Preparation method and production device of large-particle spherical glass

A production device and large particle technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of low flatness of contact graphite surface, high roundness of glass balls, complicated process, etc., and achieve color stability and strengthening High temperature separation, the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] step one:

[0050] Soda-lime-silica glass frit is melted and water-quenched, spread on a plate and placed in an oven to dry at 100°C for 5 hours. The dried water-quenched frit is crushed with a crusher. After the crushing is completed, it is Pass through a 10-mesh sieve and a 30-mesh sieve in turn, leaving a water-hardened glass frit of an intermediate size;

[0051] Step two:

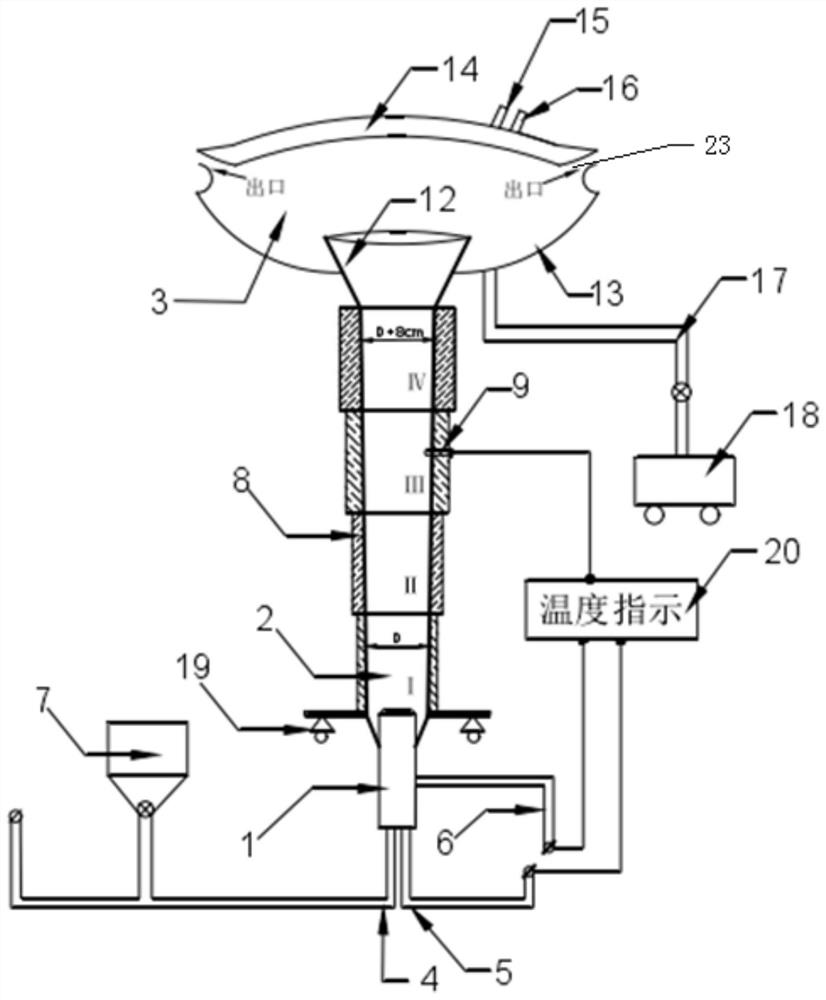

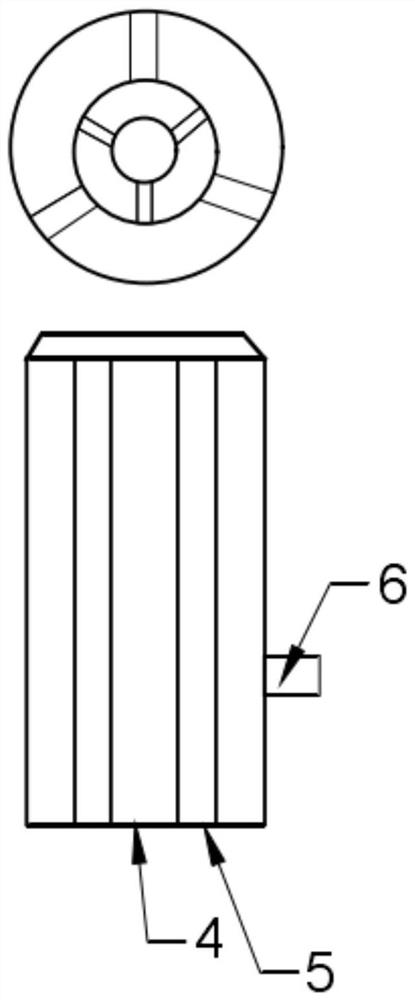

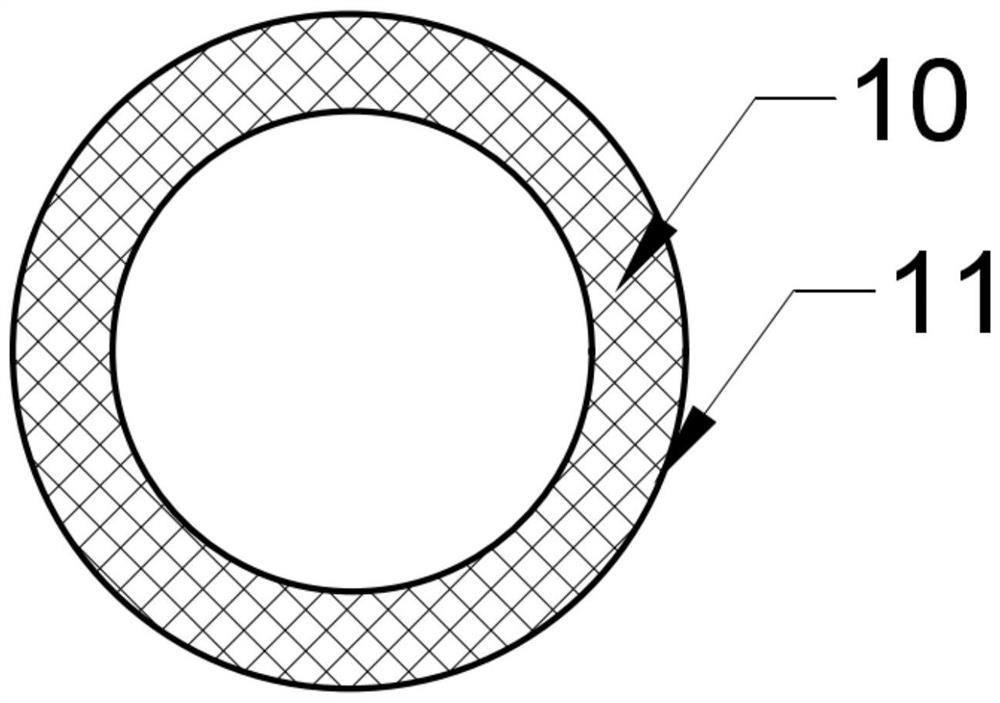

[0052] Beading using a beading device:

[0053] First, turn on the natural gas pipeline switch by controlling the temperature indicator, and then use an open flame to ignite the natural gas, then control the temperature indicator to open the oxygen pipeline switch to supply oxygen, and at the same time manually open the compressed air switch to supply compressed air. Adjust the flow of air, natural gas, and oxygen by the degree of closure of the switch until the length of the flame just reaches the top cover. After the temperature of the furnace body reaches 900°C, keep it warm for 30 minutes...

Embodiment 2

[0057] step one:

[0058] After the glass frit of borosilicate glass is melted and water-quenched, spread it on a plate and put it in an oven to dry at 100°C for 5 hours. Use a crusher to break the dried water-quenched glass frit. After the crushing is completed, put It passes through a 10-mesh sieve and a 30-mesh sieve in turn, leaving a water-hardened glass frit of an intermediate size;

