Vertical greening lower glass curtain wall and suspended ceiling aluminum plate conversion structure and construction method

A vertical greening and glass curtain wall technology, which is applied in the direction of walls, ceilings, building components, etc., can solve the problems of easy damage to the fixed part of the glass curtain wall, complicated fixing structure, and many installation procedures, so as to achieve shortened construction period, good sealing effect, and convenient installation. The effect of edge installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

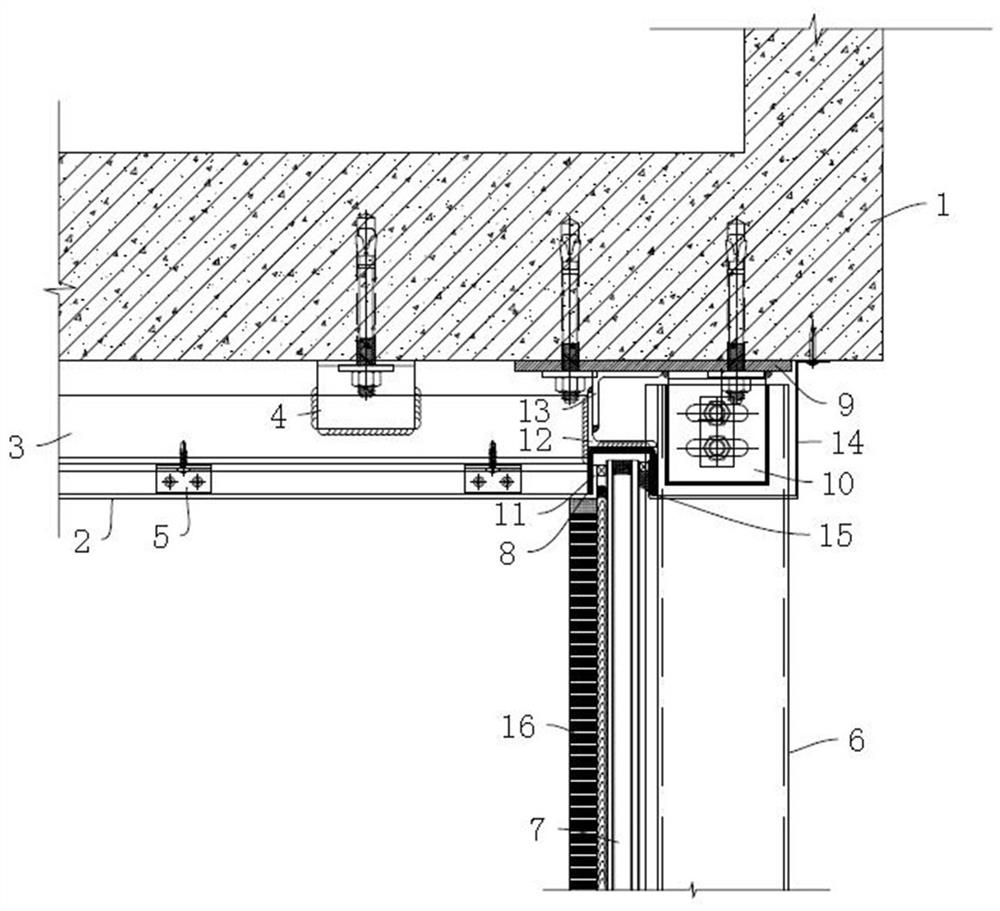

[0033] Such as figure 1 As shown, the present invention discloses a conversion structure and construction method of a glass curtain wall and a suspended ceiling aluminum plate under vertical greening. The conversion structure includes a suspended ceiling system and a curtain wall system arranged at the end of the suspended ceiling system.

[0034] The ceiling system includes a ceiling joist fixed on the top surface of the building structure 1 and an aluminum veneer 2 installed on the ceiling joist. A plurality of fixed angle steels 4 are arranged at intervals along the length direction of the ceiling keel. The ceiling angle steel 3 is L50*4 hot-dip galvanized angle steel, the fixed angle steel 4 is L50*4 hot-dip galvanized angle steel with a length of 70mm, the fixed angle steel 4 is anchored with the building structure 1 by chemical bolts, and the fixed angle steel 4 is welded to the ceiling angle steel 3 fixed. The aluminum veneer 2 is fixedly connected to the ceiling angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com