Preparation method of arginine modified composite nanofiltration membrane

A composite nanofiltration membrane, arginine technology, applied in chemical instruments and methods, membrane, membrane technology and other directions, can solve the problems of poor pollution resistance, low flux of composite membrane, poor hydrophilicity of polyamide layer, etc. Achieve the effect of improving membrane fouling, wide application and improving hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

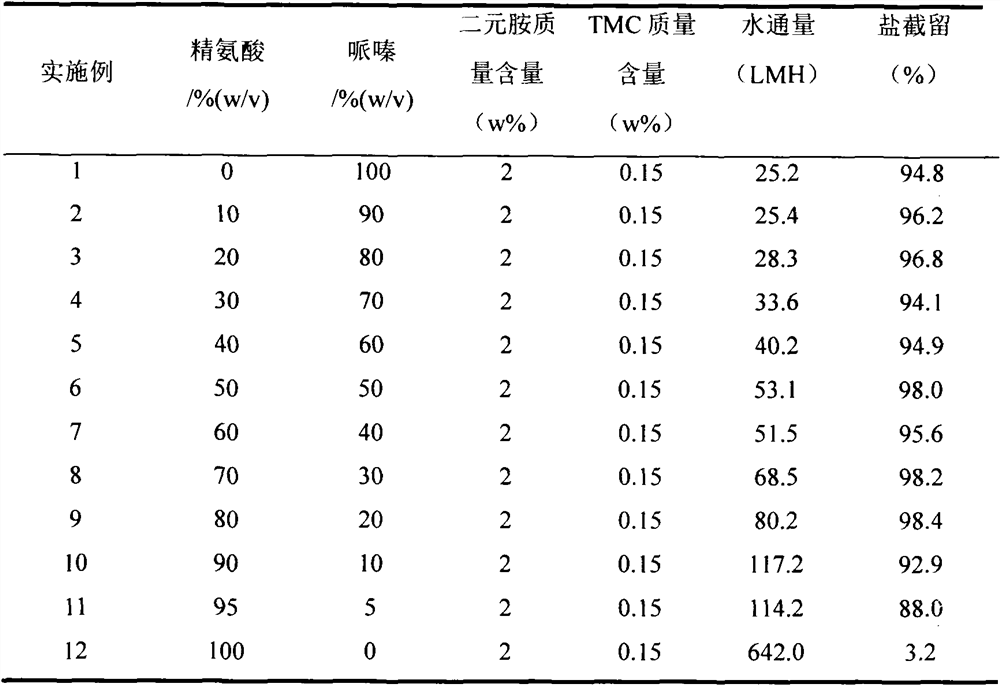

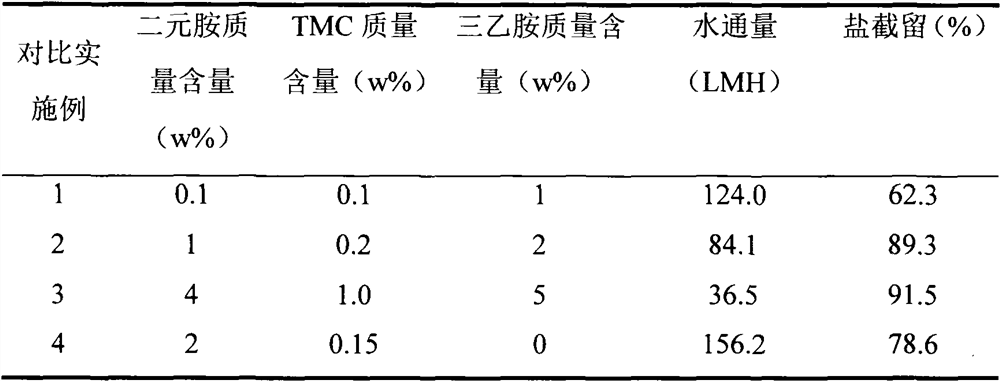

[0023] The ultrafiltration membrane is fully washed, immersed in an aqueous solution containing 2w% aliphatic amine monomer (the ratio of arginine and piperazine is shown in Table 1) and 3% triethylamine for 10min, and then removes residual moisture on the surface; The ultrafiltration membrane is immersed in the n-hexane solution containing 0.15w / v% trimesoyl chloride monomer and reacted for 1min; then the ultrafiltration membrane is placed in an oven at 60°C for 1min, and then taken out to obtain The polyamide-modified composite nanofiltration membrane was finally soaked in an environment of 25° C. for 48 hours to obtain a composite nanofiltration membrane containing L-arginine. Composite nanofiltration membrane at 0.6MPa, with 1000ppm Na 2 SO 4 The aqueous solution was tested for performance, and its water flux and salt rejection results are listed in Table 1.

[0024] Table 1 The formulation of Examples 1-12 and the water flux and salt rejection of the membrane

[0025] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com