Method for measuring surface shape of toric mirror

A measurement method and toric surface technology, applied in the direction of measuring devices, instruments, etc., can solve problems such as low precision, lack of rotational symmetry, and difficulty in surface shape inspection of curved mirrors, and achieve strong operability and high measurement accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

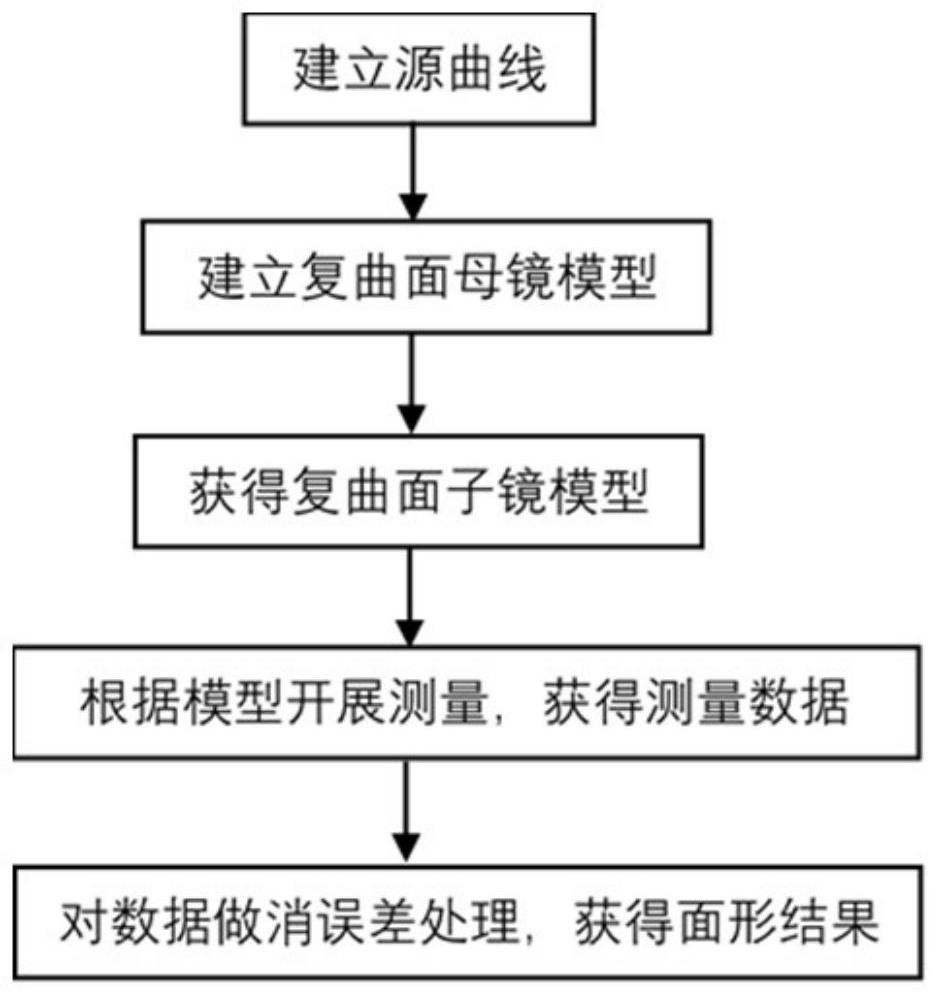

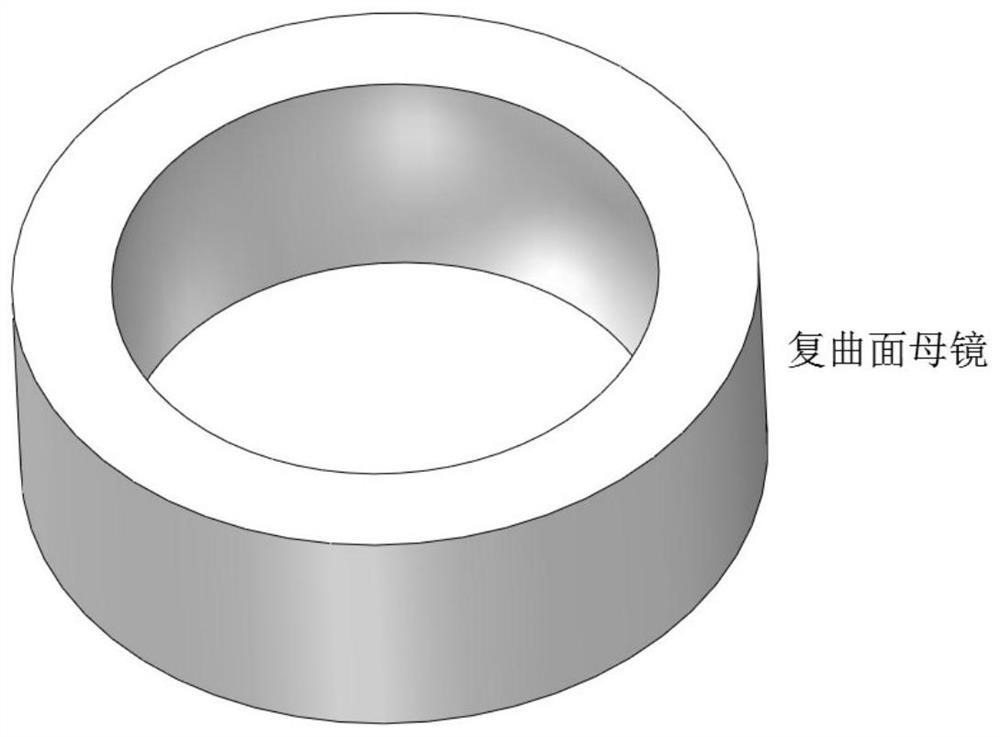

[0032] The toric surface mirror to be tested in the present invention is a part cut off from the toric surface master mirror formed by rotation. Therefore, in practice, it is necessary to first establish the CAD model of the toric surface mother mirror, and then select it from the toric