Solid beverage and preparation method thereof

A solid beverage and raw material technology, applied in the field of food processing, can solve the problems of complicated process, expensive equipment and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

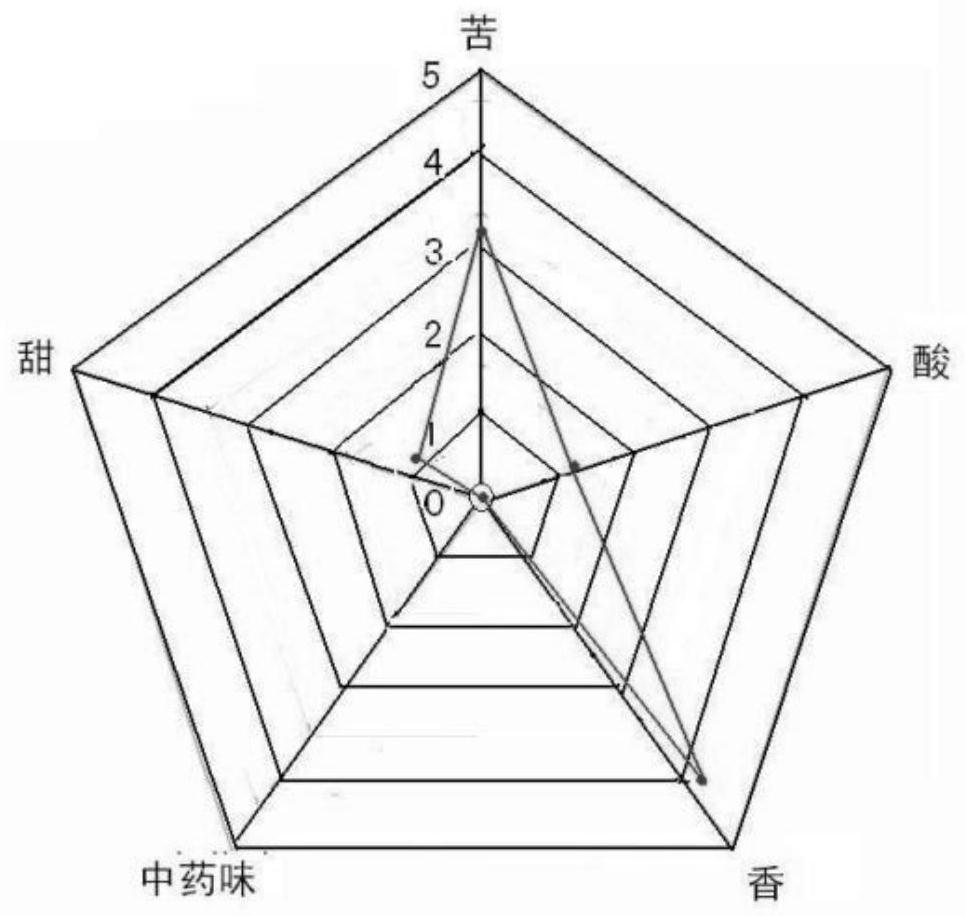

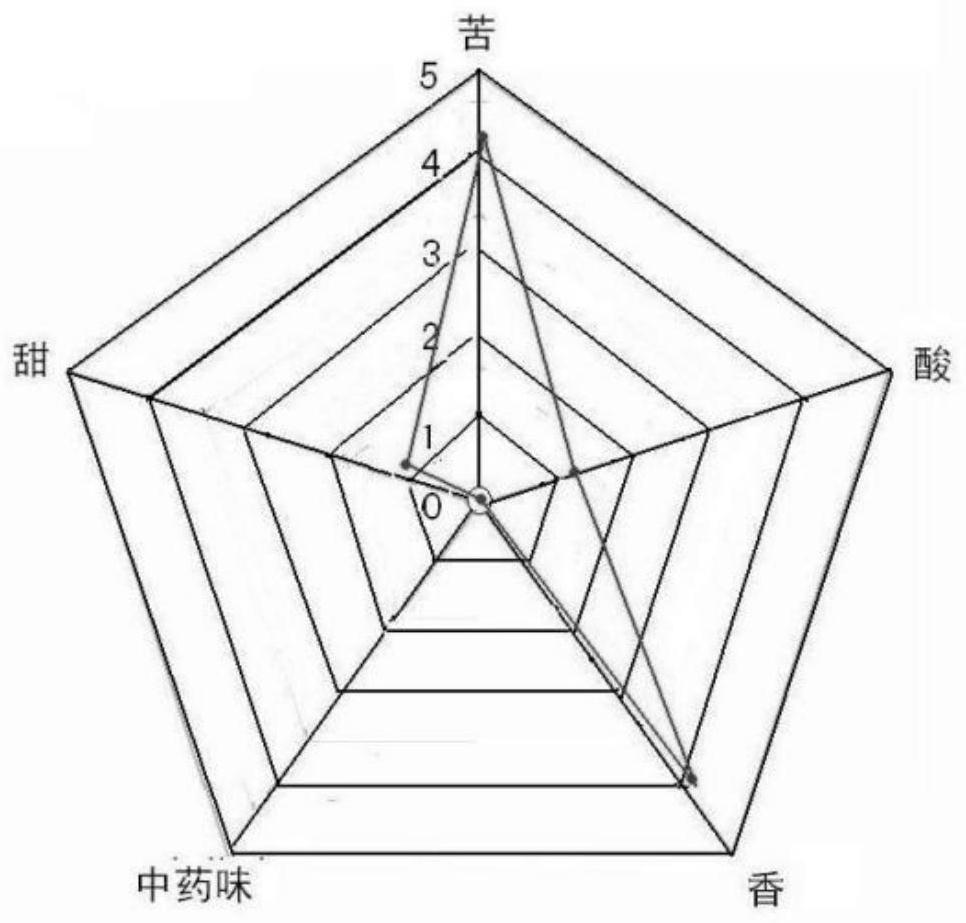

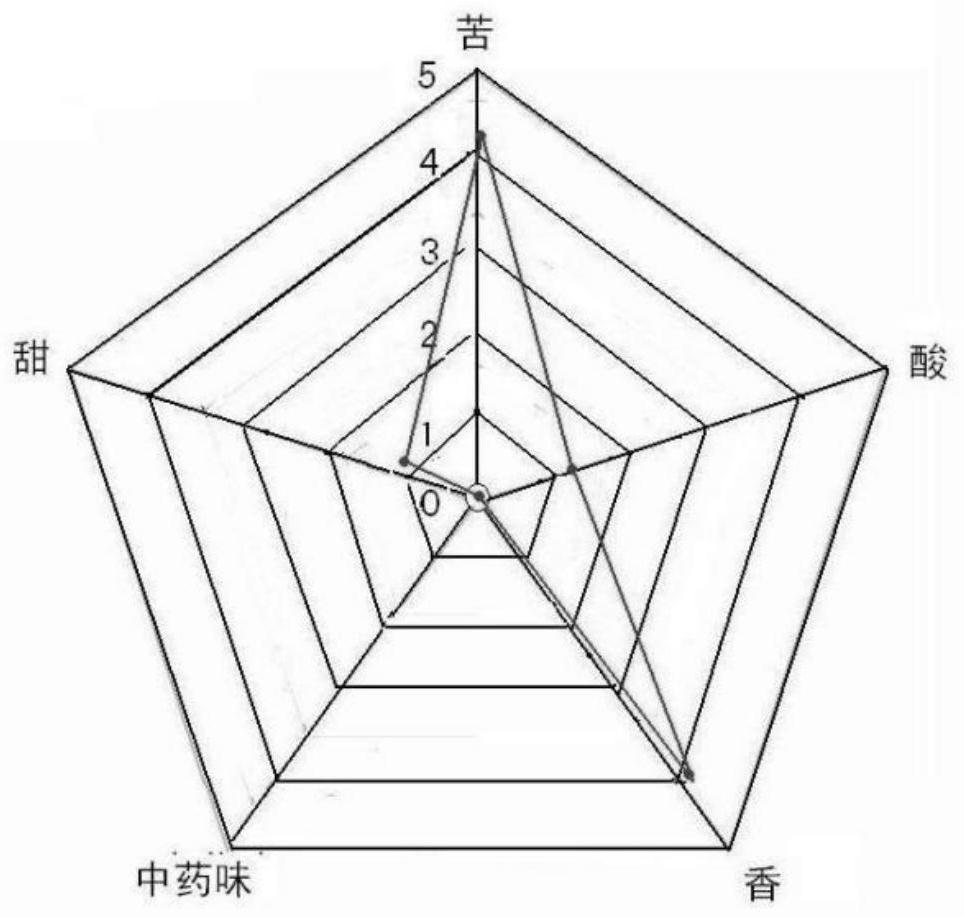

Image

Examples

Embodiment 1

[0065] 6 parts of dried dandelion root and 4 parts of dried dandelion leaf.

[0066] S11, cutting dandelion roots and dandelion leaves to a length of 2-3cm;

[0067] S12. Mix the dandelion root and dandelion leaf evenly, place in a fermentation container, and ferment naturally at a temperature of 18° C. for 72 hours under sealed conditions;

[0068] S13, placing the naturally fermented substrate in a multi-layer grille oven, with the material height of each layer being 6 cm, and performing a Maillard reaction at 80° C. for 8 hours;

[0069] S14, pulverizing the dandelion roots and dandelion leaves after the Maillard reaction to a particle size of 0.15mm;

