Novel lithium-sulfur battery and preparation method thereof

A lithium-sulfur battery, a new type of technology, applied in the manufacture of lithium batteries, electrolyte batteries, battery electrodes, etc., can solve the problems of low interface stability and large interface impedance, improve battery safety and cycle life, and inhibit lithium dendrites The generation and the effect of reducing the interface impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] On the other hand, the present invention also provides a preparation method of a novel lithium-sulfur battery, comprising the following steps:

[0036] Step S1: Making a solid electrolyte

[0037] Step S2: Making a liquid negative electrode

[0038] Step S3: Making a liquid positive electrode

[0039] Step S4: Making the current collector

[0040] Step S5: Press the liquid negative electrode on one side of the solid electrolyte sheet, drop the liquid positive electrode on the other side of the solid electrolyte sheet, cover the liquid positive electrode with the current collector, and assemble the button battery to form the new lithium-sulfur battery.

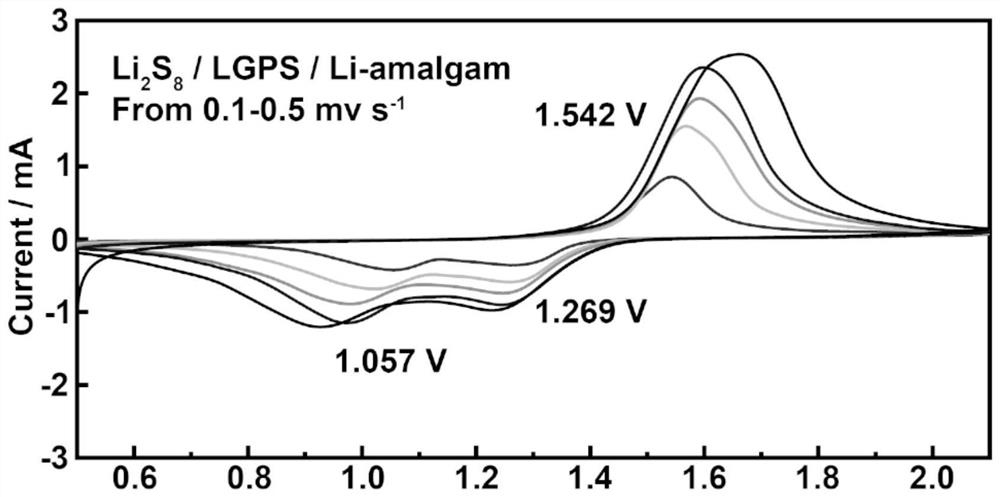

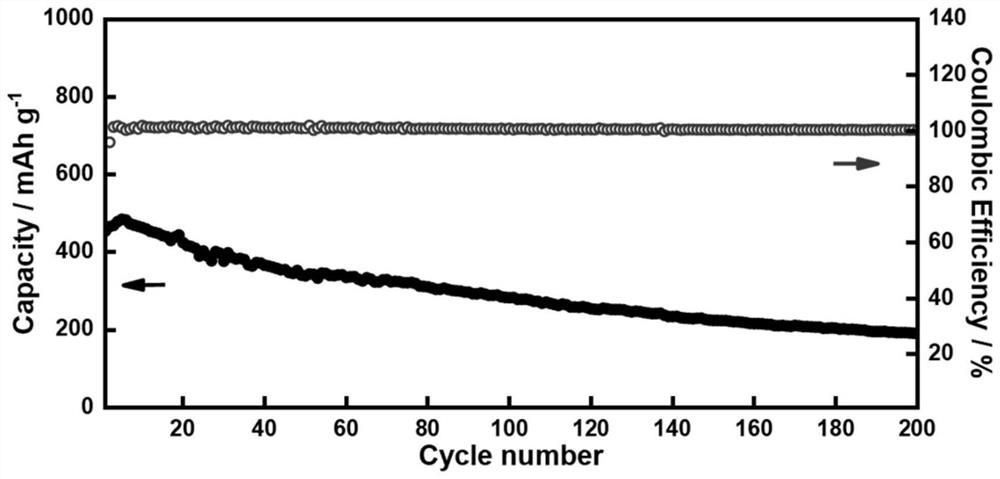

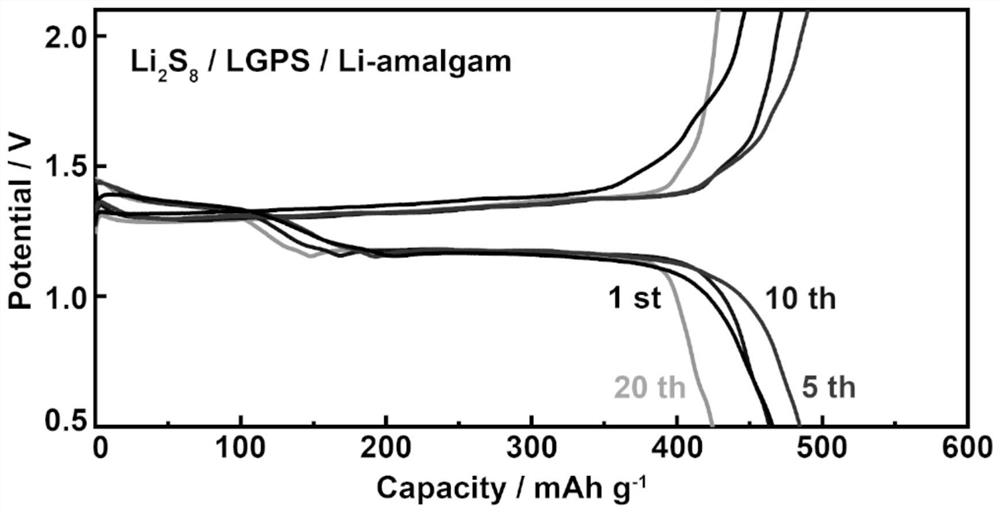

[0041] The invention solves the problem of low interface stability and large interface impedance of the electrode / solid electrolyte interface of the solid-state lithium-sulfur battery by using the liquid positive electrode and the negative electrode, and improves the capacity and cycle life of the solid-state lithium-s...

Embodiment 1

[0059] (1) Take 70 mg The powder was pressed with a mold with a diameter of 15 mm at a pressure of 80 MPa and held for 2 minutes to obtain a solid electrolyte sheet.

