Preparation method of copper mesh integrated Cu2O@FeO nano array

A nano-array and copper mesh technology, applied in the field of photocatalysts, can solve the problems of poor stability of photocatalysts, and achieve the effects of abundant reserves, convenient and simple product processing, and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

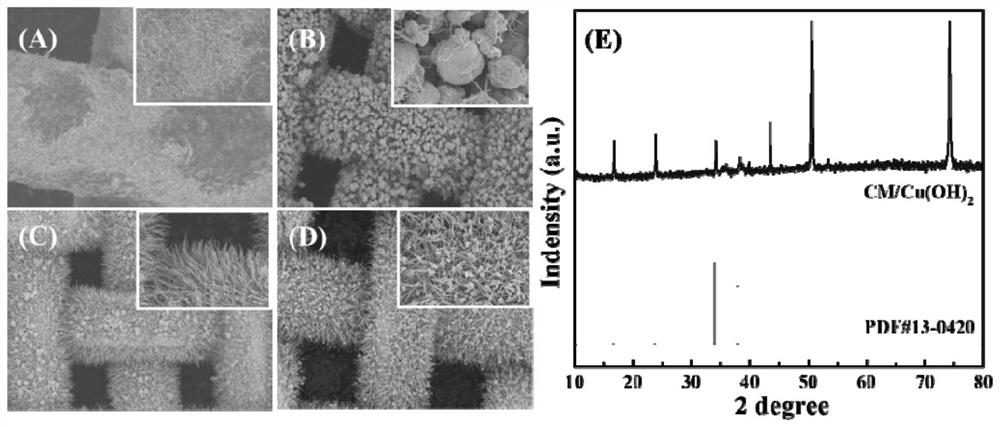

[0075] (1) In situ preparation of Cu(OH) on copper mesh substrate 2

[0076] In the first step, prepare 1mol / L, 2mol / L, 2.5mol / L and 3mol / L sodium hydroxide solutions respectively, dissolve 0.54g of ammonium persulfate in 20mL of sodium hydroxide solution, and sonicate for 20 minutes;

[0077] In the second step, the copper mesh treated with 1mol / L hydrochloric acid ultrasonic treatment was added to the solution prepared in the first step, and left to stand for 40 minutes, and the surface of the copper mesh was observed to appear dark blue;

[0078] In the third step, the copper mesh was taken out and washed repeatedly with deionized water to remove impurities, and then the product was dried in a vacuum oven at 60°C for 24 hours, and then sealed and stored in an inert atmosphere after taking it out.

