Flow divider and air conditioner comprising same

A shunt and shunt technology, applied in the direction of fluid circulation arrangement, refrigeration components, refrigerators, etc., can solve the problems of reducing heat exchange efficiency, reducing refrigerant circulation, narrowing the main channel, etc., to increase refrigerant circulation and refrigerant circulation. The effect of increasing the volume and improving the structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

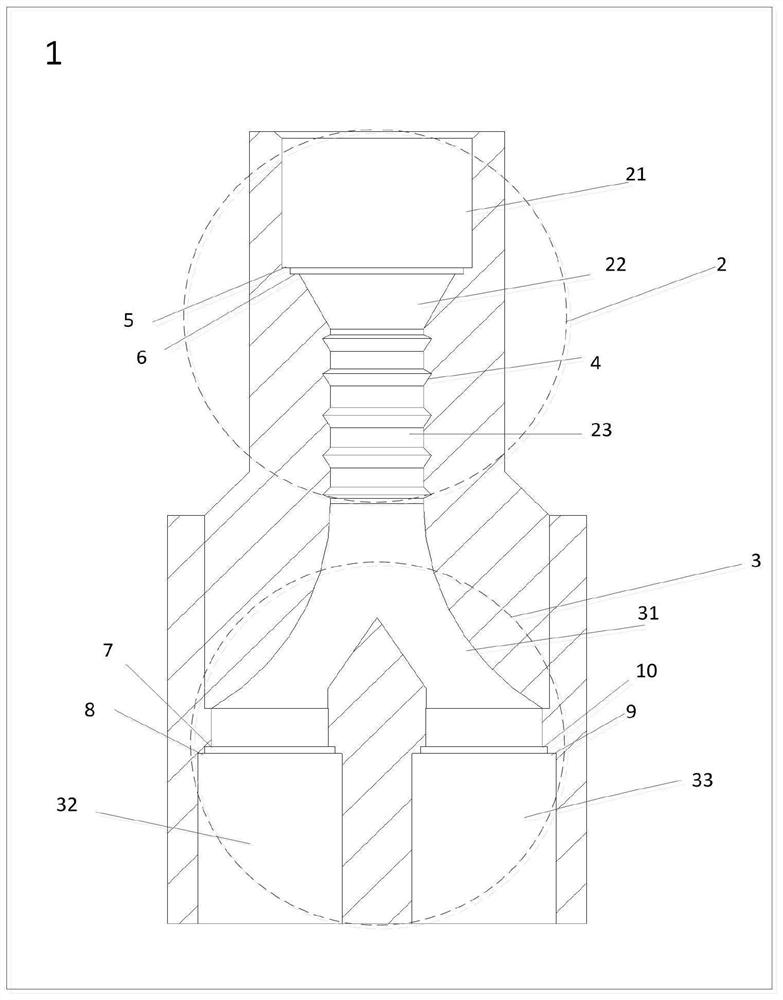

[0040] Example 1, please refer to figure 1 , figure 1 is a schematic cross-sectional view of the flow divider in the embodiment of the present application.

[0041] The flow divider 1 of the present application includes a main channel 2 and a branch channel 3 connected thereto. The main channel 2 includes a wide-diameter portion 21 and a narrow-diameter portion 23. The wide-diameter portion 21 is a relatively wide flow channel of the main channel, so The narrow-diameter portion 23 is a relatively narrow flow channel for the main flow channel, and a hollow ring groove 4 with a trapezoidal cross section is set in the narrow-diameter portion 23, see figure 1 , when the main flow channel 2 and the first branch branch 32 and the second branch branch 33 are on the same plane as the first viewing angle, in this viewing angle, the plane perpendicular to the radial direction of the main flow channel is taken as the section, the The radial direction is the direction of the radius or d...

