Polyphosphazene, and preparation method and application thereof

A technology of polyphosphazene and polydichlorophosphazene, which is applied in the field of flame retardants, can solve the problems of unsatisfactory flame retardant effect, and achieve the effect of excellent flame retardant effect, good compatibility and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

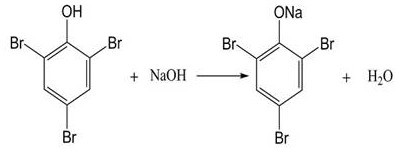

[0032] The preparation method of polyphosphazene provided by the invention comprises:

[0033] S1. Dissolve 2,4,6-tribromophenol in a solvent, add sodium hydroxide, heat up to 30-80°C, react for 0.5-4 hours, and obtain reactant a after the reaction is completed;

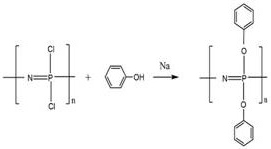

[0034] S2. Dissolving linear polydichlorophosphazene in a solvent to obtain reactant b;

[0035] S3. Slowly add reactant b to reactant a dropwise to react, the reaction temperature is 60-90°C, and the reaction time is 3-20 hours;

[0036] S4. After the reaction, the solvent is recovered, washed with water, filtered and dried to obtain polyphosphazene.

[0037] Further, the mass ratio of linear polydichlorophosphazene to 2,4,6-tribromophenol is 1:6-8.5, for example, 1:6, 1:6.8, 1:7, 1:7.5, 1: 8, 1:8.3, 1:8.5, etc.

[0038] Further, the reaction temperature in step S3 is 80-85°C, and the reaction time is 5-8 hours. For example, the reaction temperature can be 80°C, 81°C, 84°C, 85°C, etc., and the reaction time c...

Embodiment 1

[0049] A preparation method of polyphosphazene, comprising:

[0050] S1. In a reaction device equipped with a magnetic stirrer, a thermometer, and a reflux condenser, add 500 mL of tetrahydrofuran and 25.00 g (0.075 mol) of 2,4,6-tribromophenol, and fully stir to dissolve it under nitrogen protection; then add hydrogen Sodium oxide 7.00g (0.175mol), heated up to 70°C, reacted for 3h, and obtained reactant a after the reaction;

[0051] S2. Dissolve 3.00 g of linear polydichlorophosphazene in 200 mL of tetrahydrofuran under nitrogen protection conditions to obtain reactant b;

[0052] S3. Slowly add reactant b to reactant a dropwise under the condition of nitrogen protection, control the reaction temperature at 85°C, and react for 6 hours;

[0053] S4. After the reaction was completed, the solvent was recovered, washed with water, filtered, and dried to obtain 13.8 g of polyphosphazene with a yield of 75.7%.

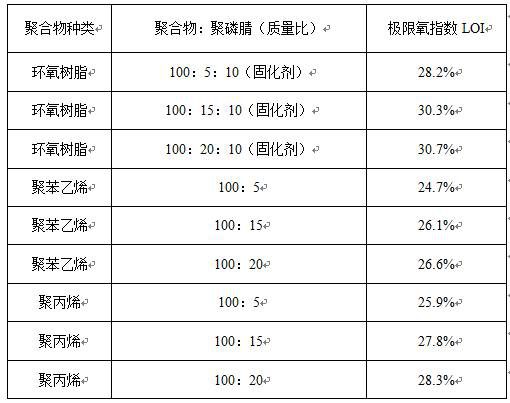

[0054] Test has added the limiting oxygen index LOI of the polym...

Embodiment 2

[0058] A preparation method of polyphosphazene, comprising:

[0059] S1. In a reaction device equipped with a magnetic stirrer, a thermometer, and a reflux condenser, add 300 mL of tetrahydrofuran and 25.00 g (0.075 mol) of 2,4,6-tribromophenol, and fully stir to dissolve it under nitrogen protection; then add hydrogen Sodium oxide 6.00g (0.150mol), heated up to 30°C, reacted for 4h, and obtained reactant a after the reaction;

[0060] S2. Dissolve 3.30 g of linear polydichlorophosphazene in 135 mL of tetrahydrofuran under nitrogen protection conditions to obtain reactant b;

[0061] S3. Slowly add reactant b to reactant a dropwise under the condition of nitrogen protection, control the reaction temperature at 80°C, and react for 5 hours;

[0062] S4. After the reaction was completed, the solvent was recovered, washed with water, filtered and dried to obtain 14.9 g of polyphosphazene with a yield of 74.3%.

[0063] The polyphosphazene prepared in this example was mixed a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com