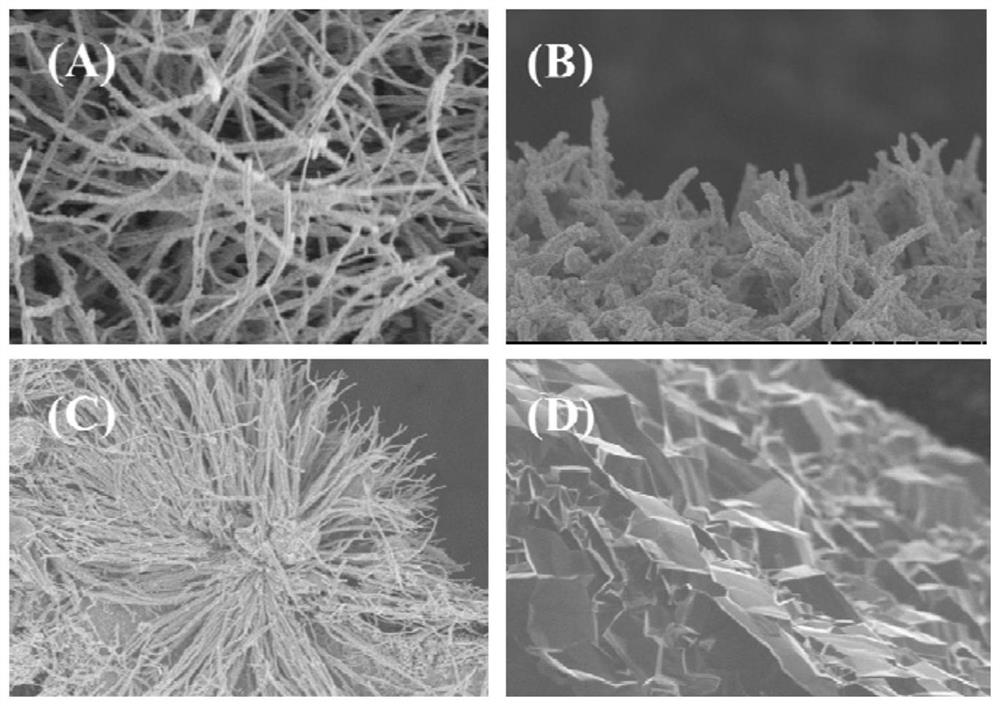

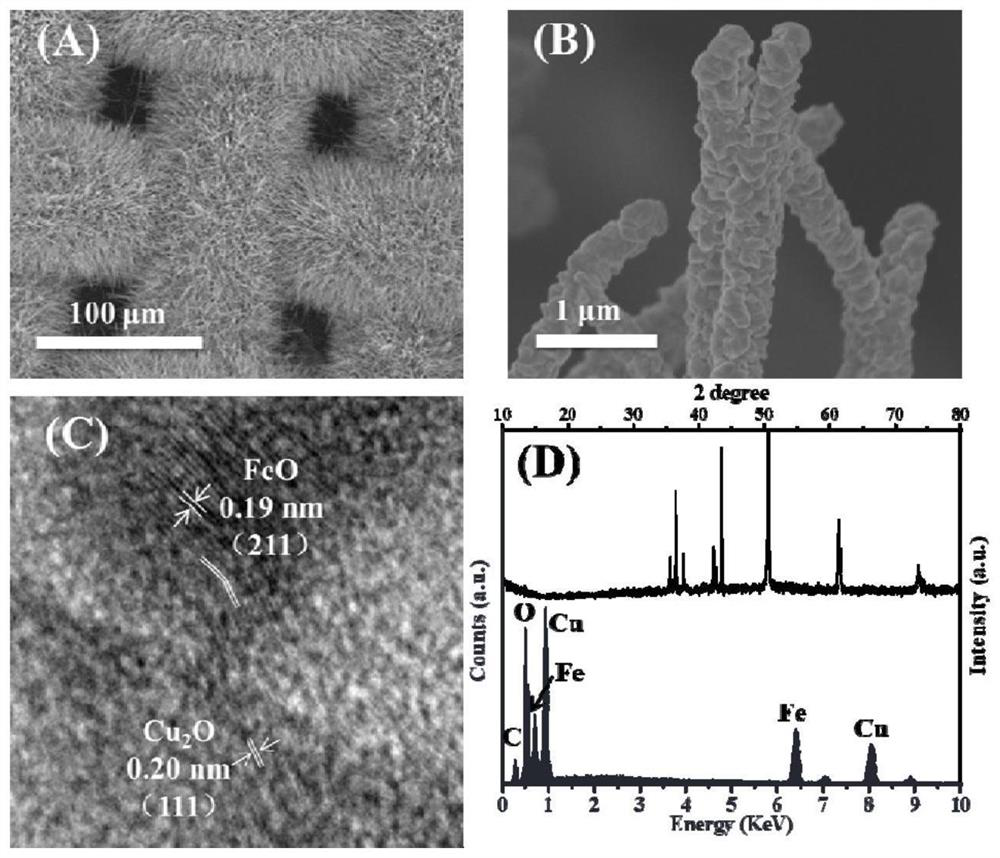

[0079] (2) In situ preparation of Cu(OH) on copper mesh substrate 2 @Fe(OH) 3 Precursor

[0080] In the first step, Cu(OH) was prepared in situ on the copper mesh substrate p...

Embodiment 2

[0090] (1) In situ preparation of Cu(OH) on copper mesh substrate 2

[0091] The first step is to prepare 2.5mol / L sodium hydroxide solution, dissolve 0.54g ammonium persulfate in 20mL sodium hydroxide solution, and ultrasonicate for 20min;

[0092] In the second step, the copper mesh treated with 1mol / L hydrochloric acid ultrasonic treatment was added to the solution prepared in the first step, and left to stand for 40 minutes, and the surface of the copper mesh was observed to appear dark blue;

[0093] In the third step, the copper mesh was taken out and washed repeatedly with deionized water to remove impurities, and then the product was dried in a vacuum oven at 60°C for 24 hours, and then sealed and stored in an inert atmosphere after taking it out.

[0094] (2) In situ preparation of Cu(OH) on copper mesh substrate 2 @Fe(OH) 3 Precursor

[0095] In the first step, Cu(OH) was prepared in situ on the copper mesh substrate prepared above. 2Place in pre-prepared 0.5mmo...

Embodiment 3

[0105] (1) In situ preparation of Cu(OH) on copper mesh substrate 2

[0106] The first step is to prepare 2.5mol / L sodium hydroxide solution respectively, dissolve 0.54g ammonium persulfate in 20mL sodium hydroxide solution, and ultrasonicate for 20min;

[0107] In the second step, the copper mesh treated with 1mol / L hydrochloric acid ultrasonic treatment was added to the solution prepared in the first step, and left to stand for 40 minutes, and the surface of the copper mesh was observed to appear dark blue;

[0108] In the third step, the copper mesh was taken out and washed repeatedly with deionized water to remove impurities, and then the product was dried in a vacuum oven at 60°C for 24 hours, and then sealed and stored in an inert atmosphere after taking it out.

[0109] (2) In situ preparation of Cu(OH) on copper mesh substrate 2 @Fe(OH) 3 Precursor

[0110] In the first step, Cu(OH) was prepared in situ on the copper mesh substrate prepared above. 2 Place in pre-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com