3D printing porous interbody fusion cage

An intervertebral fusion cage and 3D printing technology, applied in the field of medical devices, can solve problems such as stress shielding and high elastic modulus, and achieve the effects of improving stability, improving mechanical strength, reducing displacement and even prolapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

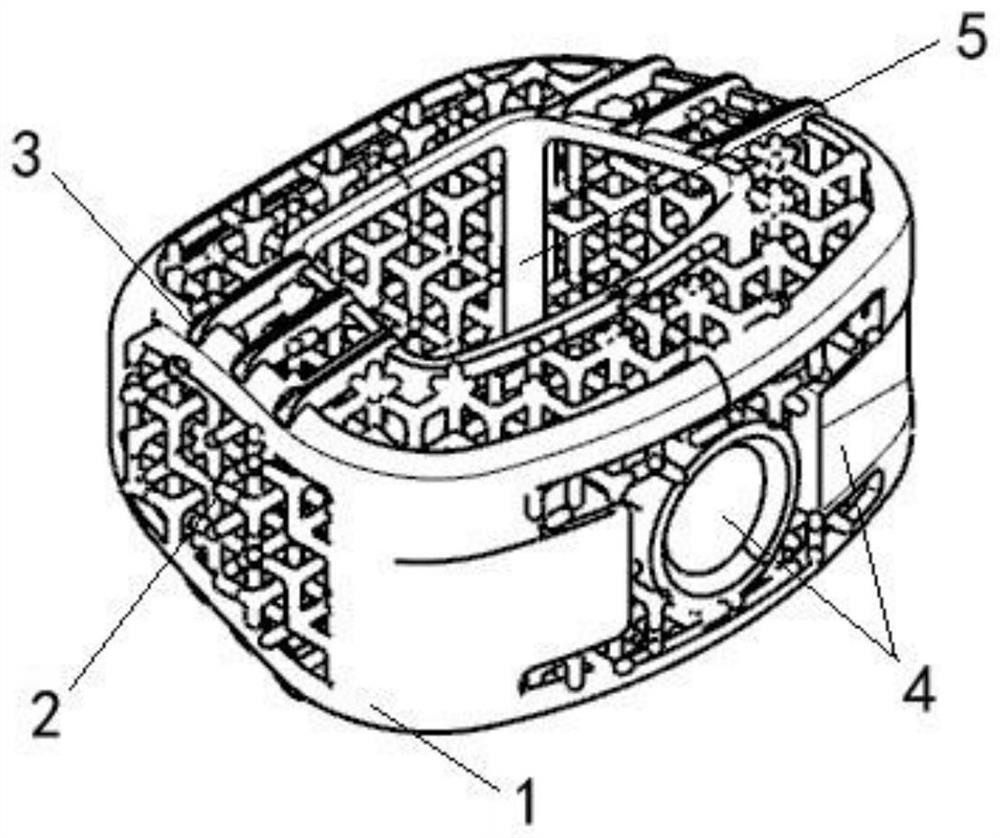

[0044] Such as Figure 1-5 Shown is a 3D printed porous intervertebral fusion device described in this embodiment, including a solid frame 1, a porous structure 2, occlusal teeth 3, a clamping mouth 4, and a bone graft chamber 5; the porous structure 2 is uniform It is filled inside the solid frame 1, so that the sides of the solid frame 1 are hollowed out, and the solid frame 1 is used as the main load-bearing structure to provide sufficient strength for the intervertebral cage. Specifically, as Figure 5 As shown, the interior or surface of the porous structure 2 is also provided with support beams 6; the upper and lower end faces of the solid frame 1 are respectively provided with a plurality of the occlusal teeth 3, and the occlusal teeth 3 arranged on the same side end faces of the solid frame 1 are arranged symmetrically. , the occlusal teeth 3 bite into the patient's spinal endplate to maintain the stability of the intervertebral fusion device; the solid frame 1 is provid...

