Propylene polymerization quality on-line measurement system

A technology of propylene polymerization and measurement system, applied in measurement devices, chemical statistics, calculation models, etc., can solve the problems of low measurement accuracy, easy to be affected by human factors, etc., achieve a high level of confidence, and solve the problem of system mismatch , the effect of overcoming the measurement time lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

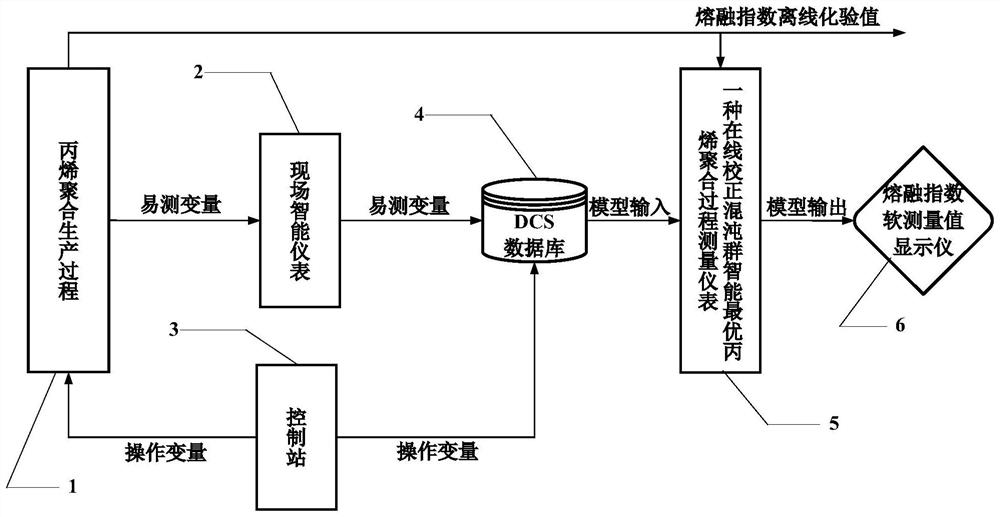

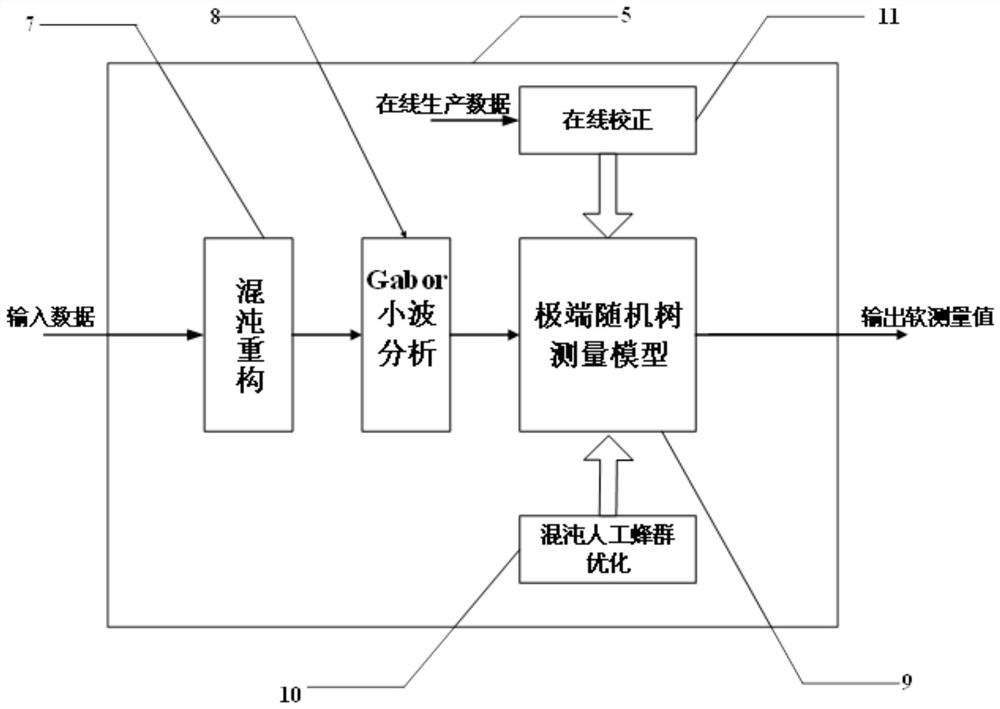

[0082] refer to figure 1 and figure 2 , figure 1 It is the overall architecture diagram of the quality online measurement system of the propylene polymerization process of the present invention; figure 2 It is a functional structural diagram of the online quality measurement system for propylene polymerization process of the present invention.

[0083] The polypropylene production quality inspection system of the present invention involves propylene polymerization production process 1, on-site intelligent instrument 2 for measuring easily measurable variables, control station 3 for measuring operating variables, DCS database 4 for storing data, and melting The index soft measurement value display instrument 6, the on-site intelligent instrument 2, the control station 3 are connected with the propylene polymerization production process 1, the on-site intelligent instrument 2, the control station 3 are connected with the DCS database 4, and the DCS database 4 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com