Water-based fluorescent ink as well as preparation method and application thereof in full-color printing and encryption anti-counterfeiting

A fluorescent ink, water-based technology, applied in the production of special varieties of printed matter in the direction of printing, application, ink, etc., can solve the problems of complex production process, forgery, poor ink stability and other problems of oil-soluble fluorescent ink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

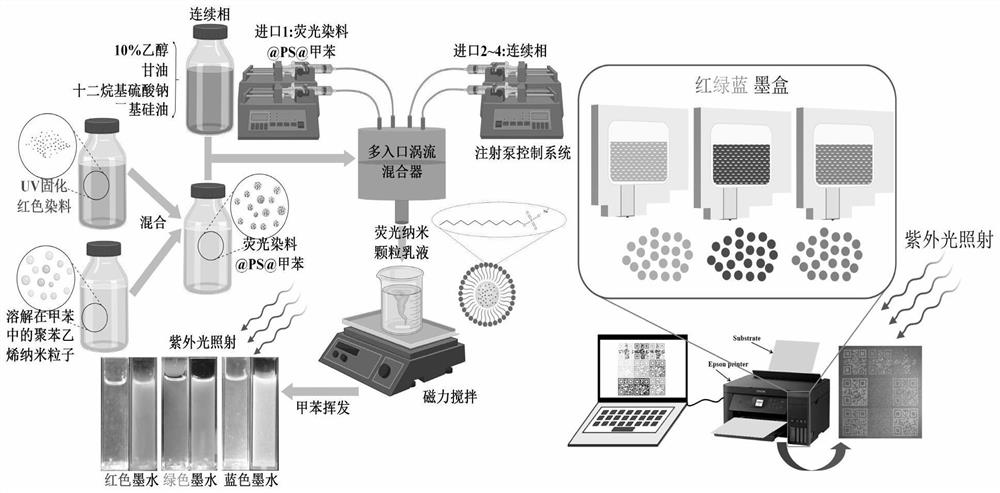

[0070] The present invention also provides the preparation method of the water-based fluorescent ink described in the above scheme, comprising the following steps:

[0071] Dispersing polystyrene beads in toluene to obtain polystyrene nanoparticles toluene solution;

[0072]Mixing UV-cured fluorescent dye and polystyrene nanoparticle toluene solution to obtain fluorescent dye-polystyrene nanoparticle toluene solution; the UV-cured fluorescent dye is UV-cured red, green or blue fluorescent dye;

[0073] Mix ethanol, water, glycerol and surfactant to obtain a continuous phase;

[0074] The fluorescent dye-polystyrene nanoparticle toluene solution and the continuous phase were subjected to shear emulsification in a four-jet multi-inlet vortex mixer to obtain a fluorescent dye-polystyrene nanoparticle toluene emulsion.

[0075] The toluene in the fluorescent dye-polystyrene nanoparticle toluene emulsion is volatilized and removed to obtain the water-based fluorescent ink.

[007...

Embodiment 1

[0101] (1) First, dissolve and disperse polystyrene (PS) pellets with a weight average molecular weight of 192,000 in toluene to prepare polystyrene nanoparticle toluene solution, wherein the mass fraction of PS is 1% (referred to as 1%PS@toluene ). During the preparation process, PS beads are added in batches and the dispersion process of PS beads is accelerated by ultrasound, so as to ensure that the PS nanoparticles dispersed in toluene have a smaller particle size and uniform distribution.

[0102] (2) Add red fluorescent dye to 1% PS@toluene, control the mass fraction of red fluorescent dye in the red fluorescent dye-polystyrene nanoparticle toluene solution to be 5%, and vortex 30s on the vortex instrument, make the dye Mix well with PS to obtain a red fluorescent dye-polystyrene nanoparticle toluene solution (recorded as 5% Red dye@1%PS@toluene).

[0103] (3) Prepare ink continuous phase: first prepare 10% ethanol aqueous solution, then mix 10% ethanol aqueous solution...

Embodiment 2

[0109] Other conditions are consistent with embodiment 1, only in step (2), the mass fraction of red fluorescent dye in control red fluorescent dye-polystyrene nanoparticle toluene solution is respectively 1%, 3%, 5%, 7% and 10% %; The concentration of SDS in the ink continuous phase is controlled to be 20mg / mL in step (3). Test the fluorescent intensity of gained water-based fluorescent ink, the obtained result is as follows Figure 7 shown, according to Figure 7 It can be seen that the fluorescence intensity of the ink increases with the increase of the fluorescent dye content.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com