Multi-layer coated co-extrusion profile and production method thereof

A multi-layer coating and production method technology, applied in the direction of layered products, metal layered products, chemical instruments and methods, etc., can solve the problems of aggravating the wear of wood-plastic materials, lack of surface elasticity, and affecting the aesthetics, and achieve enhanced Surface properties, overall quality improvement, effects of differences in cushioning material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

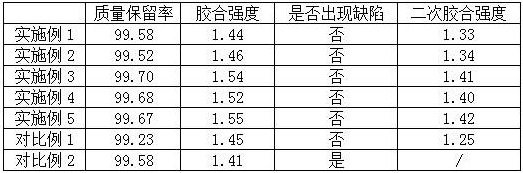

Examples

Embodiment 1

[0037] S1. Provide a rigid core material;

[0038] S2. Preheat the rigid core material, and then introduce it into the core material channel of the co-extrusion die; at the same time, melt and extrude the first adhesive through the first extruder into the first adhesive of the co-extrusion die In the flow channel, the first adhesive is coated around the rigid core material to form a rubber-coated core material; then the polyolefin wood-plastic material is melted and plasticized by the second extruder and then extruded into the co-extrusion mold In the middle layer flow channel, the polyolefin wood-plastic material is coated on the rubber-coated core material to form an intermediate layer to obtain the first coated core material; then the second adhesive is melt-extruded through the third extruder into the second adhesive runner of the co-extrusion die, so that the second adhesive is coated around the first coating core material to form a second rubber coating core material; th...

Embodiment 2

[0045] S1. Provide a rigid core material;

[0046] S2. Preheat the rigid core material, and then introduce it into the core material channel of the co-extrusion die; at the same time, melt and extrude the first adhesive through the first extruder into the first adhesive of the co-extrusion die In the flow channel, the first adhesive is coated around the rigid core material to form a rubber-coated core material; then the polyolefin wood-plastic material is melted and plasticized by the second extruder and then extruded into the co-extrusion mold In the middle layer flow channel, the polyolefin wood-plastic material is coated on the rubber-coated core material to form an intermediate layer to obtain the first coated core material; then the second adhesive is melt-extruded through the third extruder into the second adhesive runner of the co-extrusion die, so that the second adhesive is coated around the first coating core material to form a second rubber coating core material; th...

Embodiment 3

[0053] S1. Provide a rigid core material;

[0054] S2. Preheat the rigid core material, and then introduce it into the core material channel of the co-extrusion die; at the same time, melt and extrude the first adhesive through the first extruder into the first adhesive of the co-extrusion die In the flow channel, the first adhesive is coated around the rigid core material to form a rubber-coated core material; then the polyolefin wood-plastic material is melted and plasticized by the second extruder and then extruded into the co-extrusion mold In the middle layer flow channel, the polyolefin wood-plastic material is coated on the rubber-coated core material to form an intermediate layer to obtain the first coated core material; then the second adhesive is melt-extruded through the third extruder into the second adhesive runner of the co-extrusion die, so that the second adhesive is coated around the first coating core material to form a second rubber coating core material; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com