A kind of blast furnace oxygen-enriched cyclic combustion method and system for ironmaking

A cycle combustion and blast furnace technology, applied in blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems of stable oxygen concentration in pure oxygen smelting iron, carbon capture in iron smelting process, etc., and achieve the effect of reducing carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

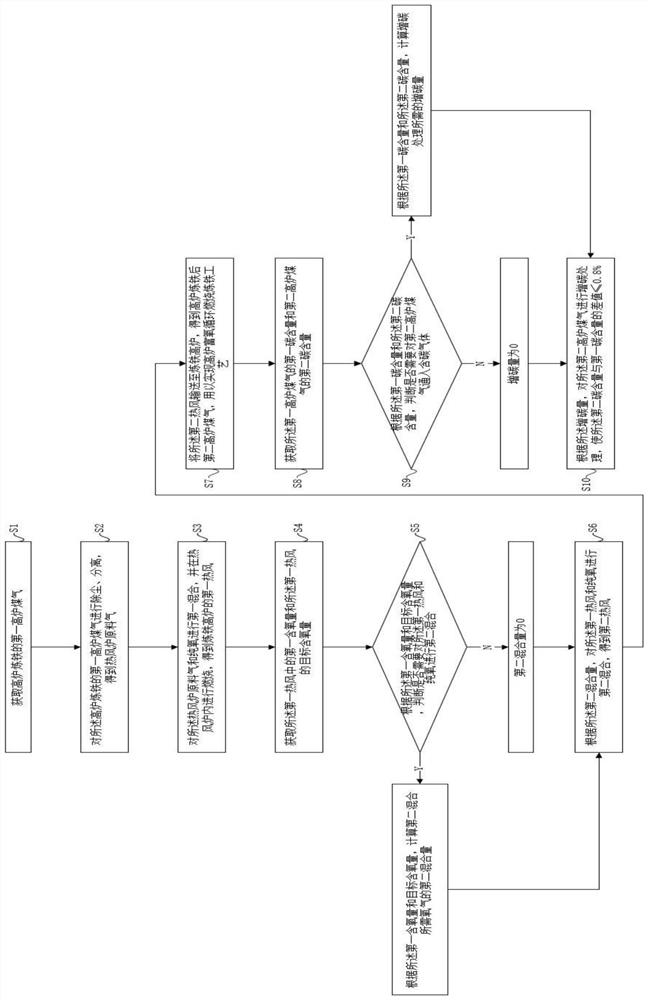

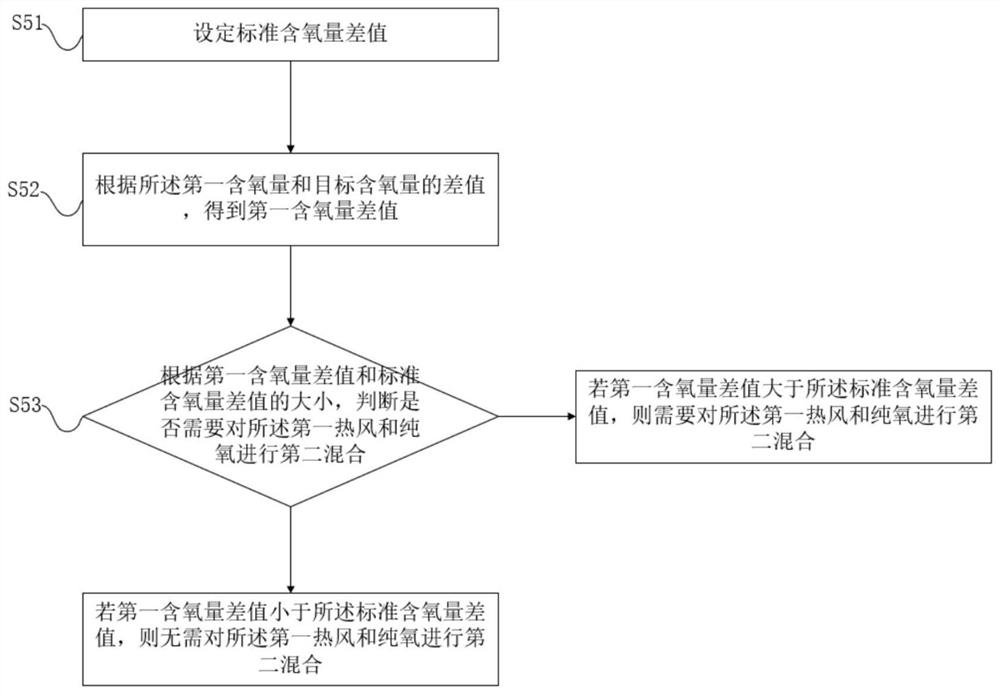

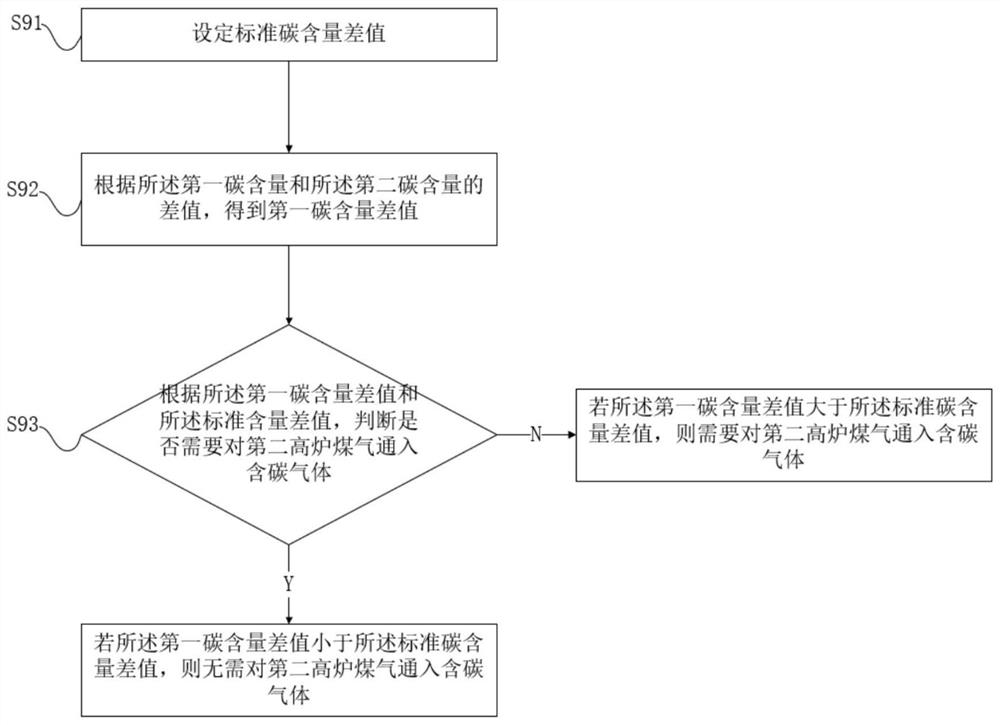

Method used

Image

Examples

Embodiment 1

[0133] It is determined that the first mixing, the second mixing and the carbon increase treatment are required,

[0134] The pressure of the first mixing was 3.3 MPa, and the pressure of the second mixing was 0.4 MPa.

[0135] The temperature of the first hot air and the second hot air was 1300°C.

[0136] In terms of volume fraction, both the first hot air and the second hot air include: O 2 : 25%, the rest is CO 2 .

Embodiment 2

[0138] Embodiment 2 and embodiment 1 are compared, and the difference between embodiment 2 and embodiment 1 is:

[0139] It is determined that the first mixing, the second mixing and the carbon increase treatment are required,

[0140] The pressure of the first mixing was 2.1 MPa, and the pressure of the second mixing was 0.3 MPa.

[0141] The temperature of the first hot air and the second hot air was 1200°C.

[0142] In terms of volume fraction, both the first hot air and the second hot air include: O 2 : 21%, the rest is CO 2 .

Embodiment 3

[0144] Embodiment 3 and embodiment 1 are compared, and the difference between embodiment 3 and embodiment 1 is:

[0145] It is determined that the first mixing, the second mixing and the carbon increase treatment are required,

[0146] The pressure of the first mixing was 4.2 MPa, and the pressure of the second mixing was 0.5 MPa.

[0147] The temperature of the first hot air and the second hot air was 1200°C.

[0148] In terms of volume fraction, both the first hot air and the second hot air include: O 2 : 30%, the rest is CO 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com