Low-temperature-resistant butterfly valve body and production process thereof

A production process and low temperature resistance technology, applied in the field of valve manufacturing, can solve the problem that the butterfly valve body cannot have both low temperature resistance and sealing performance, so as to avoid the diffusion and circulation of heat, improve the low temperature resistance, and improve the low temperature resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

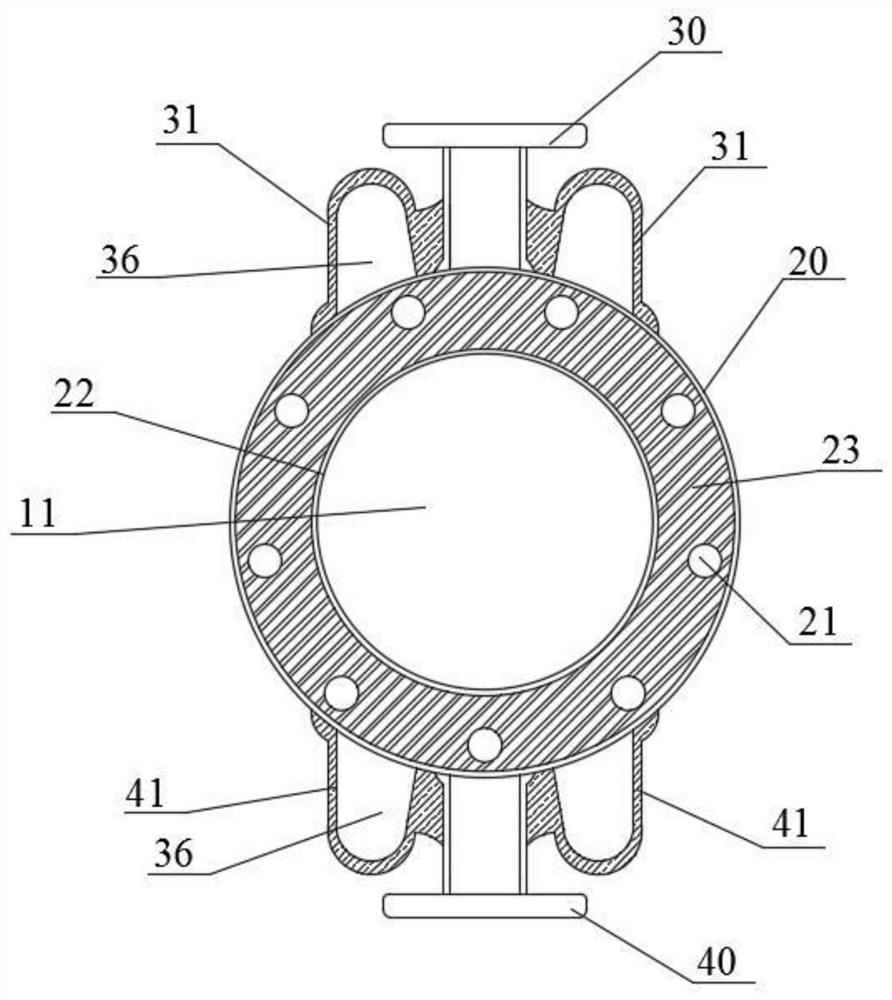

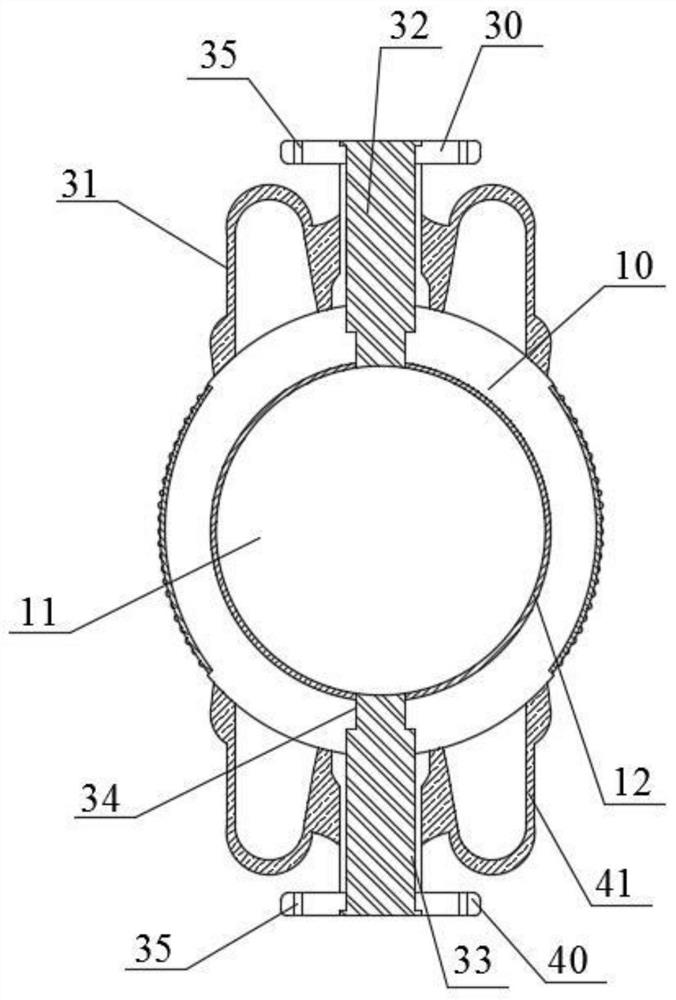

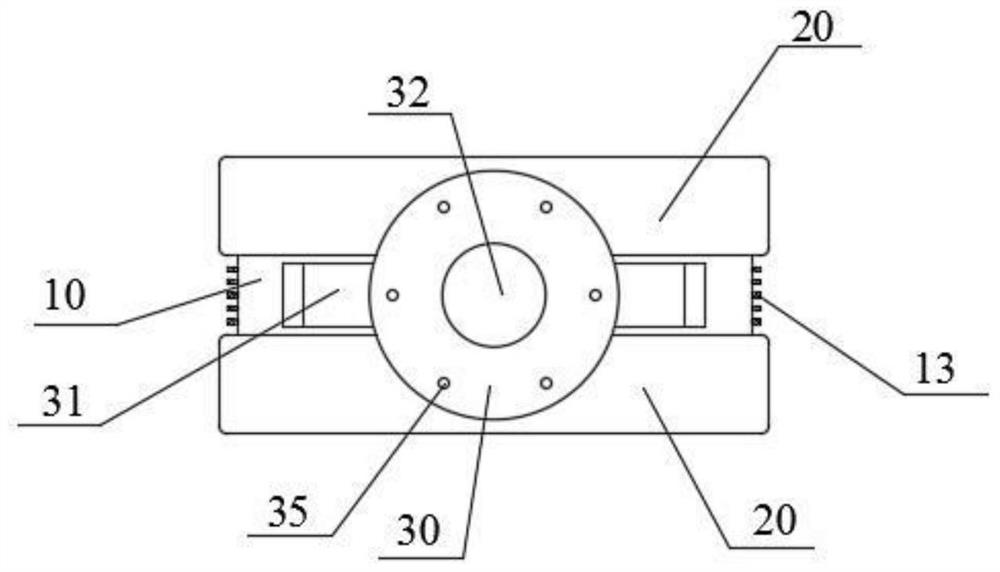

[0039] Such as Figure 1-4 As shown, this embodiment provides a low temperature resistant butterfly valve body, including a valve body body 10, flanges 20 are provided at both ends of the valve body body 10, and a center of the valve body body 10 and the flange 20 is provided with a Fluid channel 11; the top and bottom of the valve body main body 10 are located between the flanges 20 on both sides and are respectively provided with an upper valve shaft seat 30 and a lower valve shaft seat 40, and the two sides of the upper valve shaft seat 30 are arranged symmetrically with the valve body. The upper valve neck 31 of the main body 10 is integrally formed, and the lower valve neck 41 integrally formed with the valve body main body 10 is symmetrically provided on both sides of the lower valve shaft seat 40; The outer wall of 10 is provided with outer low temperature resistant structure.

[0040] The low temperature resistant butterfly valve body of this embodiment is improved on...

Embodiment 2

