Four-stage motor

A brush and winding technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of not covering the enameled wire, low energy consumption, many turns, etc., to achieve stable driving force, simple structure, and long life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

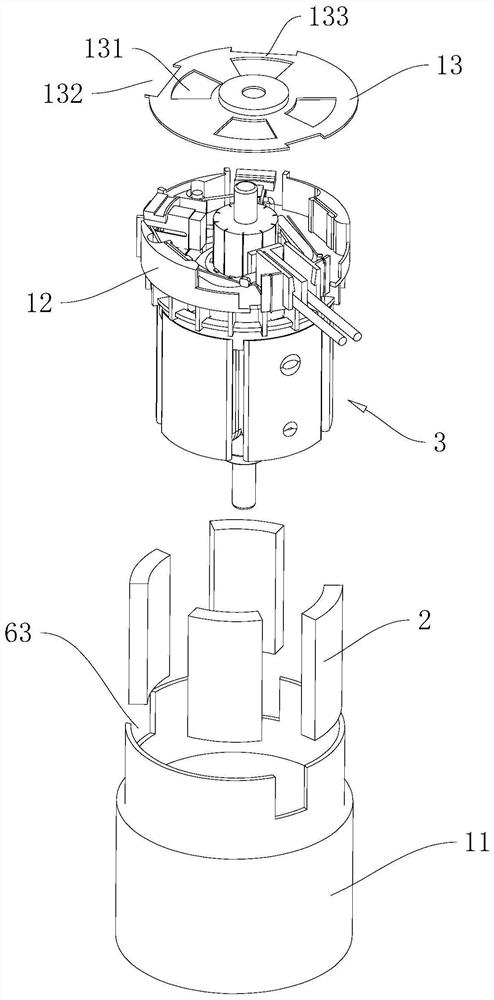

[0036] The following is attached Figure 1-7 The application is described in further detail.

[0037] The embodiment of the present application discloses a four-stage motor.