surface master mirror through a fixed area. To obtain the CAD model of the toric sub-mirror. Such as figure 1 As shown, the toric surface mirror shape measuring method of the present invention specifically comprises the following steps:

[0033] (1) Construct the CAD model of the toric sub-mirror, specifically:

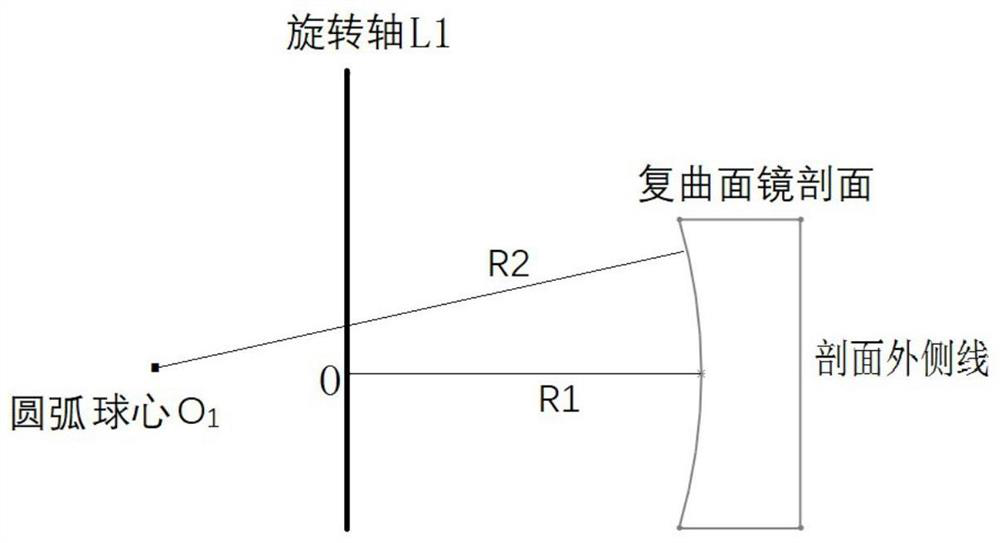

[0034] (1.1) Assume that the radius of curvature of the toric mirror in one direction is R1, and the radius of curvature perpendicular to this direction is R2; the geometric dimension of the solid toric mirror is H×W×d, and H represents the length of the toric mirror. W represents the width dimension of the toric mirror, and d represents the thickness of the geometric center of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com