[0059] Step two:

[0060] Beading using a beading device:

[0061] First, turn on the natural gas pipeline switch by controlling the temperature indicator, and then use an open flame to ignite the natural gas, then control the temperature indicator to open the oxygen pipeline switch to supply oxygen, and at the same time manually open the compressed air switch to supply compressed air. Adjust the flow of air, natural gas, and oxygen by the degree of closure of the switch until the length of the flame just reaches the top cover. After the temperature of the furnace body 2 reaches 950°C, k...

Embodiment 3

[0065] step one:

[0066] After the glass frit of high-alumina glass is melted and water-quenched, spread it on a plate and put it in an oven to dry at 100°C for 5 hours. Use a crusher to crush the dried water-quenched frit. After the crushing is completed, it is sequentially Pass through a 10-mesh sieve and a 30-mesh sieve, leaving a water-hardened glass frit of an intermediate size;

[0067] Step two:

[0068] Beading using a beading device:

[0069] First, turn on the natural gas pipeline switch by controlling the temperature indicator, and then use an open flame to ignite the natural gas, then control the temperature indicator to open the oxygen pipeline switch to supply oxygen, and at the same time manually open the compressed air switch to supply compressed air. Adjust the flow of air, natural gas, and oxygen by the degree of closure of the switch until the length of the flame just reaches the top cover. After the temperature of the furnace body 2 reaches 1000°C, keep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com