Embodiment 2

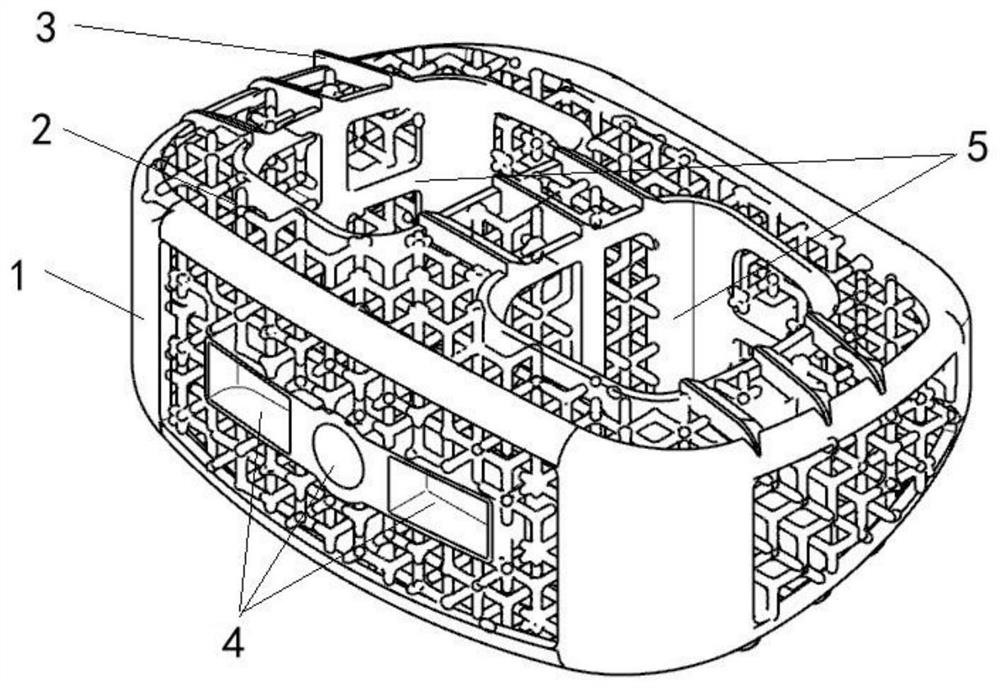

[0055] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that two bone graft bins 5 juxtaposed are designed on the porous type intervertebral fusion device, and the design of multiple bone graft bins 5 can adapt to larger porous type intervertebral fusion cages. The fusion device is guaranteed not to have a solid load-bearing structure in the central region of the porous intervertebral fusion device due to the oversized design of the bone graft chamber 5, resulting in uneven support for the spine.

Embodiment 3

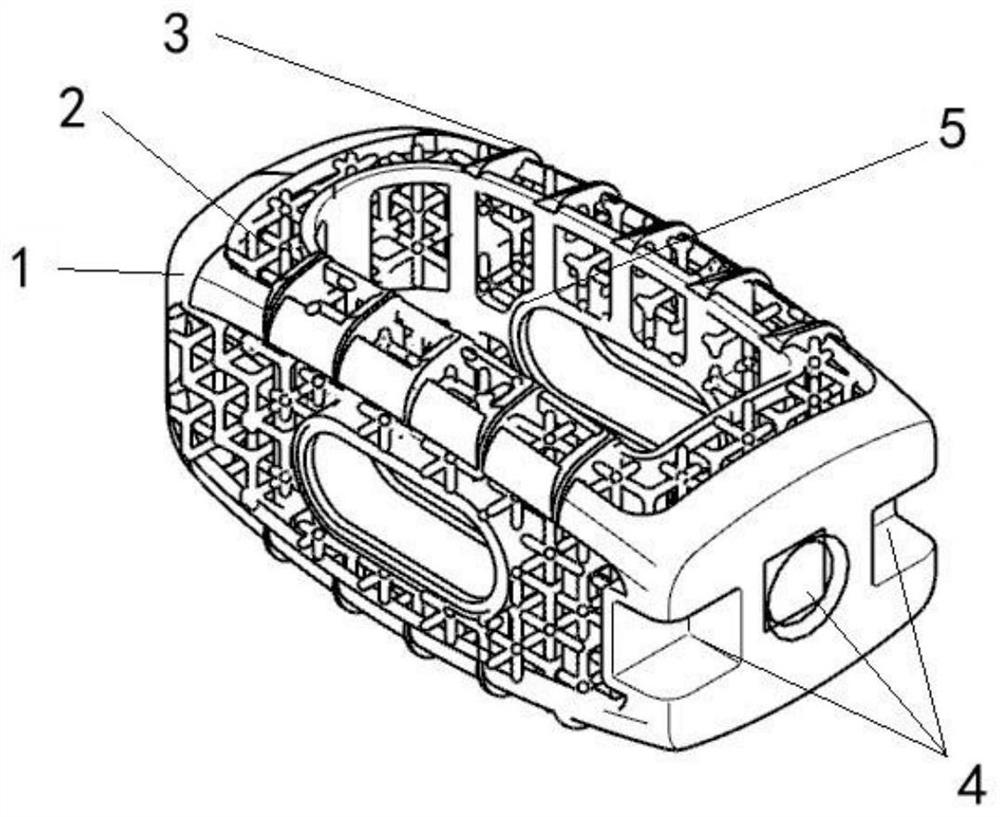

[0057] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the clamping port 4 is designed on the rear side of the porous intervertebral fusion device, which can be used for posterior approach surgery, while the solid frame 1 is designed as a long strip, and the doctor can Depending on the condition of the patient, only half of the intervertebral disc can be removed and a porous intervertebral fusion cage placed, or the entire intervertebral disc can be removed and two porous intervertebral fusion cages placed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com