Bio-based antibacterial dental restoration material with high biocompatibility and preparation method thereof

A technology of biocompatibility and restorative materials, applied in the field of highly biocompatible bio-based antibacterial dental restoration materials and its preparation, can solve the problem of low antibacterial period and service life, reduction or disappearance of resin antibacterial ability, and influence on resin mechanics Performance and other issues, achieve significant antibacterial effect, strong inhibition, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

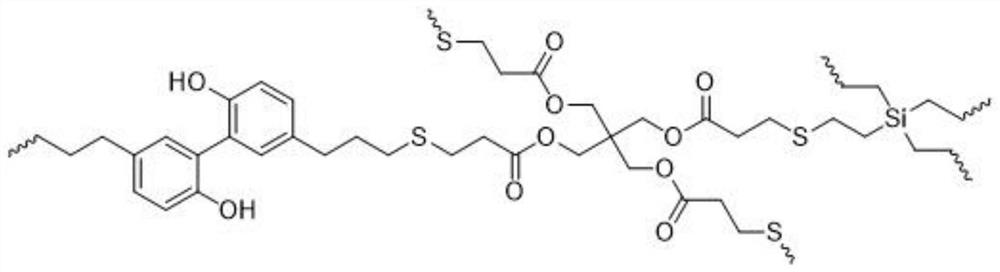

[0033] A preparation method of a bio-based antibacterial dental restoration material with high biocompatibility, comprising the following steps:

[0034] S1. Stir and mix 5',5-diallyl-2,2'-biphenyldiol and pentaerythritol tetramercaptoacetate at 110°C at a stirring speed of 200-400r / min to dissolve them completely. The mass-number ratio of 5',5-diallyl-2,2'-diphenol and pentaerythritol tetramercaptoacetate is 38-45:55-62;

[0035] S2. Add 2-isopropylthioxanthone (ITX) to the mixed solution obtained in step S1, stir until completely dissolved, the ratio of mass and number of 2-isopropylthioxanthone (ITX) to the mixed solution of S1 1~3:100;

[0036] S3, adding tetraethylenesilane into the mixed solution of S2, the mass-number ratio of the mixture of tetraethylenesilane and S2 is 20-40:100;

[0037] S4. Carrying out vacuum defoaming treatment at 110° C. in the mixed solution obtained in step S3 to obtain a white or yellow viscous bio-based antibacterial dental restorative mate...

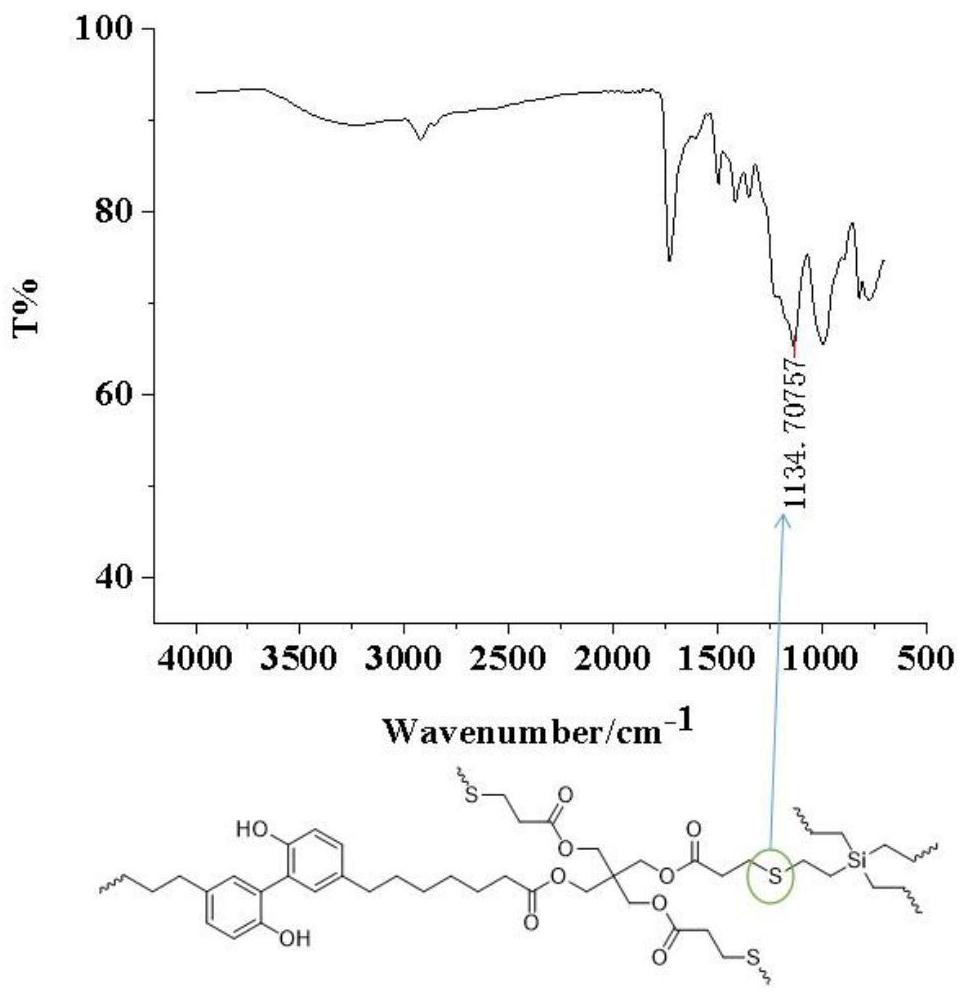

Embodiment 1

[0043] Example 1 of the present invention prepares a bio-based antibacterial material applied to dental restorative materials, comprising the following steps:

