Fabrication method of gan-based micro-led structure and gan-based micro-led array

A manufacturing method and semiconductor technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of semiconductor layer and quantum well layer damage, affecting LED luminous efficiency, complex cutting process, etc., to overcome sidewall damage, cleavage The operation is easy to realize and overcome the effect of mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In view of the deficiencies in the prior art, the inventor of this case was able to propose the technical solution of the present invention after long-term research and extensive practice. The technical solution, its implementation process and principle will be further explained as follows.

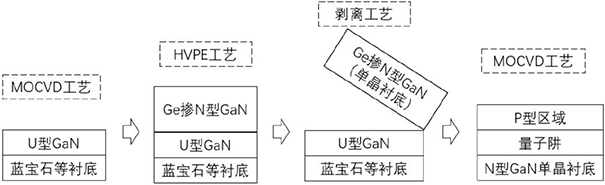

[0038] A method for fabricating a GaN-based Micro-LED structure provided by one aspect of the present invention includes:

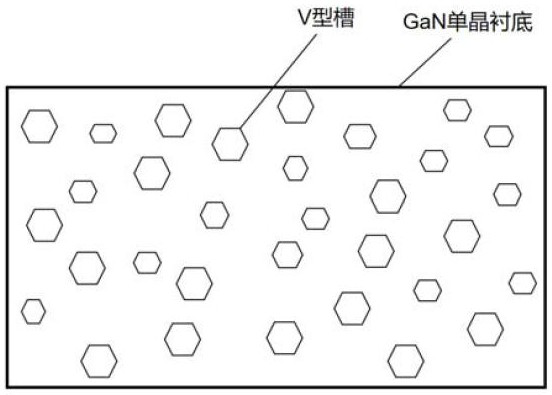

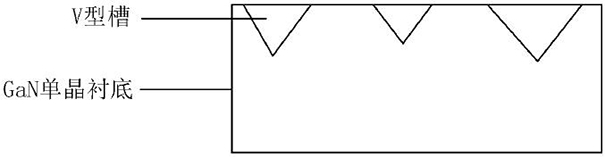

[0039] preparing a first semiconductor layer of the first conductivity type, wherein a plurality of depressions are formed on the surface of the first semiconductor layer, and the diameters and depths of the plurality of depressions are different;

[0040] A patterned mask is provided on the surface of the first semiconductor layer, and at least one first strip-shaped opening and at least one second strip-shaped opening are opened on the patterned mask, and the first strip-shaped opening and the second strip-shaped opening are The strip-shaped openings inters...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com