Ground source heat comprehensive utilization system and heat supply method

A technology of ground source heat and heat exchange system, which is applied in the comprehensive utilization system of ground source heat and the field of heat supply, can solve the problems of long cycle, waste of heat energy, and inability of workers to work normally, so as to reduce energy waste, maintain comfort, and realize The effect of energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

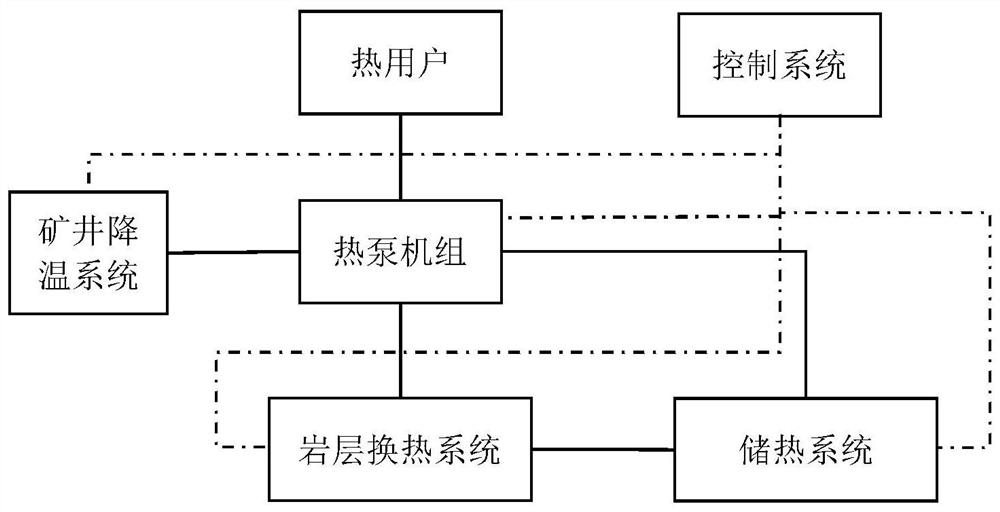

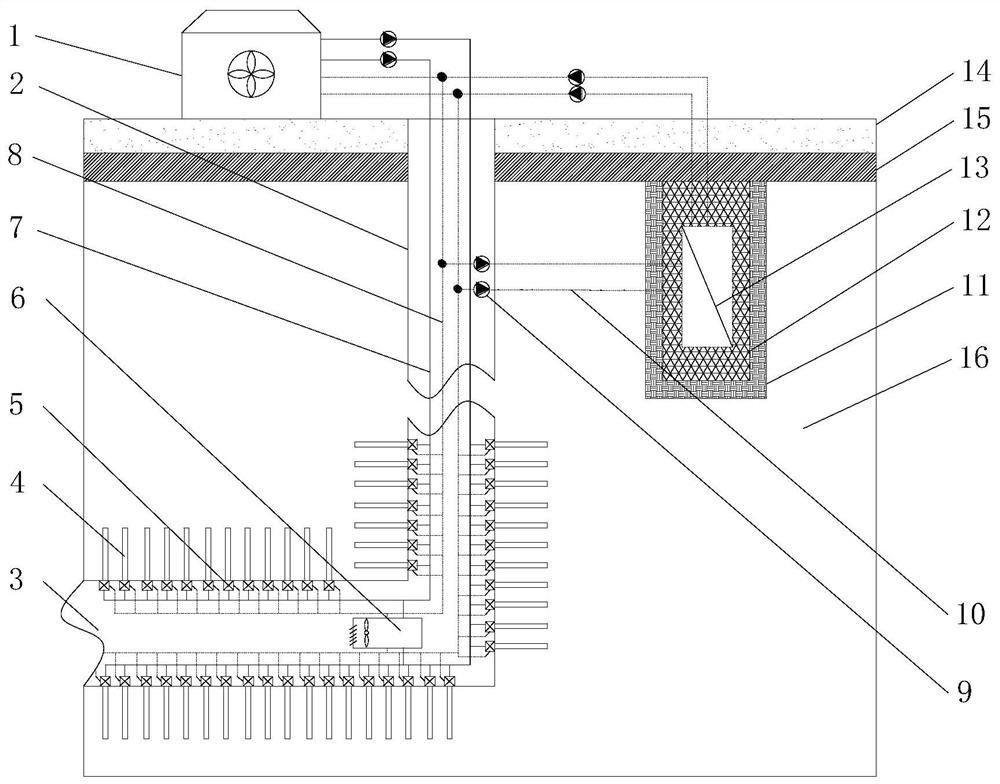

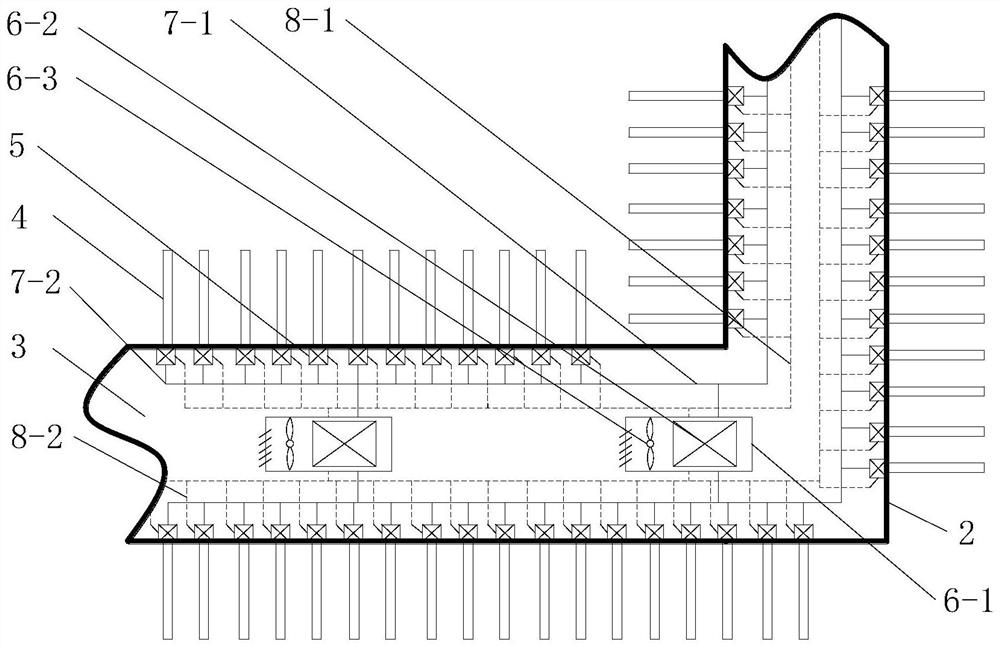

[0043] study figure 1 A ground source heat comprehensive utilization system includes a heat pump unit, a rock formation heat exchange system, a heat storage system, a mine cooling system, a control system, and a heat user. Among them, the evaporation unit of the heat pump unit is connected to the heat exchange system of the rock formation through the first pipeline system, the heat exchange system of the rock formation is connected to the heat storage system through the second pipeline system, and the heat storage system is connected to the evaporation unit of the heat pump unit through the third pipeline system. The input end of the unit is connected, the output end of the evaporation unit of the heat pump unit is also connected with the mine cooling system through the fourth pipeline, and the control system is respectively connected with the heat pump unit, the rock formation heat exchange system, the heat storage The system can control the status of heat pump units, rock fo...

Embodiment 2

[0056] The control system is connected with the touch-screen operation panel, and the technician can set the first adjustment preset temperature corresponding to the first adjustment temperature and the second adjustment preset temperature corresponding to the second adjustment temperature through the touch-screen operation panel. A third regulated preset temperature corresponding to the third regulated temperature.

[0057] The preset temperature range of the first adjustment is 40-50°, the preset temperature range of the second adjustment is 40-45°, and the preset temperature range of the third adjustment is 5-13°.

[0058] Based on the ground source heat comprehensive utilization system described in Embodiment 1, it also includes the following control method:

[0059] Step SS1: When the first regulated temperature detected by the first temperature sensor is lower than the minimum value of the first regulated preset temperature range, only the first three-way valve is contro...

Embodiment 3

[0063] Based on the ground source heat comprehensive utilization system described in Embodiment 2, it also includes the following control method:

[0064]Step SS4: When the first regulated temperature detected by the first temperature sensor is within the first regulated preset temperature range, only the first three-way valve is controlled and its straight-through pipeline is opened, so that the water in the return water branch pipe 8-2 flows through the first regulated temperature range. A pipeline system returns to the heat pump unit 1, and reduces the opening degree of the first regulating valve;

[0065] Step SS5: When the first regulated temperature detected by the first temperature sensor is within the first regulated preset temperature range, control the first three-way valve to open both the bypass pipeline and the straight-through pipeline;

[0066] Step SS6: On the basis of step SS5, when the second adjustment temperature detected by the second temperature sensor is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com