High-dimensional ultrasonic evaluation method for grain size of nickel-based alloy

A grain size, nickel-based alloy technology, applied in the direction of using ultrasonic/sonic/infrasonic, particle size analysis, particle and sedimentation analysis, etc., can solve the problems of model construction difficulties, evaluation model dimension growth, model construction difficulties, etc. Limitations, solving the large amount of multi-parameter calculation, reducing the effect of model calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

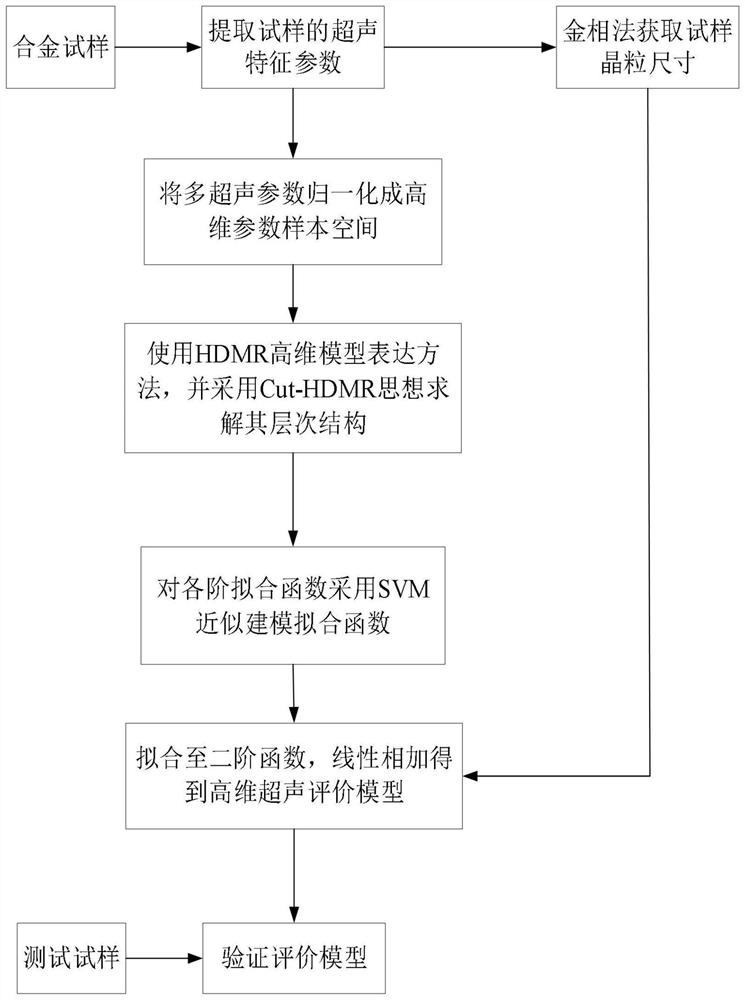

[0053] High-dimensional ultrasonic evaluation method for nickel-based alloy grain size:

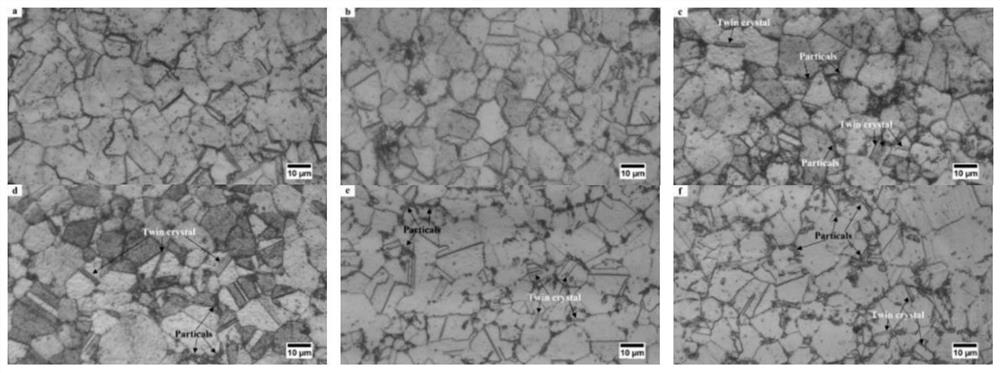

[0054] S1. Use the 5077PR pulse signal generator and the immersion pulse reflection method with a detection frequency of 10MHz to conduct an ultrasonic detection experiment on the sample, and then conduct ultrasonic detection on the reference test block and record the ultrasonic characteristic parameters, and perform metallographic sample preparation. average grain size;

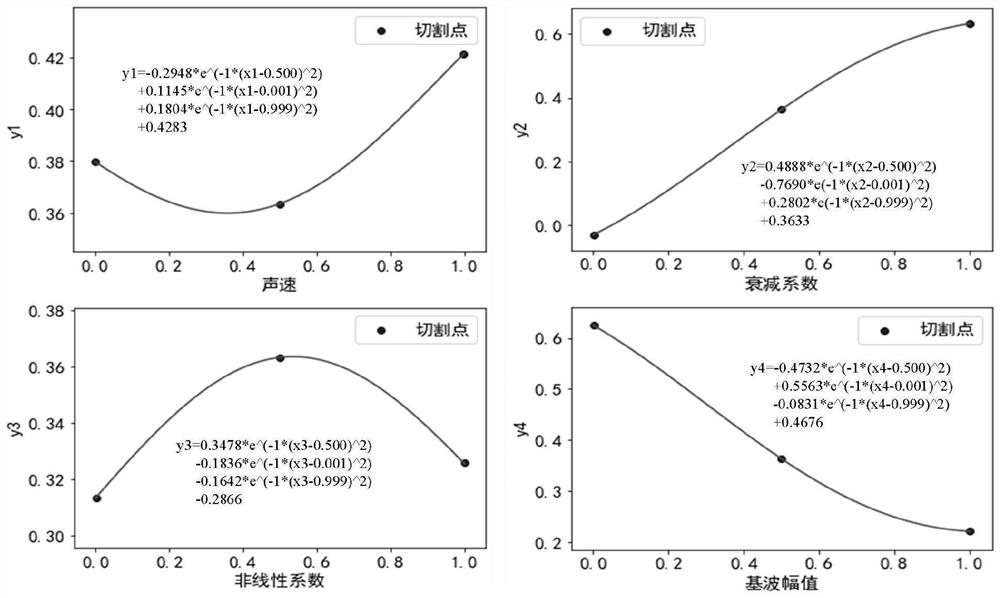

[0055] S2. Construct ultrasonic evaluation parameters. According to the principle of correlation, the ultrasonic parameters select sound velocity, attenuation coefficient, nonlinear coefficient and fundamental wave amplitude, and normalize them, and set them as high-dimensional parameter space.

[0056] Normalize the input space of the selected ultrasonic parameter variables, and use 0-1 normalization, the formula is:

[0057]

[0058] Ω={X=(x 1 ,x 2 ,x 3 ,x 4 )∈R 4 ,0i <1} (2).

[0059] where x 1 is the spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com