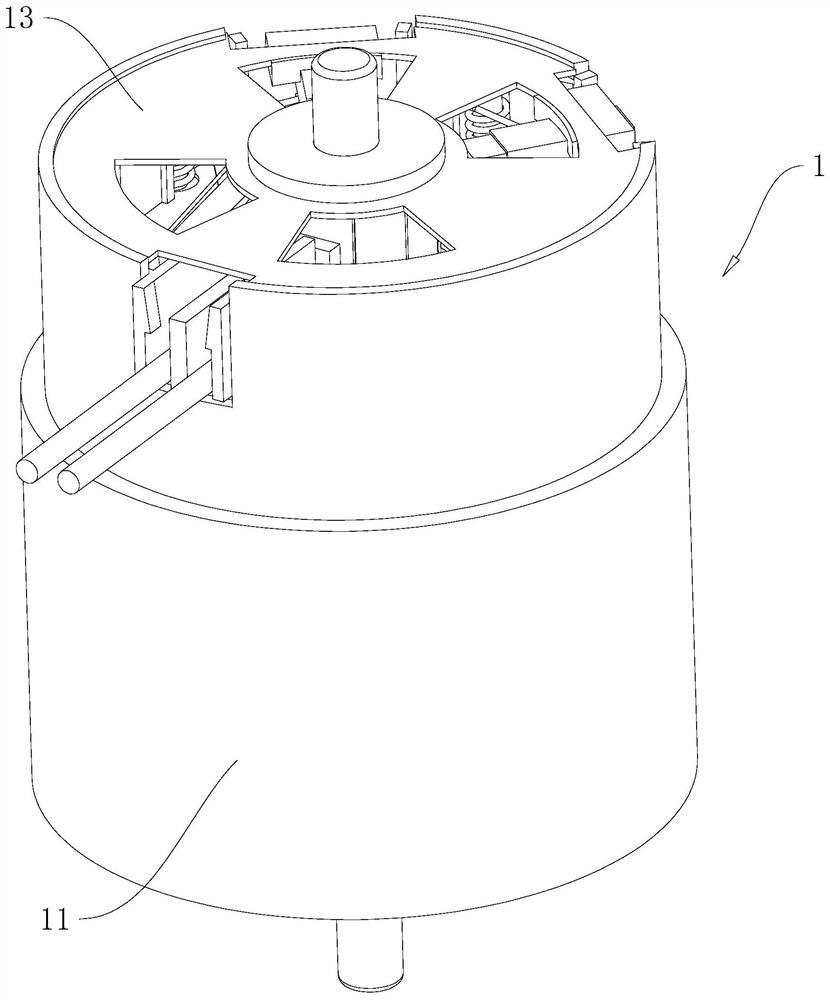

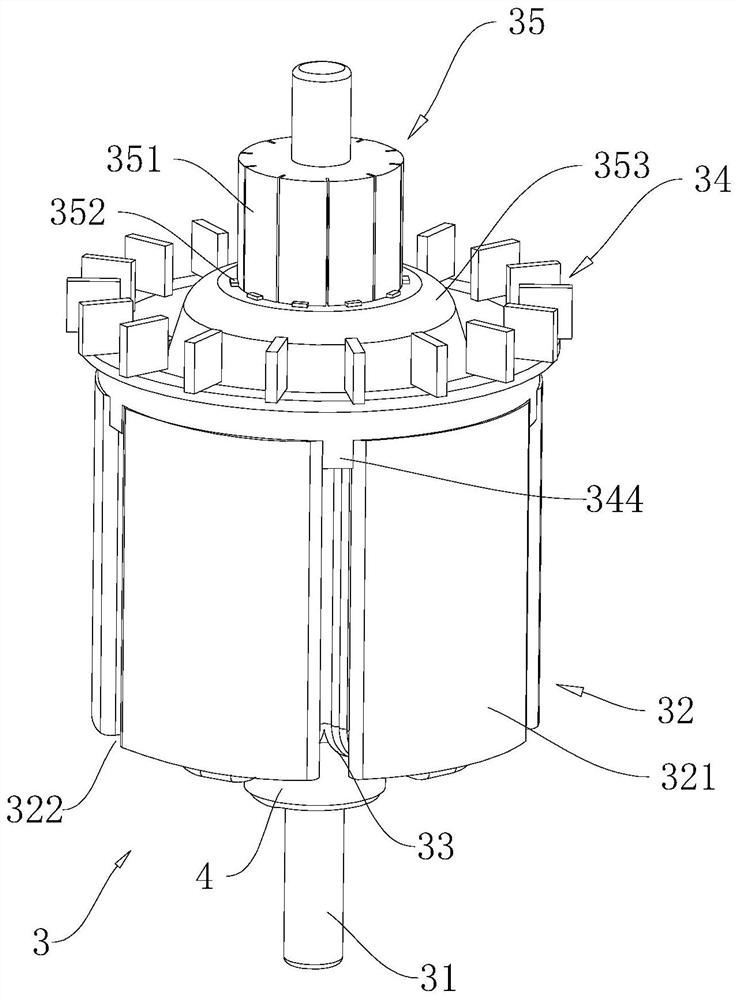

[0038] refer to figure 1 and figure 2 , a four-stage motor, including a housing 1, a magnetic pole 2 and a rotor 3, the housing 1 includes a housing 11 and an end cover 12, the housing 11 is a cylindrical housing 11 with one end open, and one end of the opening of the housing 11 is closed by the end cover 12 , the magnetic poles 2 are installed in the housing 1, and there are two pairs of magnetic poles 2, each pair of magnetic poles 2 includes N-level and S-level, and two pairs of four magnetic poles 2 are alternately arranged on the inner wall of the housing 11 to form N-level, S-level, N-level, The alternate arrangement of S levels forms a magnetic field between adjacent magnetic poles 2, and along the circumferential direction of the casing 1, the four magnetic fields are alternately opposite.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com