[0044] S1. Stir and mix 3.8g of 5',5-diallyl-2,2'-diphenol and 6.2g of pentaerythritol tetramercaptoacetate at 110°C at a stirring speed of 200r / min to make them completely dissolve;

[0045] S2. Add 100 mg of 2-isopropylthioxanthone (ITX) into the mixed solution obtained in step S1, and stir until completely dissolved;

[0046] S3, adding 2g of tetraethylenesilane into the mixed solution in step S2 and stirring evenly;

[0047] S4. The mixed solution obtained in step S3 is subjected to vacuum defoaming treatment at 110° C. to obtain a white or yellow viscous bio-based antibacterial dental restorative material with high biocompatibility.

[0048] The dental restorative material obtained in Example 1 was coated on a PTFE plate, and irradiated with 365nm ultraviolet light for 10 minutes to cure the dental material, and...

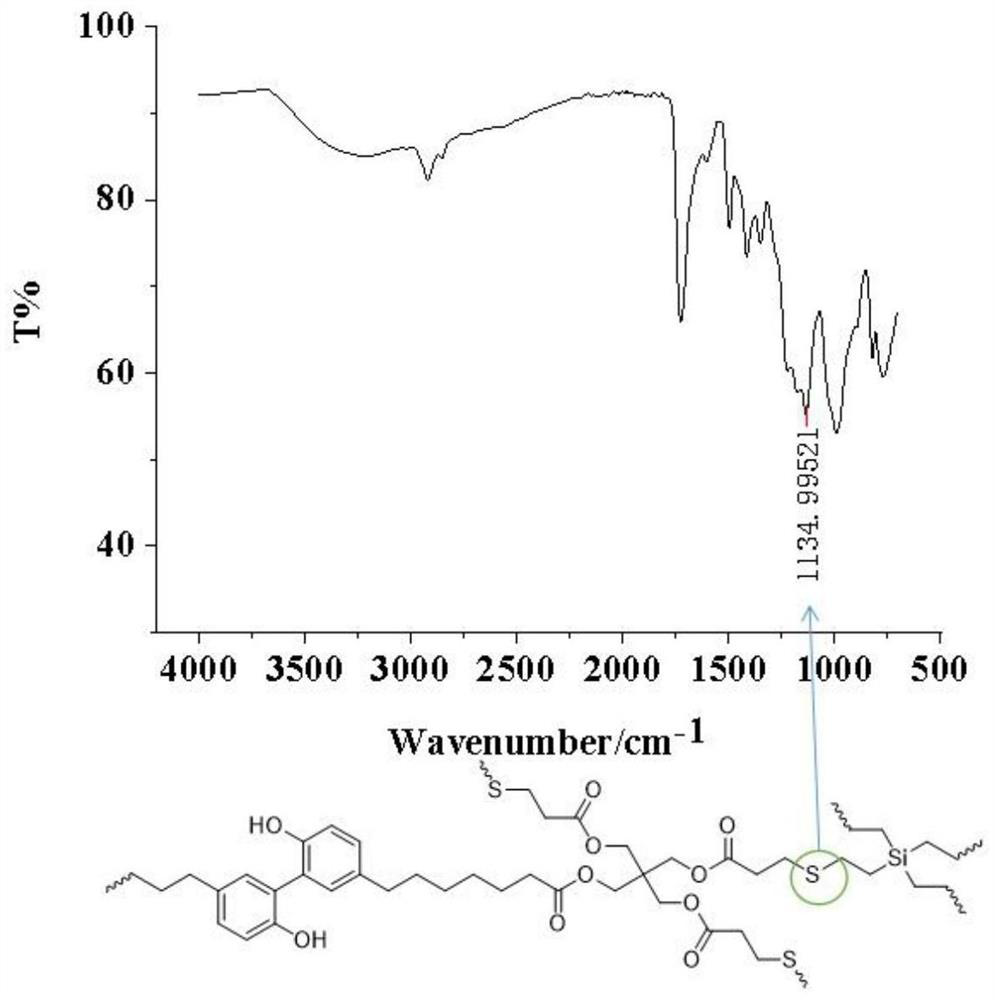

Embodiment 2

[0053] Example 2 of the present invention prepares a bio-based antibacterial material applied to dental restorative materials, comprising the following steps:

[0054] S1. Stir and mix 4.5g 5',5-diallyl-2,2'-diphenol and 5.5g pentaerythritol tetramercaptoacetate at 110°C at a stirring speed of 200r / min to make them completely dissolve;

[0055] S2. Add 300mg of 2-isopropylthioxanthone (ITX) into the mixed solution obtained in step S1, and stir until completely dissolved;

[0056] S3, adding 4g of tetraethylenesilane into the mixed solution of S2 and stirring evenly;

[0057] S4. The mixed solution obtained in step S3 is subjected to vacuum defoaming treatment at 110° C. to obtain a white or yellow viscous bio-based antibacterial dental restorative material with high biocompatibility.

[0058] The dental restorative material obtained in Example 2 was coated on a PTFE plate, and irradiated with ultraviolet light with a wavelength of 365nm for 10 minutes to cure the dental mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com