Plasma processing device and heating device and working method thereof

A technology of heating device and processing device, which is applied to discharge tubes, electrical components, circuits, etc., to achieve the effect of improving the S2S distribution problem and the problem of uneven temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

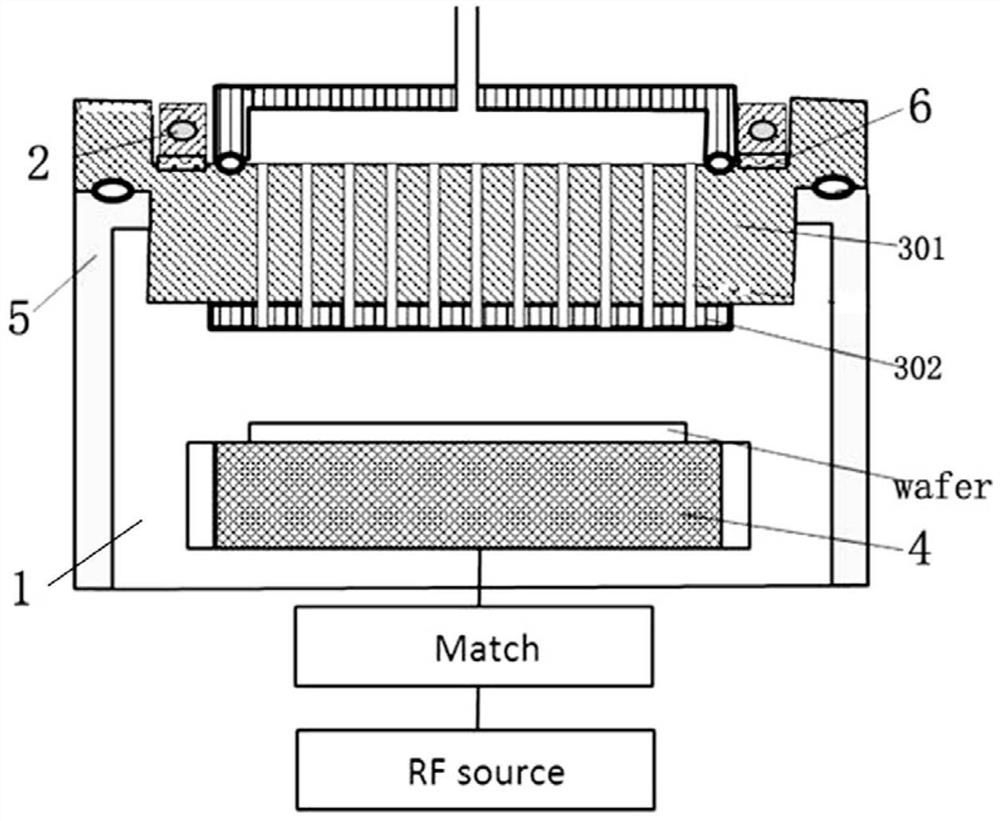

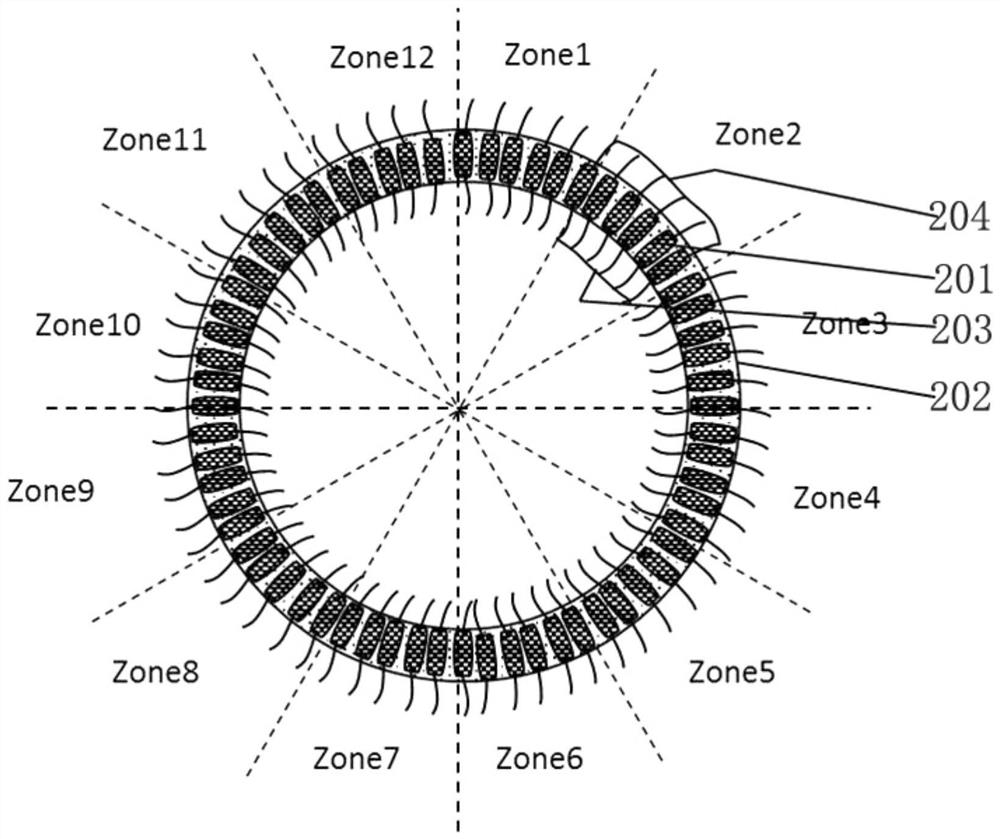

[0045] The heating device 2 includes several heating resistors 201 , a common heating source P0 and several controllers P. Among them, several heating resistors 201 are scattered and arranged in a circular ring, and the circular ring includes several zones along its circumference, which realizes the uniformity of heating provided by the heating resistors 201 and ensures the heating power received by each Zone. same;