[0047] Such as Figure 5-6 As shown, the present embodiment provides a conveniently adjustable grinding and drilling equipment for butterfly valve body processing, including a frame 100, the upper sides of the frame 100 are respectively provided with a grinding mechanism 200, a drilling mechanism 300, and the grinding mechanism 200 and A clamping mechanism 400 is provided between the drilling mechanism 300; the grinding mechanism 200 is used to grind the end faces of the upper valve shaft seat 30 and the lower valve shaft seat 40 of the valve body body 10; The end faces of the seat 30 and the lower valve shaft seat 40 are drilled to obtain an end face hole 35; the clamping mechanism 400 is used to clamp the valve body main body 10 and perform position adjustment.

[0048] The grinding and drilling equipment clamps the valve body body 10 through the grinding mechanism 200, the drilling mechanism 300, and the clamping mechanism 400, and grinds the end faces of the upper valve sh...

Embodiment 3

[0060] Such as Figure 1-9 As shown, the present embodiment provides a production process of a low temperature resistant butterfly valve body, comprising the following steps:

[0061]The casting mold is made to have the same shape as the butterfly valve body with the valve body main body 10, the flange 20, the upper valve shaft seat 30, the lower valve shaft seat 40, the upper valve neck 31, and the lower valve neck 41, and place it with the fluid channel 11 , the center cavity 32, and the sand core with the same size as the gripping hole 36, the molten steel is poured into the casting mold through the ladle to obtain the valve body casting; wherein, the sand core is added by 94wt% to 96wt% of the original sand according to the weight ratio Prepared from 4wt%-6wt% water glass; the casting temperature is 1520-1540°C;

[0062] When the temperature of the casting mold is lowered to 920-980°C, the sand core is cleaned, the outer surface of the valve body body 10 and the flange 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com