Lanthanum ferrite perovskite material and preparation method and application thereof

A perovskite material, lanthanum ferrite technology, applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve the problems of gas production sensible heat loss, affecting production safety, biomass energy waste, etc., to achieve stability Good, enhanced removal rate, high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

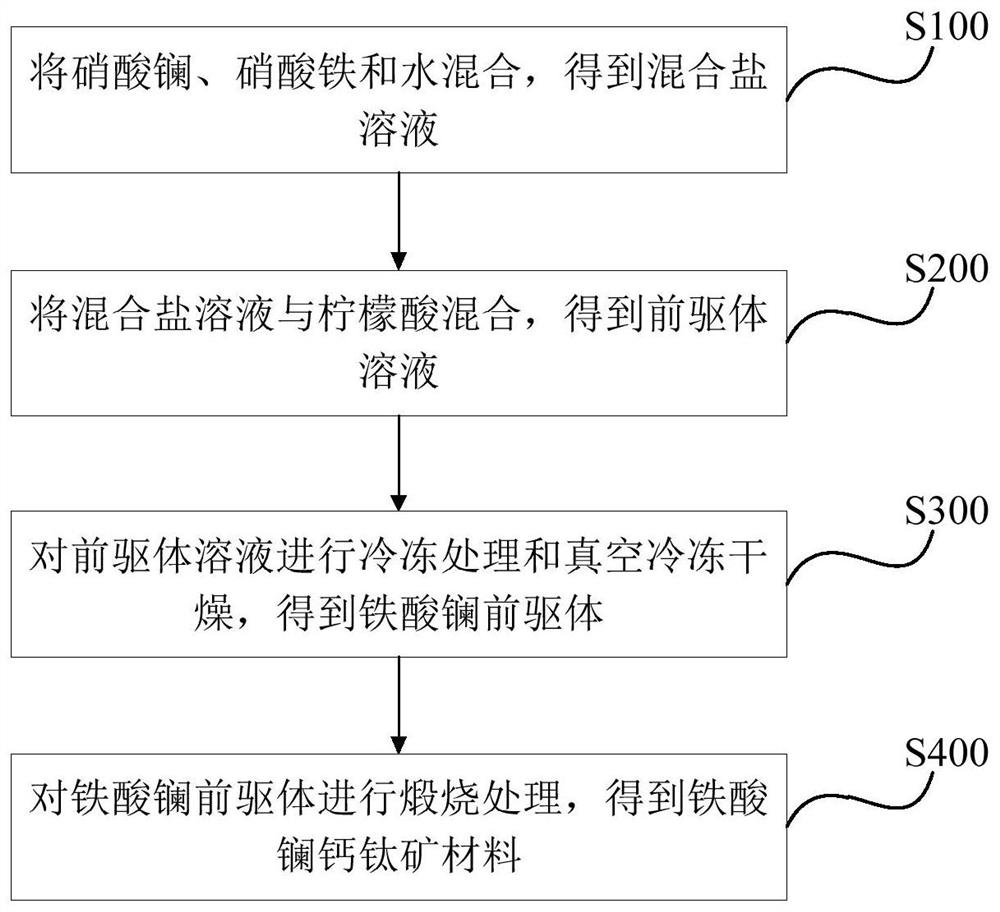

[0060] A preparation method of lanthanum ferrite perovskite (LFOC) material, comprising the following steps:

[0061] (1) According to the molar ratio La(NO 3 ) 3 :Fe(NO 3 ) 3 =1:1 Weigh an appropriate amount of La(NO 3 ) 3 and Fe(NO 3 ) 3 Dissolve the powder in deionized water, stir thoroughly in a water bath at 45°C for 30 minutes, then add an aqueous solution of citric acid according to the molar ratio of metal cations to citric acid at 1:1, and stir thoroughly in a water bath at 45°C for 30 minutes. The mixed liquid was frozen in a -80°C refrigerator for 24 hours, and the frozen sample was dried in a vacuum chamber for 24 hours at a temperature of -60°C and a pressure of 10Pa.

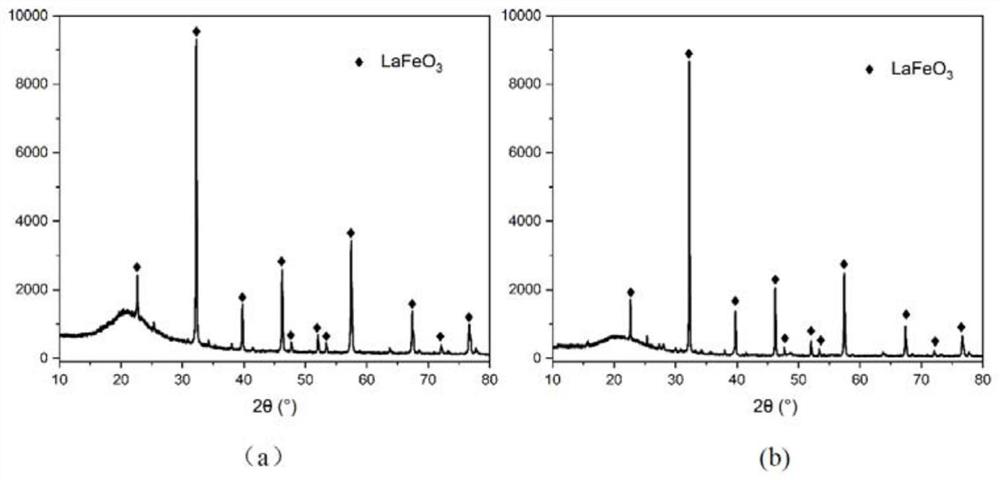

[0062] (2) The dried solid was placed in a muffle furnace, heated from room temperature to 400°C at a heating rate of 5°C / min, and calcined at a constant temperature for 4 hours, then raised to 900°C at a heating rate of 4°C / min, and calcined at a constant temperature for 4 hours. After coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com