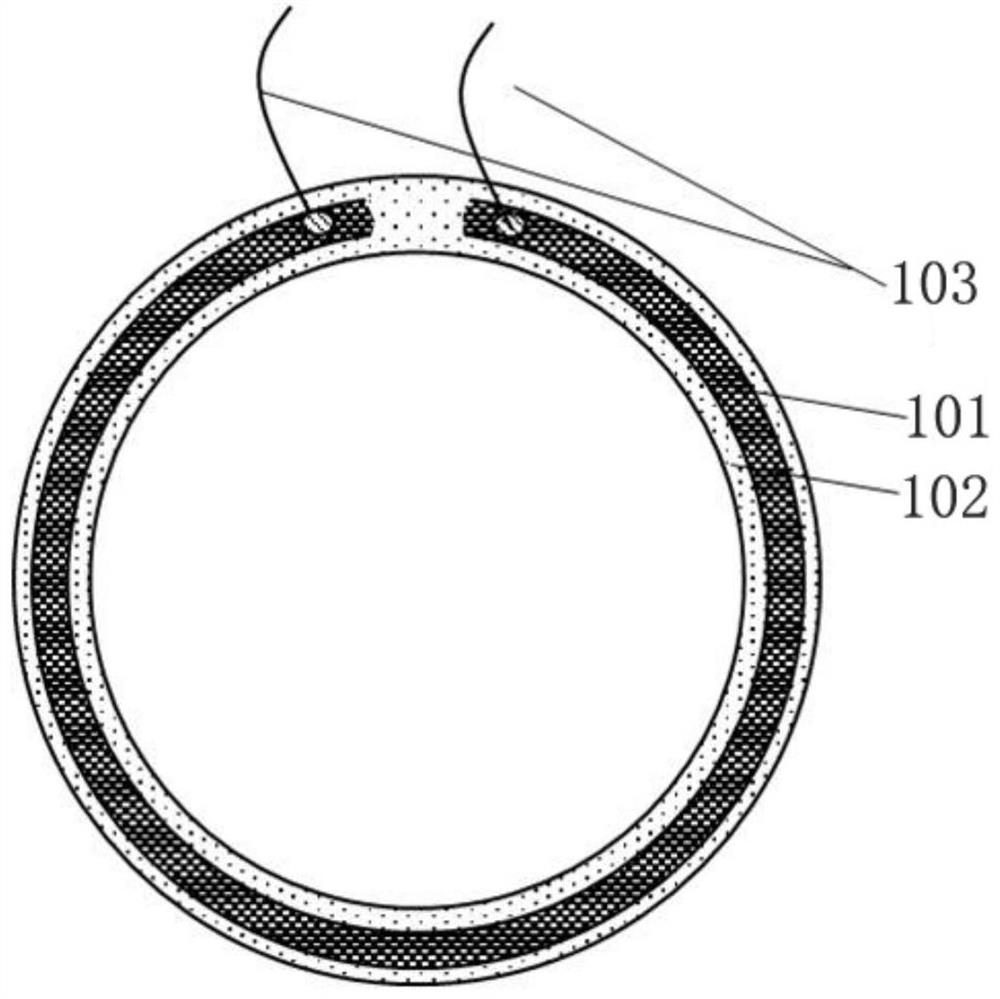

[0046] In Embodiment 1 of the present invention, the heating device 2 is discretely arranged as a plurality of surrounding heating resistors 201, which are evenly divided into several Zones, compared with the uneven heat generated at the inner and outer terminals 103 at the opening of the traditional heating resistor 101 This ensures that there is no longer a special cold spot (at the inner and outer terminals 103 at the opening of the traditional heating resistor 101) on the circumferential distribution of the heating resistor 201 of the heating device 2, and im...

Embodiment 2

[0063] The heating device 2 includes several heating resistors 201, a common heating source U0 and several controllers S. Among them, several heating resistors 201 are scattered and arranged in a circular ring, and the circular ring includes several zones along its circumference, which realizes the uniformity of heating provided by the heating resistors 201 and ensures the heating power received by each Zone. same;

[0064] In Embodiment 2 of the present invention, the heating device 2 is discretely arranged as a plurality of surrounding heating resistors 201, and is evenly divided into several Zones, compared with the uneven heat generated at the inner and outer terminals 103 at the opening of the traditional heating resistor 101 This ensures that there is no longer a special cold spot (at the inner and outer terminals 103 at the opening of the traditional heating resistor 101) on the circumferential distribution of the heating resistor 201 of the heating device 2, and improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com