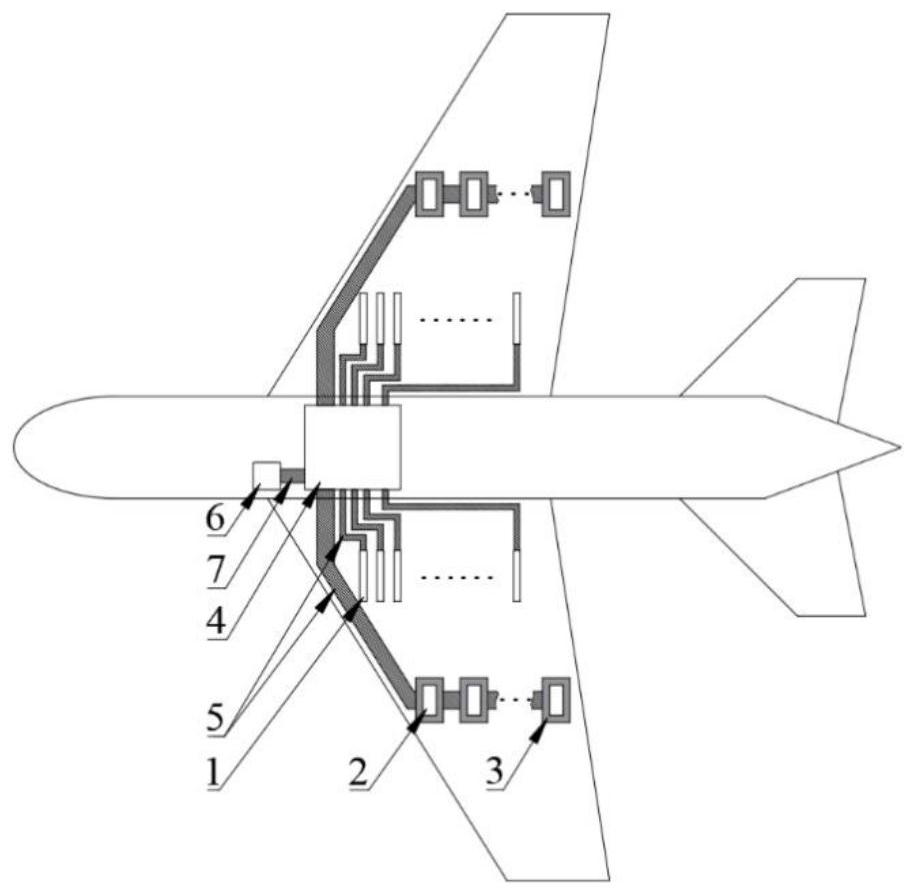

Online flight testing system and testing method thereof

A flight test and flight control system technology, which is applied in the testing of machines/structural components, measuring devices, aerodynamic tests, etc., can solve the problem of inability to accurately obtain wall shear stress and pressure information, and achieve light weight and small impact , the effect of strong conformal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

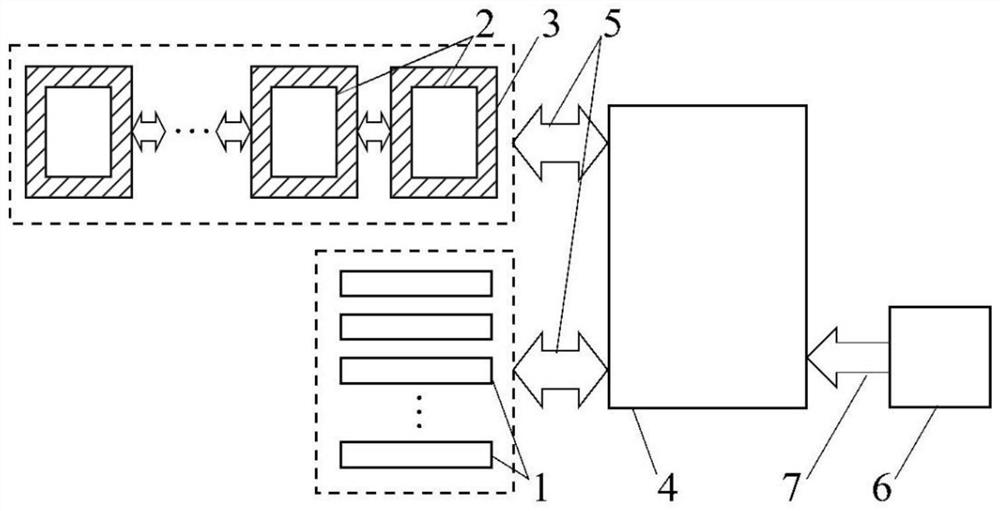

[0050] The shear stress test node module is electrically connected to the tester in parallel mode, and the stress test node module is electrically connected to the tester in series mode.

