Efficient fluoride-free etching solution for copper-molybdenum alloy film

A technology of copper-molybdenum alloy film and etching solution, which is applied in the field of metal etching, can solve the problems of high operating risk, etching glass substrate, loss and other problems of operators, and achieve the effect of high efficiency and safety of etching, meeting etching requirements and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

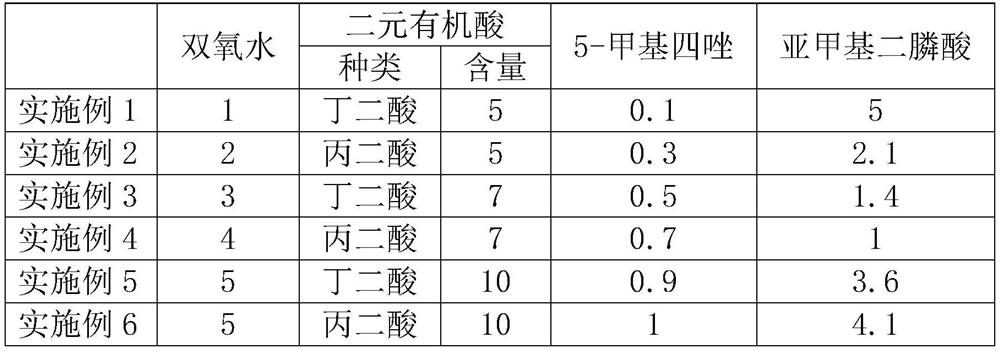

[0017] The high-efficiency fluorine-free copper-molybdenum alloy film etching solution of preparation embodiment 1-6 is mixed according to the formula of table 1:

[0018] Table 1: Unit: wt%

[0019]

[0020] Note: The part less than 100wt% in the content is supplemented by deionized water.

