the outside of rotating shaft one 21, slide bar 23 is slidingly connected on the inside of support frame 1, and movable frame 24 is fixedly connected on slide The outside of bar 23, motor one 25 is fixedly connected to the inboard of support frame 1; The external movement of translation mechanism 2 is connected with cleaning mechanism 3, and cleaning mechanism 3 comprises motor two 31, screw mandrel 32, slide block 33, and motor two 31 is fixedly connected On the inner side of the movable frame 24 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com