[0051] In the parallel mode, each node is connected to the tester separately, and the tester performs excitation and signal processing; in the series mode, the first node is connected to the tester, and the subsequent nodes are connected to the previous one by one. node.

[0052] The series mode test node includes a flexible substrate, a control unit and a sensing unit. The sensing unit is a piezoresistive, piezoelectric or capacitive pressure sensor. The control unit is used for controlling the signal acquisition of the sensor to be synchronized with the network.

Embodiment 2

[0054] The shear stress test node module is electrically connected to the tester in series mode, and the pressure test node module is electrically connected to the tester in parallel mode.

[0055] In the parallel mode, each node is connected to the tester separately, and the tester performs excitation and signal processing; in the series mode, the first node is connected to the tester, and the subsequent nodes are connected to the previous one by one. node.

[0056] The series mode test node includes a flexible substrate, a control unit and a sensing unit. The sensing unit is a floating, thermal or bottom partition wall shear stress sensor. The control unit is used for controlling the signal acquisition of the sensor to be synchronized with the network.

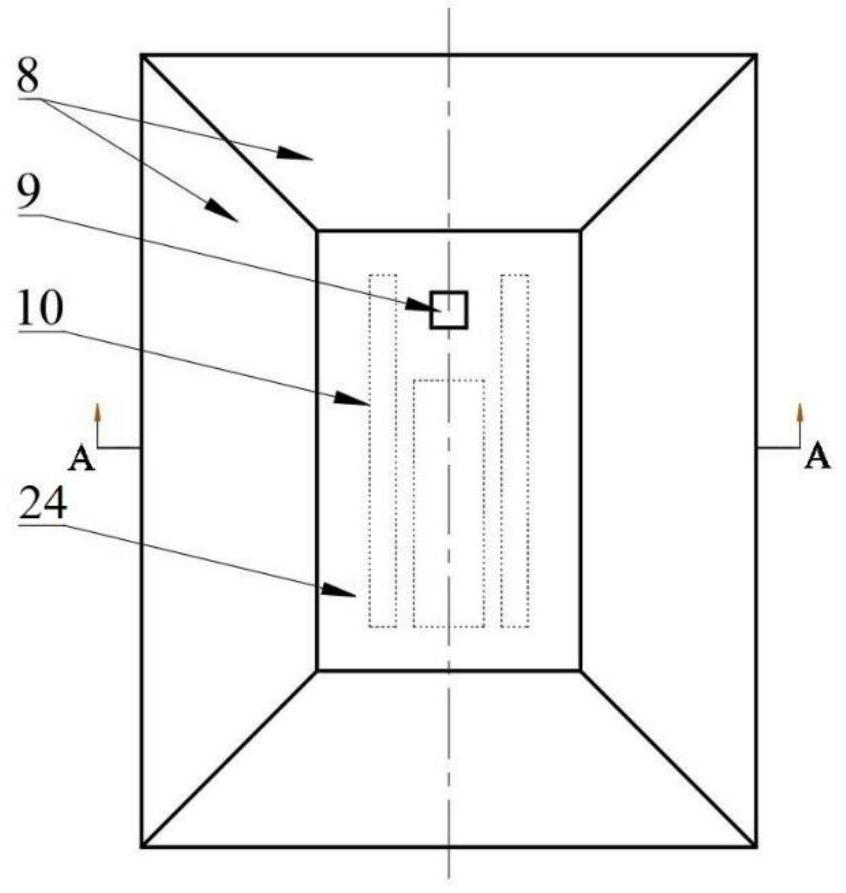

[0057] In Embodiment 1 and Embodiment 2, a first node fairing and a second node fairing are respectively attached above the shear stress test node module and the pressure test node module.

[0058] See image 3 and Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com