[0060] (2) Take 13 mg of lithium metal, remove the oxide film, cut it into pieces, add 1.487 g of metallic mercury, and let it stand for 48 hours to obtain 1.5 g of liquid lithium amalgam. Put the base material into a mold with a diameter of 15 mm and add liquid lithium amalgam, press it into a tablet at a pressure of 200 MPa, hold the pressure for 3 minutes, and obtain a liquid negative electrode.

[0061] (3) Take 114.8 mg lithium sulfide, 560 mg elemental sulfur, add 10 ml 1 M LiTFSI (DME:DOL=1:1, with 1 wt% LiNO 3 ), ultrasonically dispersed for 30 minutes, and then magnetically stirred for 48 hours to obtain a liquid positive electrode.

[0062] (4) Take 90 mg of conductive graphene and 10 mg of PVDF, add 2 ml of NMP, and stir magnetically for 24 hours. The resulting slurry is coated on aluminum foil, dr...

Embodiment 2

[0065] (1) Take 100 mg The powder was pressed with a mold with a diameter of 15 mm, the pressure was 100 MPa, and the pressure was maintained for 3 minutes to obtain a solid electrolyte sheet.

[0066] (2) Take 26 mg of lithium metal, remove the oxide film, cut it into pieces, add 2.974 g of metallic mercury, and let it stand for 48 hours to obtain 3 g of liquid lithium amalgam. Put the base material into a mold with a diameter of 15 mm and add liquid lithium amalgam, press it into a tablet at a pressure of 300 MPa, and hold the pressure for 5 minutes to obtain a liquid negative electrode.

[0067] (3) Take 229.6 mg lithium sulfide, 1.12 g elemental sulfur, add 20 ml 1 M LiTFSI (DME:DOL=1:1, with 1 wt% LiNO 3 ), ultrasonically dispersed for 30 minutes, and then magnetically stirred for 48 hours to obtain a liquid positive electrode.

[0068] (4) Take 180 mg of conductive graphene and 20 mg of PVDF, add 4 ml of NMP, and stir magnetically for 24 hours. The resulting slurry is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com