High-solid-content waterborne polyurethane and preparation method thereof

A technology of water-based polyurethane and high solid content, applied in the field of polyurethane materials, can solve the problems of low solid content of water-based polyurethane, and achieve the effect of solving environmental pollution and excellent resistance to ultraviolet aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

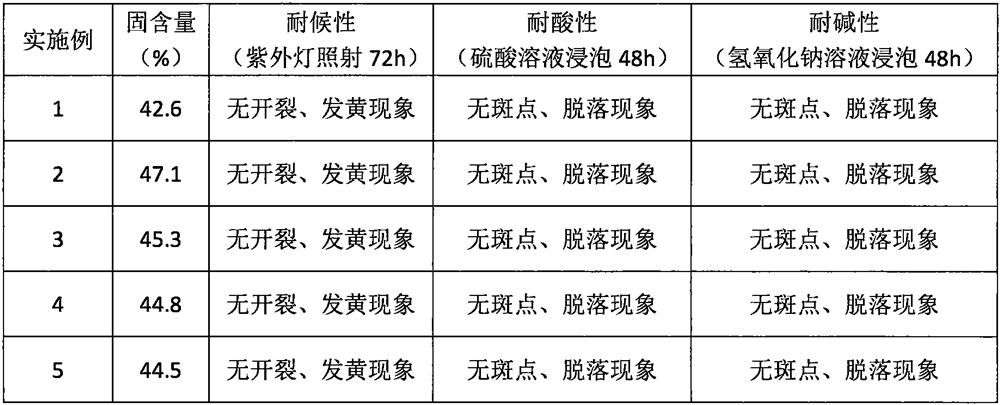

Examples

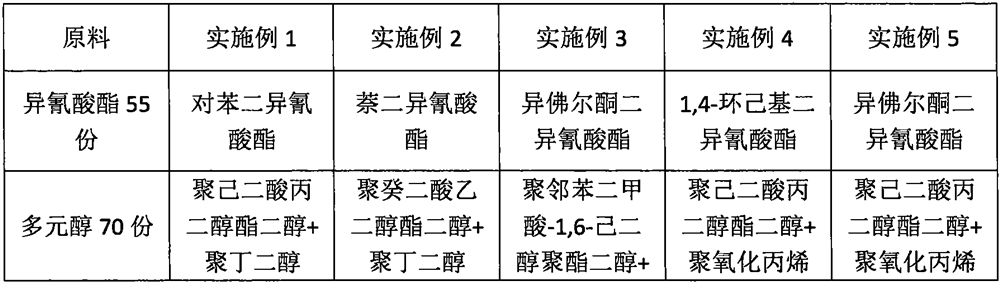

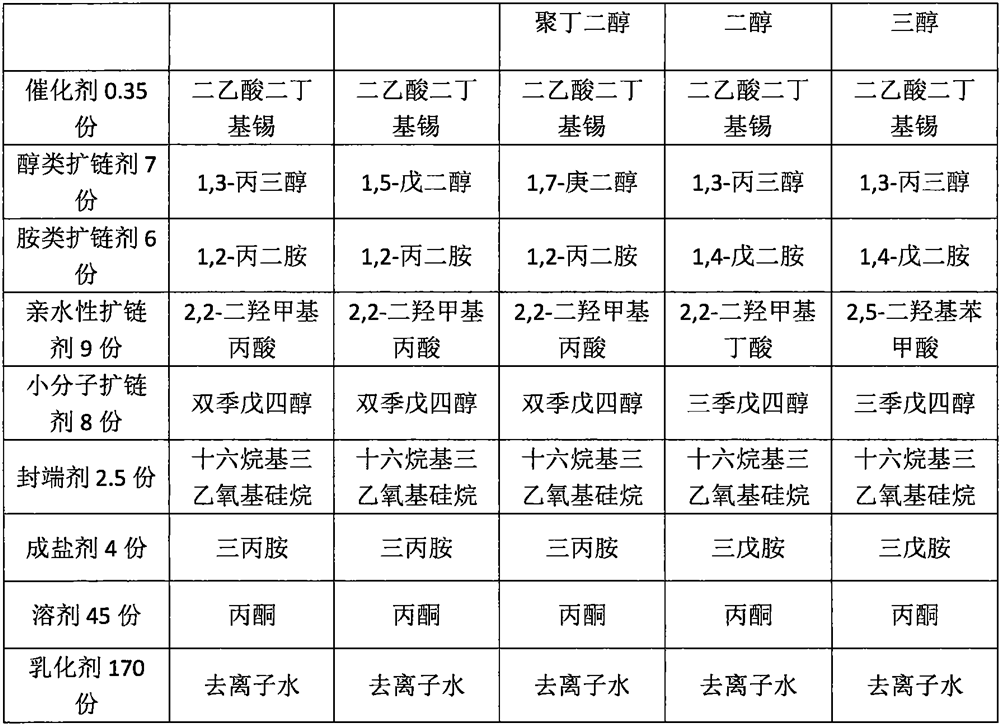

Embodiment 1 Embodiment 1~5

[0030] Embodiment 1 Embodiment 1~5 is prepared according to the following steps:

[0031] a. Dry polyols, alcohol chain extenders, amine chain extenders, hydrophilic chain extenders, and small molecule chain extenders at 100-120°C for 2-3 hours in vacuum before use;

[0032] b. Add solvents, isocyanates and polyols in proportion to a dry three-necked flask with a stirrer, a thermometer and a reflux condenser;

[0033] c. continue to add a certain amount of tin catalyst, in N 2 Under protection, react at 40-60°C for 20-40 minutes, then raise the temperature to 70-80°C and continue to react for 60-80 minutes;

[0034] d. Add hydrophilic chain extender and alcohol chain extender in proportion and raise the temperature to 90-95°C for 40-50 minutes, then continue to add amine chain extender in proportion to react for 30-40 minutes;

[0035] e. Add a small molecule chain extender in proportion to continue the reaction for 30-40 minutes, then add a certain amount of salt-forming ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com