High-resolution defect nondestructive testing method based on combination of ultrasonic plane wave imaging and time reversal operator

A time-reversal, non-destructive testing technology, applied in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measuring devices, which can solve problems such as low detection accuracy and slow non-destructive testing speed. Achieve the effect of improving signal-to-noise ratio, fast defect, and improving detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

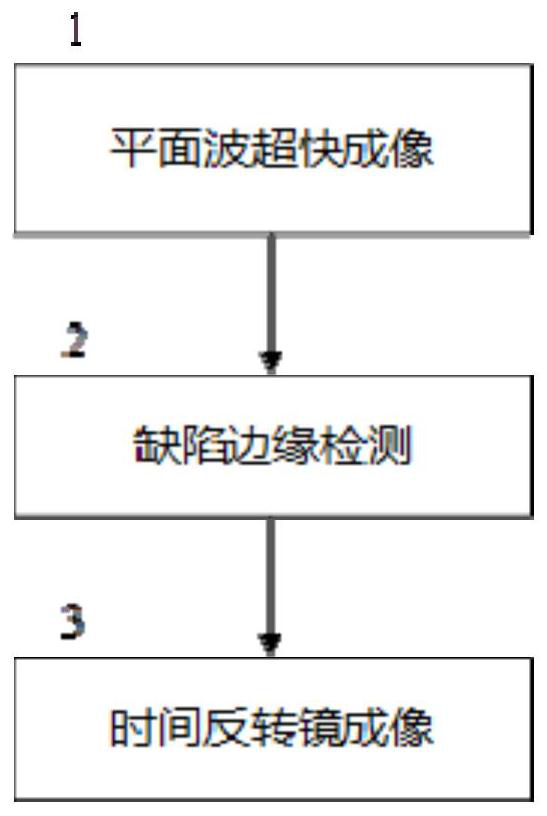

[0038] according to Figure 1 to Figure 3 As shown, the present invention provides a high-resolution defect nondestructive testing method based on the combination of ultrasonic plane wave imaging and time-reversal operator, and the specific steps are as follows:

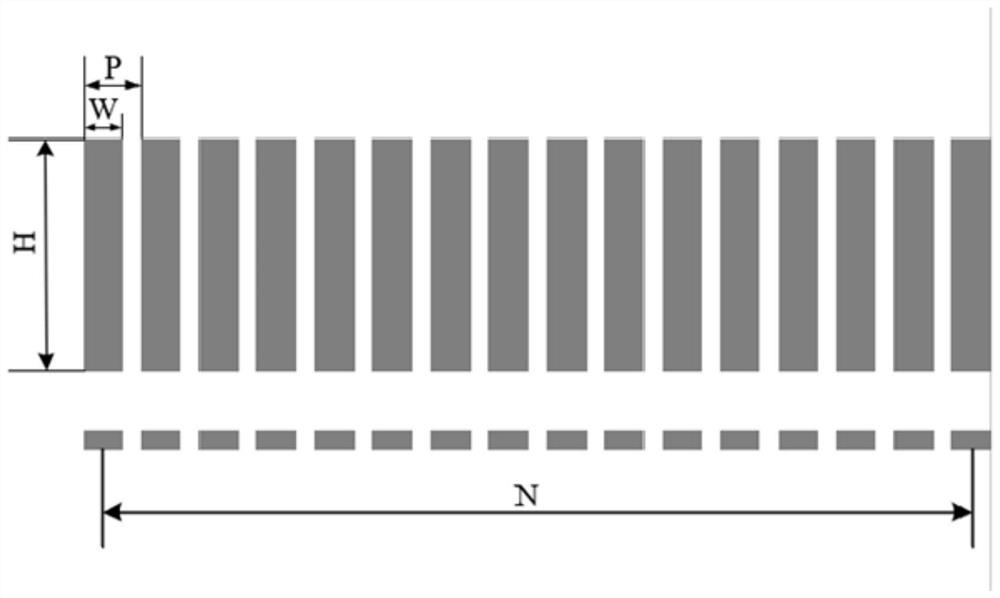

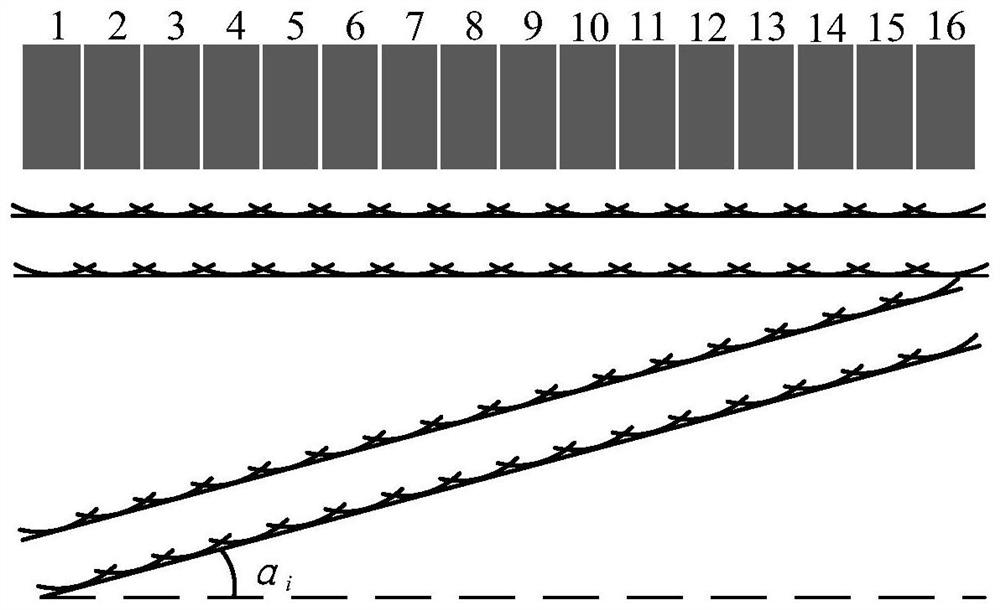

[0039] Step 1, transmit a group of plane waves to the workpiece to be measured through the ultrasonic linear phased array, where the deflection angle of each plane wave is α i satisfy:

[0040]

[0041] Where λ is the wavelength of the ultrasonic wave, and p is the distance between adjacent elements of the ultrasonic phased array.

[0042] Then, the reflected echo data of each plane wave is collected by ultrasonic phased array, and the echo data is filtered in time domain to filter out the random noise in the signal. Set the scanning plane, calculate the distance between the scanning pixels and each array element of the phased array, and use the ultrasonic propagation sound velocity in the workpiece to calculate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com