Method for preparing liquid soil conditioner from amino acid waste liquid

A soil conditioner and amino acid technology, applied in the field of lysine production, can solve the problems of increased production cost, large investment, complicated process, etc., and achieve the effects of increasing value, good effect and improving extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. High-speed disc separation of fermentation broth

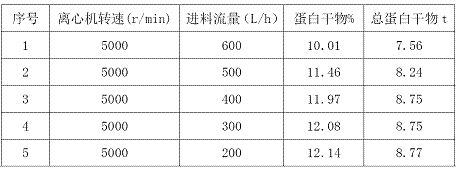

[0026] To explore the feasibility of disc separation fermentation broth, take 1000L of fermentation broth, add chitosan 100g, stir at 500rpm for 30s, let it stand for 3min, then set the speed of high-speed disc separator at 5000r / min, by changing the feed flow rate, detect different Supernatant protein dry matter content under the feed flow rate, test the optimal feed flow rate under the rotating speed of 5000r / min. See Table 1 for details:

[0027] Table 1

[0028]

[0029] According to comprehensive experimental analysis, the optimal feed rate is 300-400L / h at the speed of 5000r / min of the high-speed disc separator. At this speed, there are more dry protein, less time-consuming and less energy consumption.

[0030] The removal rates of bacteria with and without chitosan were 98.5% and 87.1%, respectively. The invention does not need to add a large amount of chitosan to form a large floc, but only needs a smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com