Embodiment 2

[0043] Embodiment 2, in order to further increase the flow of refrigerant in the flow divider, the structural strength of the tank wall can be further strengthened, so that the tank wall of the flow divider can be made thinner, please refer to Figure 2-Figure 6 ,Specifically:

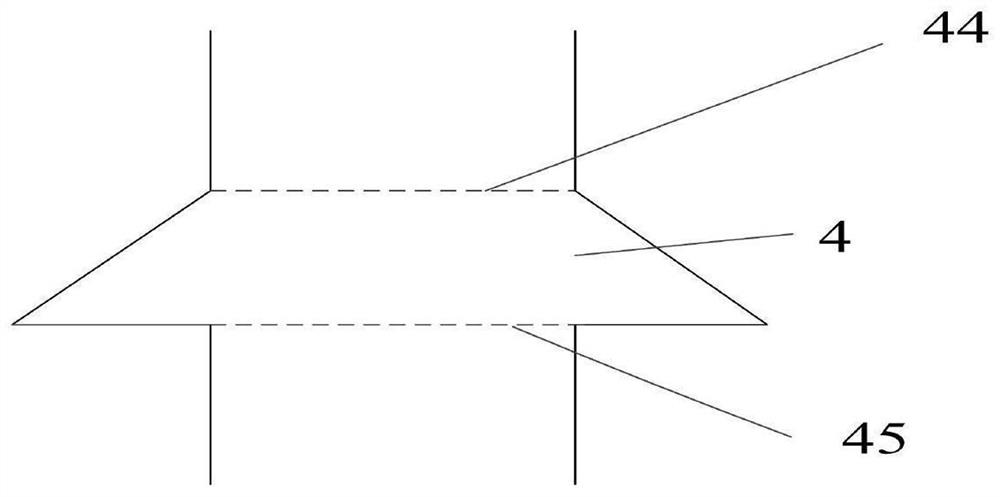

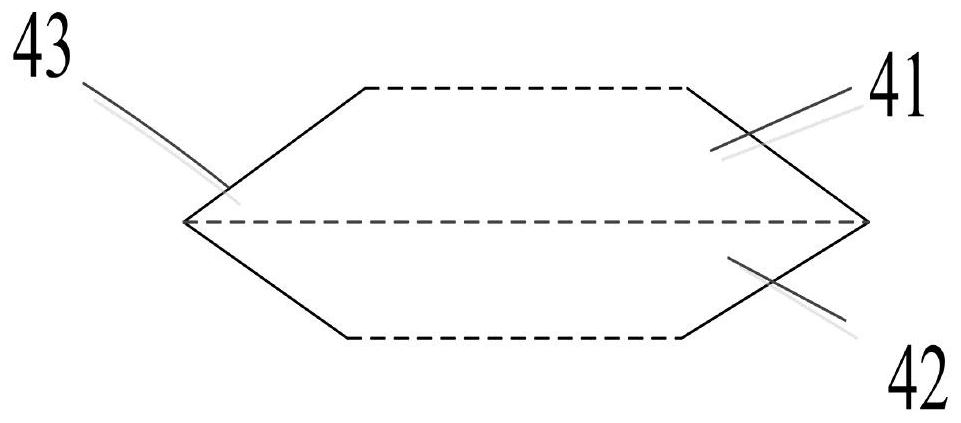

[0044] Based on the structure of the first embodiment above, at least two hollow ring grooves 4 are provided in the narrow diameter portion 23 .

[0045] see figure 2, the parallel short sides of the trapezoid that the cross section of the hollow ring groove 4 presents is the groove top 44, and the parallel long sides of the trapezoid that the cross section of the hollow ring groove 4 presents is the groove bottom 45, when at least two hollow ring grooves are set at the narrow diameter portion 23 4 o'clock, including the first hollow ring groove 41 and the second hollow ring groove 42, in the hollow ring groove, the groove top 44 close to the wide diameter part 21 is the first hollow ring groove 41, ...

Embodiment 3

[0052] Embodiment 3, when the refrigerant fluid flows into the flow divider, due to the fast flow speed, the refrigerant fluid hits the wall of the flow divider and generates a lot of noise. In order to solve the above problems, this application proposes a corresponding solution, please refer to Figure 7 ,Specifically:

[0053] see Figure 7 , on the basis of Embodiment 1, when at least two hollow ring grooves 4 are provided on the narrow diameter portion 23, the acute angles of the trapezoidal shapes presented by the cross sections of the first hollow ring groove 41 and the second hollow ring groove 42 are different. The acute angles are not the same, which means that when there are only two hollow ring grooves, the trapezoidal acute angles of the sections of the two hollow ring grooves are different. When there are three or more hollow ring grooves, at least one hollow ring groove The acute angle of the trapezoid presented by the section of the groove is different from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com