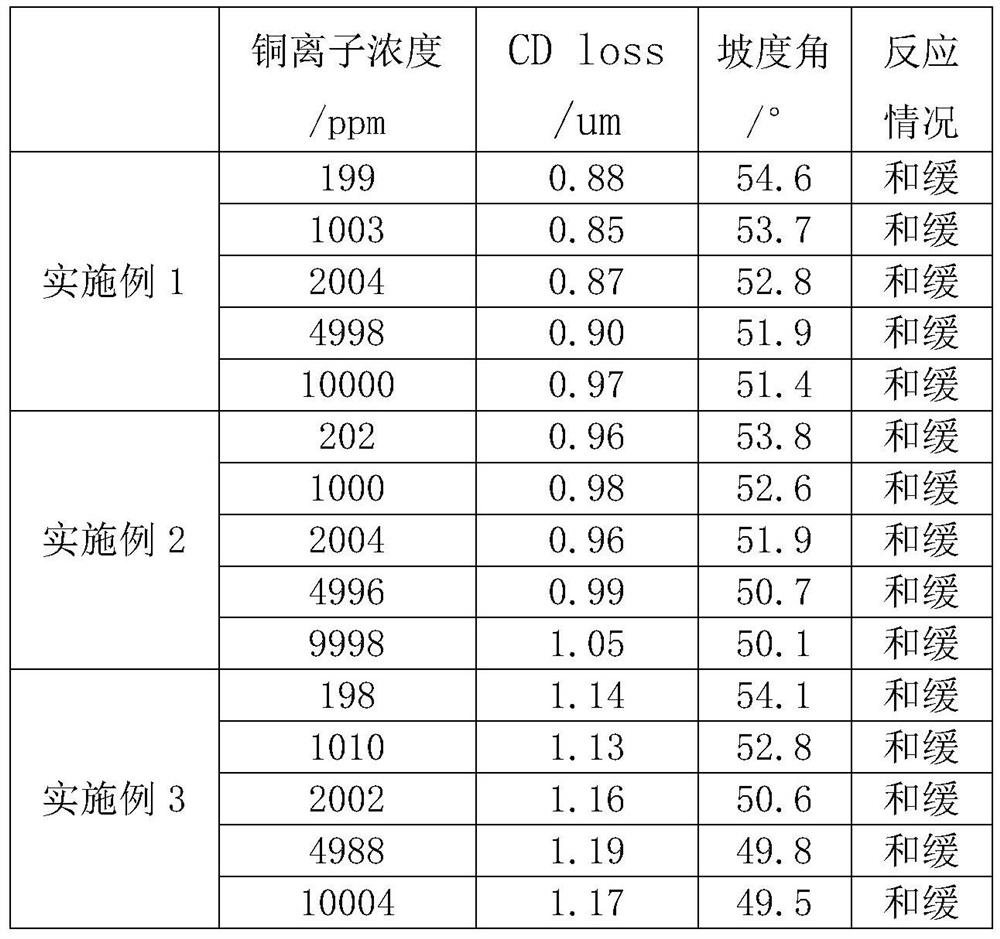

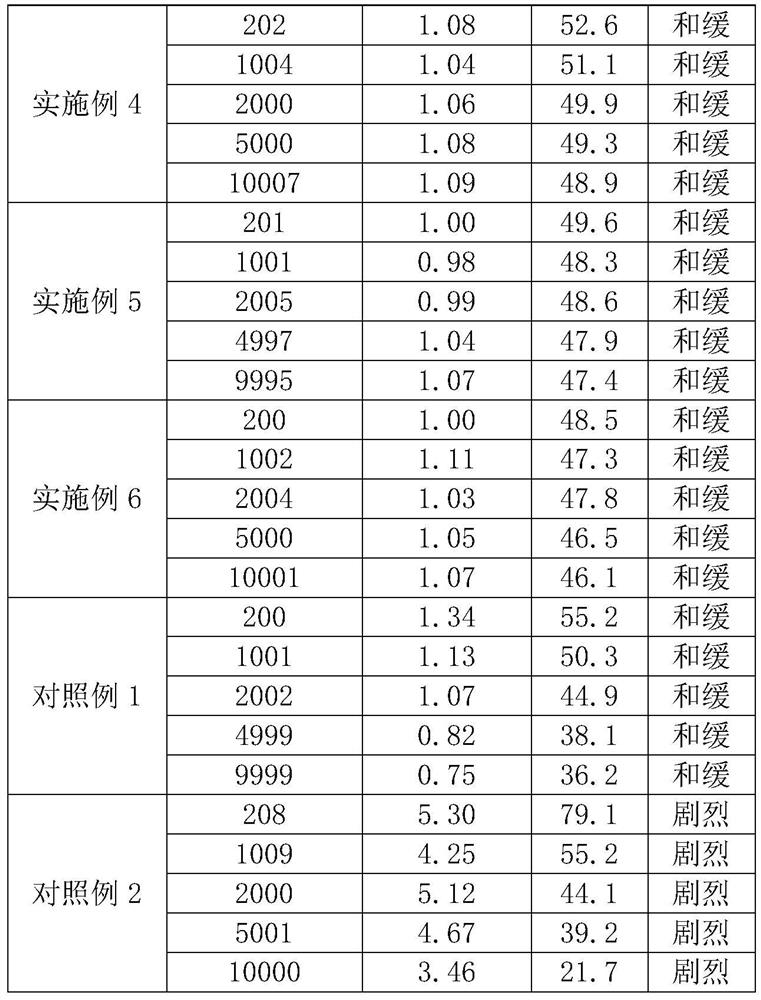

[0021] Using 40wt% hydrogen fluoride as comparative example 1 and 50wt% hydrogen peroxide as comparative example 2, a comparative experiment was carried out with the etchant of Examples 1-6. The experimental method is to vertically immerse a substrate with a size of 2cm×2cm, a molybdenum thickness of 30nm, and a copper thickness of 500nm with a developer coated on the surface of the copper layer in the etchant, and perform etching at 30-32°C until the molybdenum layer is etched completely. Remove and add a new substrate to continue etching. Taking the concentration of copper ions as a characterization, take the etched products at the concentration of 200ppm, 1000ppm, 2000ppm, 5000ppm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com