Two-path white light interference differential measurement device and method

A white light interference and differential measurement technology, applied in the field of optical measurement, can solve the problems of positioning accuracy easily affected by noise, film surface wear, poor theoretical sensitivity, etc., to reduce measurement inconsistency, improve device signal-to-noise ratio, High sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

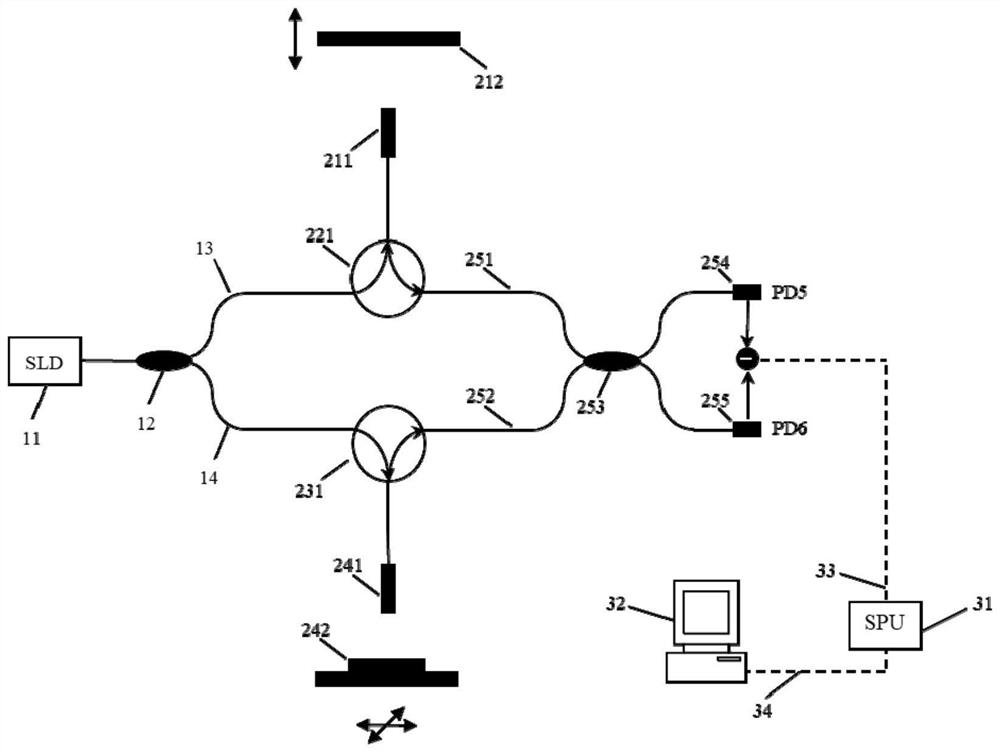

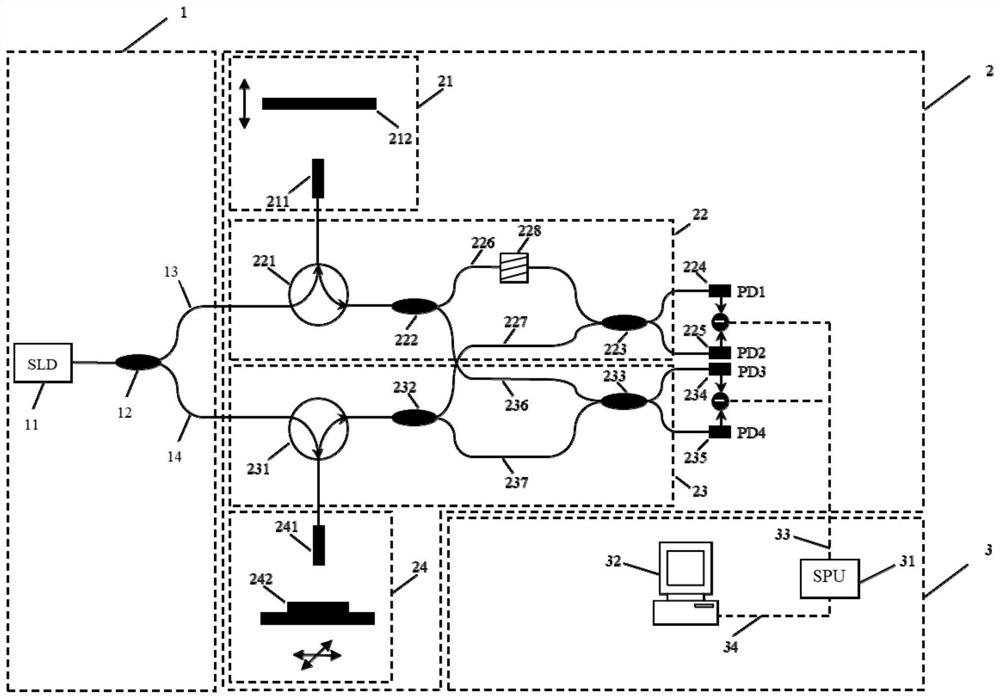

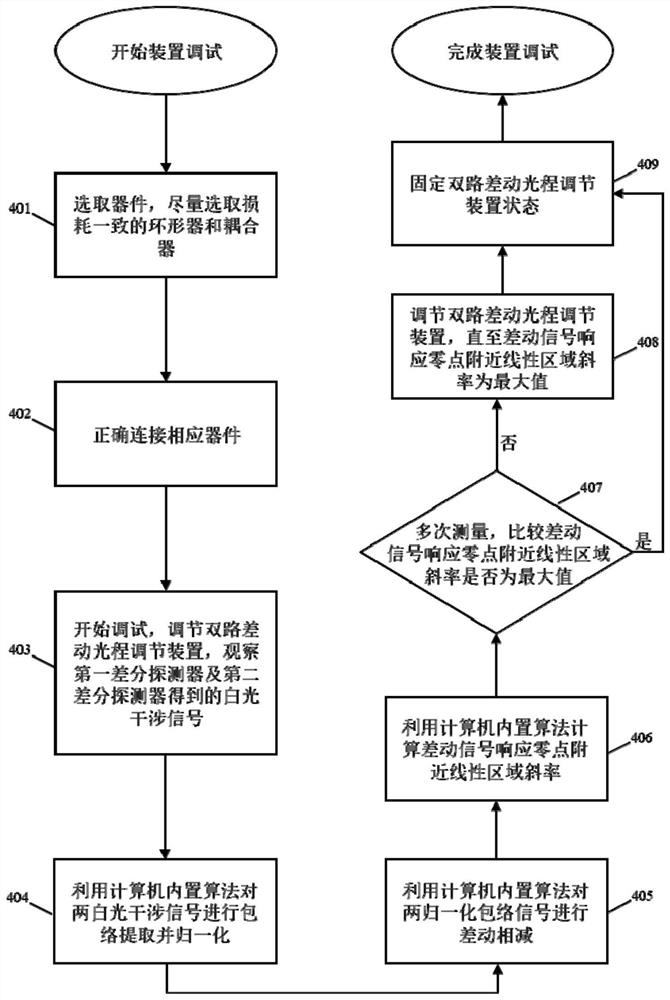

[0043] The present invention uses optical fiber optical path structure, based on white light interference principle and two-way differential detection principle, adopts the method of constructing optical path difference to obtain two-way white-light interference signal, obtains differential response signal after differential detection, and locates the location of differential response signal The zero-crossing position is used as an absolute reference position to realize the measurement of the size to be measured. This method has the advantages of high positioning accuracy, high sensitivity, and convenient signal demodulation, and can be widely used in the quantitative measurement of information such as thickness and surface topography of micro-nano devices.

[0044] A two-way white light interference differential measurement method of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com