Coal gasification grey water dispersing agent and application thereof

A dispersant and coal gasification technology, which is applied in natural water treatment, descaling and water softening, chemical instruments and methods, etc., can solve the problems of high cost of use, and achieve low treatment costs, easy cleaning, and high-efficiency sterilization and algae killing capabilities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

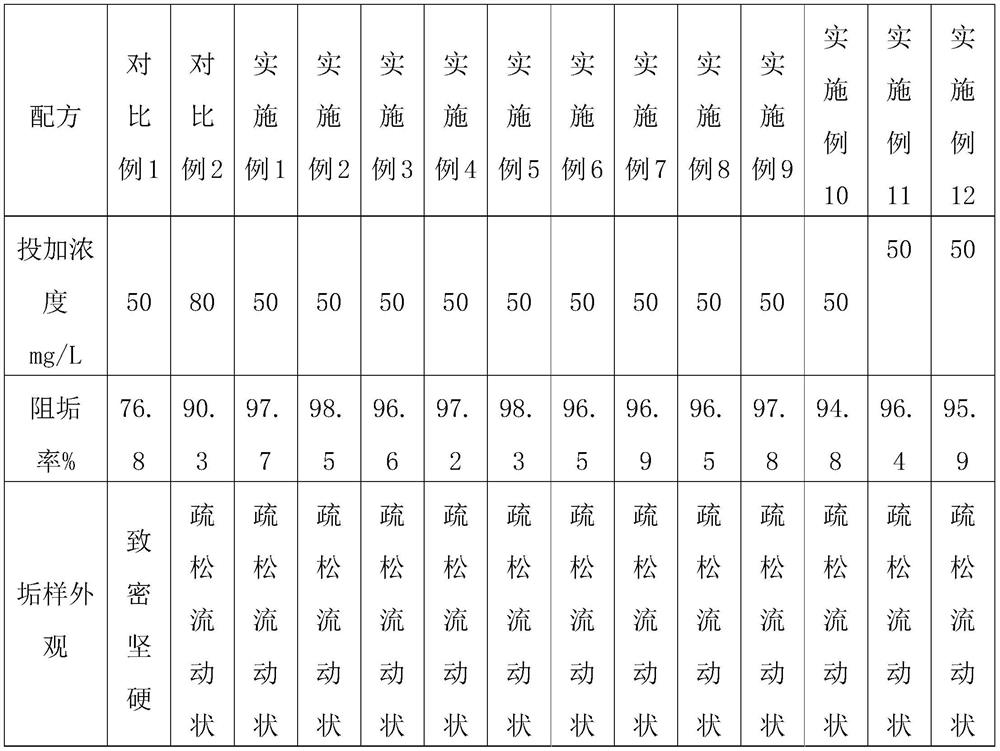

Examples

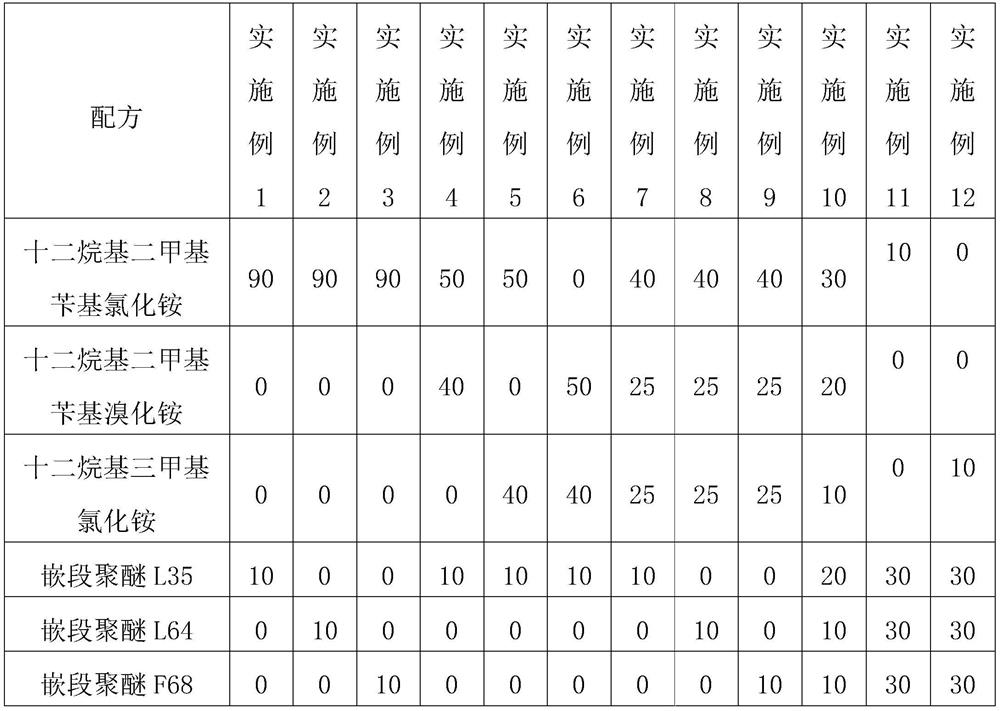

Embodiment 1

[0015] A coal gasification ash water dispersant, which comprises 90% of dodecyl dimethyl benzyl ammonium chloride (1227) and 10% of block polyether L35 dissolved in deionized water in terms of dry weight. made.

Embodiment 2

[0017] A coal gasification ash water dispersant, which comprises 90% dodecyl dimethyl benzyl ammonium chloride (1227) and 10% block polyether L64 dissolved in deionized water by dry weight and compounded made.

Embodiment 3

[0019] A coal gasification ash water dispersant, which comprises 90% dodecyl dimethyl benzyl ammonium chloride (1227) and 10% block polyether F68 dissolved in deionized water on a dry weight basis made.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com