[0070] S15. Carry out extrusion and puffing after crushing, control the puffing temperature to 118°C, and the twin-screw speed to 230r / min, until the moisture content of the material is 23%;

[0071] S16. Bake the extruded dandelion roots and dandelion leaves at 180° C. for 20 minutes;

[0072]S17. The roasted dandelion r...

Embodiment 2

[0074] 6 parts of fresh dandelion root, 4 parts of fresh dandelion leaf.

[0075] S21, cutting the dandelion root and dandelion leaf to a length of 2-3cm;

[0076] S22. Mix the dandelion roots and dandelion leaves evenly, place them in a fermentation container, and ferment naturally at a temperature of 32° C. for 24 hours under sealed conditions;

[0077] S23. Place the naturally fermented substrate in a multi-layer grille oven with a material height of 10 cm in each layer, and carry out Maillard reaction at 80° C. for 10 hours;

[0078] S24, pulverizing the dandelion root and dandelion leaves after the Maillard reaction to a particle size of 0.18mm;

[0079] S25. Carry out extrusion and puffing after pulverization, control the puffing temperature to 128°C, and the rotation speed to 230r / min until the water content of the material is 23%;

[0080] S26. Bake the extruded dandelion roots and dandelion leaves at 180° C. for 20 minutes;

[0081] S27. Roll granulate the baked da...

Embodiment 3

[0083] 10 parts of semi-dried dandelion root.

[0084] S31, cutting the dandelion root to a length of 2-3cm;

[0085] S32, placing the dandelion root in a fermentation container, and fermenting naturally at a temperature of 28° C. for 48 hours under sealed conditions;

[0086] S33, placing the naturally fermented substrate in a multi-layer grille oven, with each layer of materials having a height of 8 cm, and performing a Maillard reaction at 70° C. for 12 hours;

[0087] S34, pulverizing the dandelion root after the Maillard reaction to a particle size of 0.18mm;

[0088] S35. Carry out extrusion and puffing after pulverization, control the puffing temperature to 138°C, and the rotation speed to 230r / min until the moisture content of the material is 22%;

[0089] S36. Bake the extruded and expanded dandelion root at 220° C. for 8 minutes;

[0090] S37. The roasted dandelion root is dry-rolled and granulated, and passed through a 20-mesh sieve to obtain dandelion root coffe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com