Shield gate trench MOSFET manufacturing method

A manufacturing method and shielding grid technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., to achieve the effects of reducing production costs, wide use, and shortening processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The technical solution of the present application will be further described in detail below in conjunction with specific embodiments, but the protection scope of the present application is not limited to the following description.

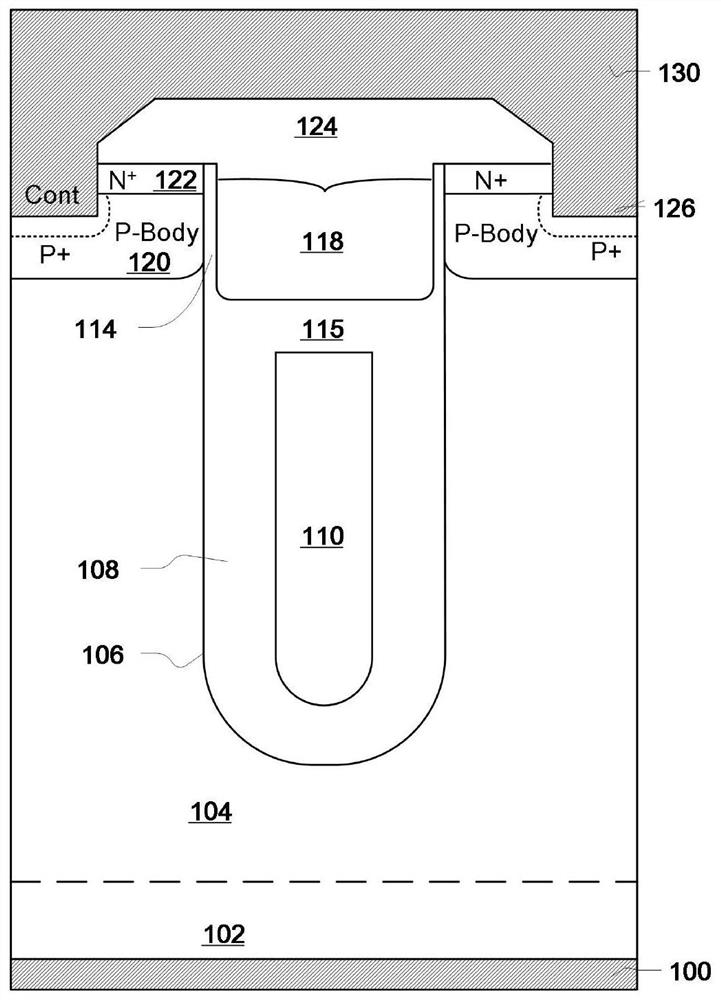

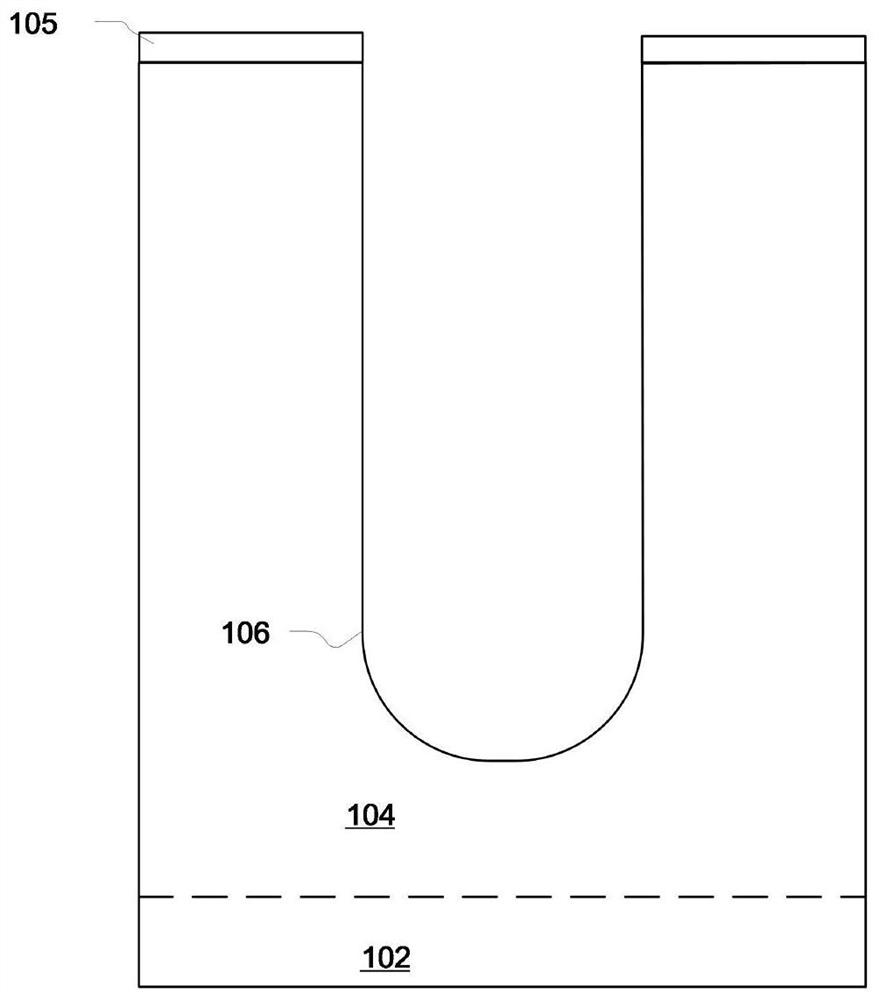

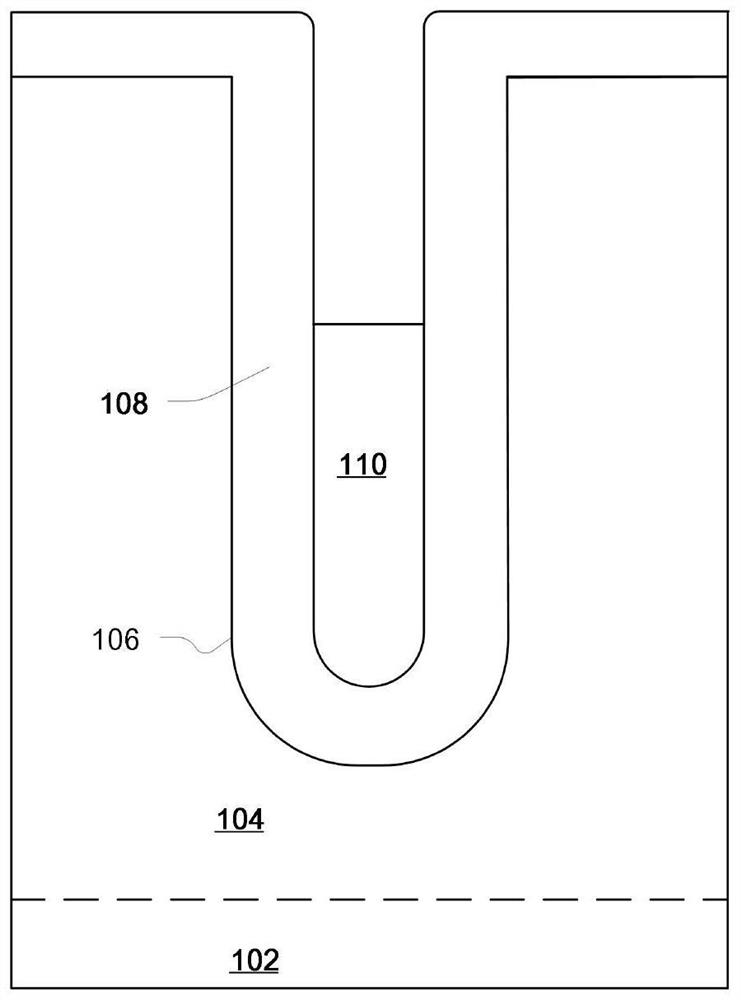

[0054] In some embodiments, a shielded gate trench MOSFET manufacturing method comprises growing a shielded gate oxide layer 108 on the sidewall of the trench 106 of the epitaxial layer 104, then filling the shielded gate polysilicon 110, and etching the shielded gate polysilicon 110 back to the first target depth;

[0055] Depositing a silicon nitride layer 112 with a target thickness T to form a dielectric isolation layer isolating the shielding gate polysilicon 110 and the gate polysilicon 118, and etching the silicon nitride layer 112 back to the surface of the epitaxial layer;

[0056] Etch the shielding gate oxide layer 108 to the second target depth, etch the silicon nitride layer 112 to the first target thickness K, so that the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com