A multi-plate friction-hydraulic composite brake support bridge

A compound brake and friction brake technology, applied in the direction of liquid resistance brakes, brakes, brake components, etc., can solve the difficulty of choosing the installation position of the retarder, the slow response speed of the hydraulic retarder, and the inability to provide braking force in time, etc. problem, to achieve high braking effect and safety, reduce the quality of the whole bridge, and improve the effect of braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below with reference to the accompanying drawings.

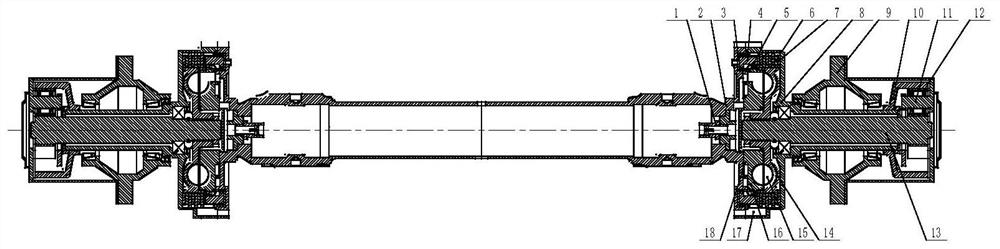

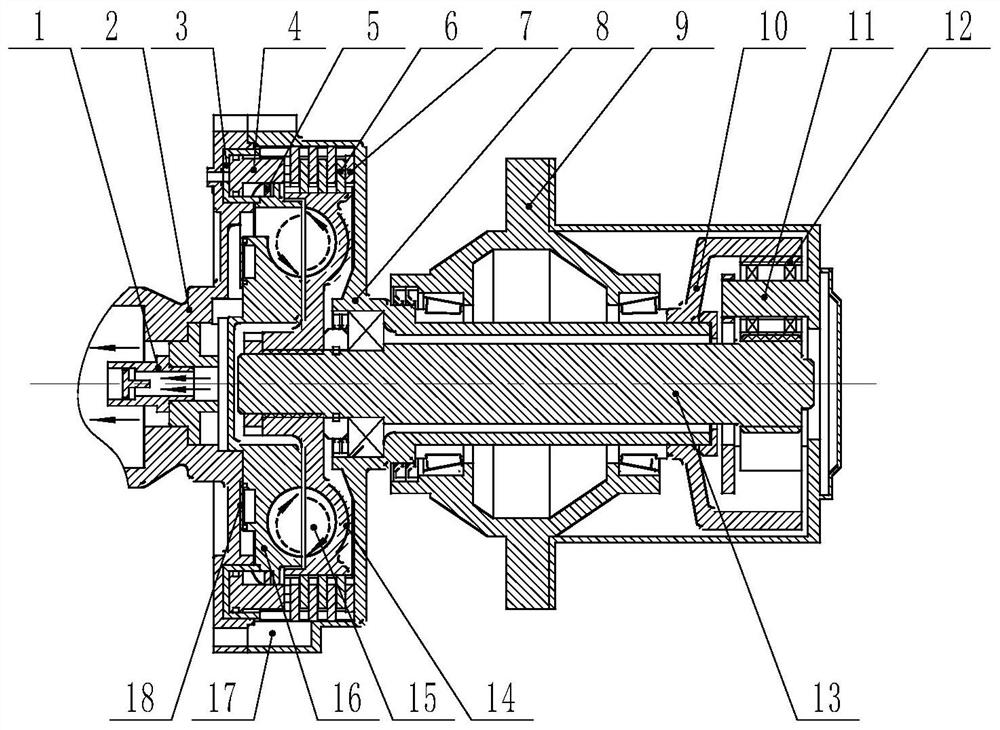

[0028] like figure 1 As shown, it is an assembly diagram of a multi-plate friction-hydraulic composite brake support bridge of the present invention, including a support bridge part, a hydraulic retarder part, a multi-plate friction brake part, and a speed increasing mechanism part.

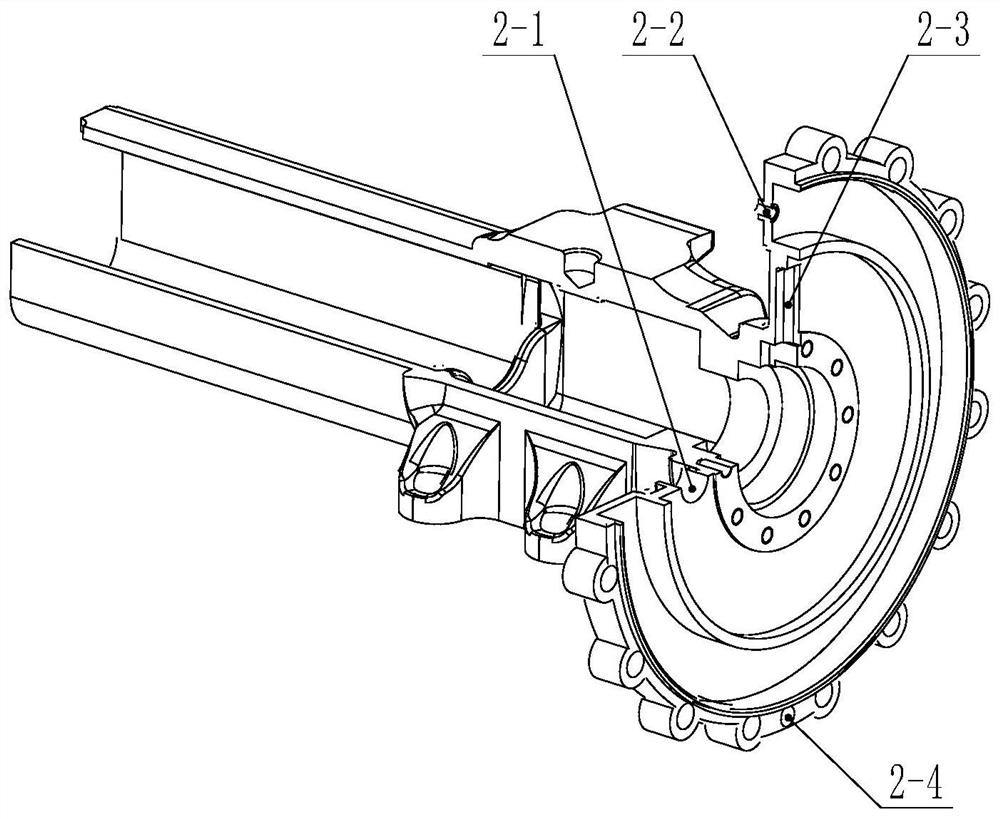

[0029] The supporting bridge part includes a supporting axle housing 2, a wheel side axle housing 8 and a wheel hub 9. The supporting axle housing 2 is provided with a working fluid inlet 2-1 and an air inlet 2-2 on the side close to the wheel side. The liquid inlet 2-1 enters the liquid inlet channel 16-1, and the water channel isolation plate 18 separates the liquid outlet channel 2-3 from the liquid inlet channel 16-1, and the two do not interfere with each other. The air inlet 2-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com