Connecting end drilling production line of epoxy glass fiber pipe

A technology of epoxy glass fiber pipe and epoxy glass fiber, which is applied in the field of the connection end drilling production line of epoxy glass fiber pipe, can solve the problems that dust cannot be collected and discharged, processing equipment is difficult to erect, and processing difficulty is large, so as to reduce the Reduce labor intensity, ensure processing quality, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

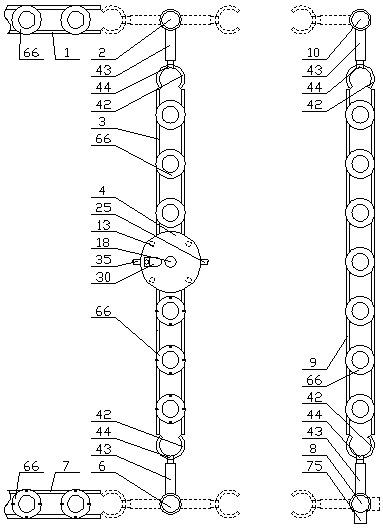

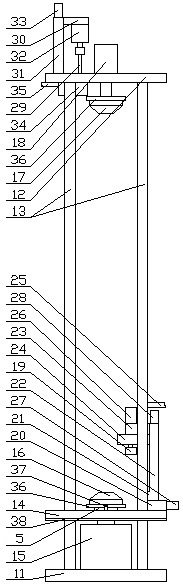

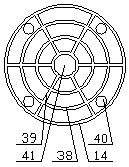

[0061] combine Figure 1~Figure 7 It can be seen that the connection end drilling production line of epoxy fiberglass pipes includes the feeding conveying frame 1, the grabbing device A2, the drilling conveying frame 3, the grabbing device B6 and the discharging conveying frame 7 arranged in sequence along the pipeline conveying direction, The drilling transmission frame 3 passes through the drilling machine 4, and the feeding transmission frame 1 and the discharging transmission frame 7 are respectively arranged on the same side of the two ends of the drilling transmission frame 3, and the other side of the drilling transmission frame 3 The side is provided with a return material transfer frame 9, and the two ends of the return material transfer frame 9 are respectively provided with a grabbing device C8 and a grabbing device D10; the grabbing device A2 feeds the epoxy glass fiber The pipe 66 or the epoxy glass fiber pipe 66 of the gripping device D10 is delivered to the dril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com