Hydraulic valve plate assembly of new energy vehicle and transmission

A technology of new energy vehicles and hydraulic valves, which is applied to transmission parts, components with teeth, belts/chains/gears, etc., can solve problems such as poor heat dissipation, reduce frustration and ensure smoothness and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

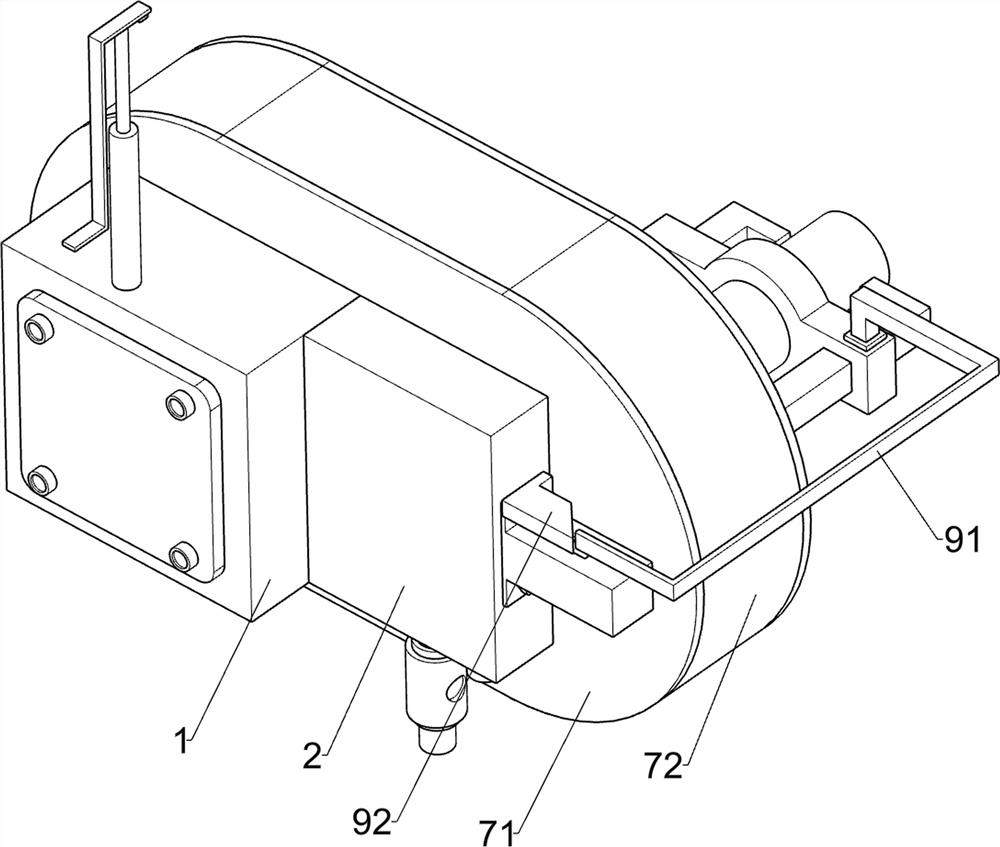

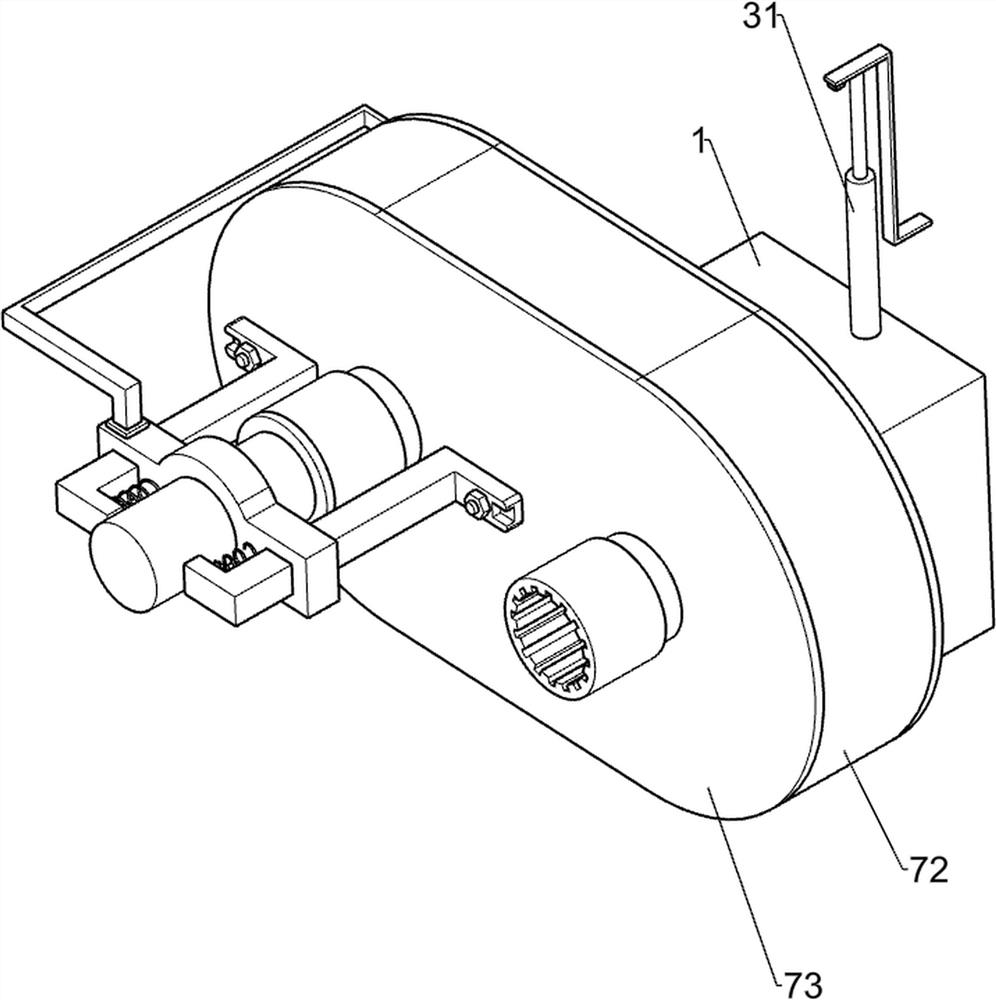

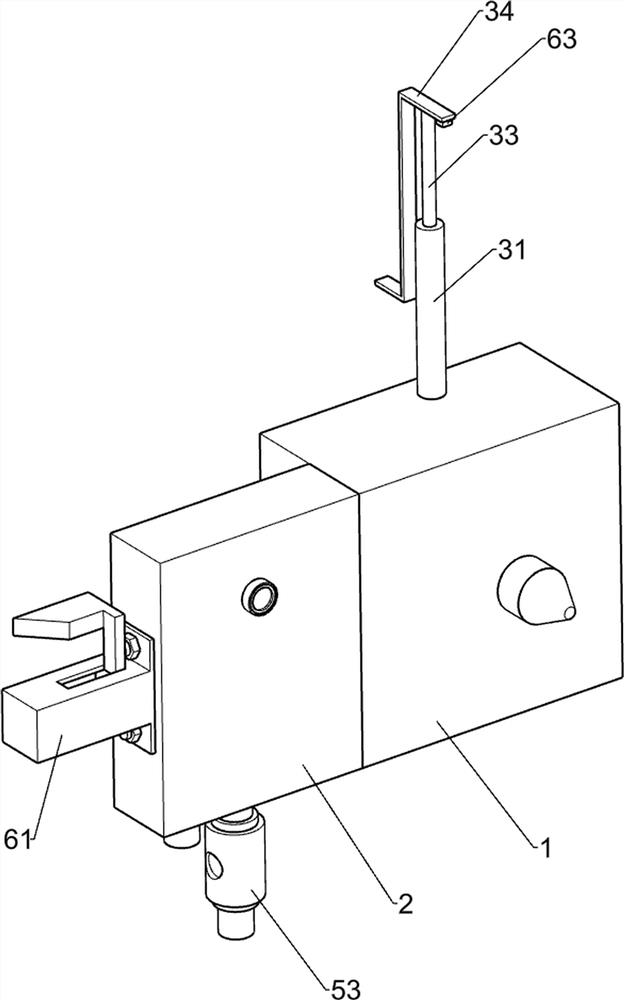

[0040] Embodiment: A new energy vehicle hydraulic valve plate assembly, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 and Figure 17 As shown, it includes a thick-layer valve plate 1, a thin-layer valve plate 2, a hydraulic booster pushing part 3, a shift adjustment part 4, a cooling lubricating oil diversion part 5 and a flow direction adjustment part 6, and the right side of the thick-layer valve plate 1 is fixed The thin-layer valve plate 2 is installed, the thick-layer valve plate 1 is provided with a hydraulic booster pushing part 3, the shift adjustment part 4 is set on the hydraulic booster pushing part 3, and the thin-layer valve plate 2 is provided with a cooling lubricating oil shunt Part 5, the cooling lubricating oil diversion part 5 is used to transport cooling lubricating oil, and the right sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com