Roll type production device and method for aerogel composite material

A technology of composite materials and production equipment, applied in the direction of coating, etc., can solve the problems of complicated operation and poor environmental protection, and achieve the effect of simple operation, high accuracy and avoiding repeated hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

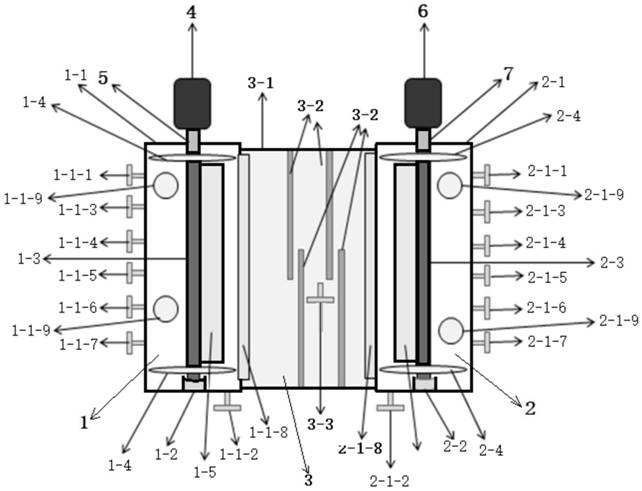

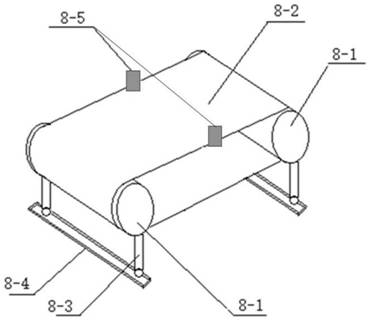

[0045] Example 1: The airgel composite roll production device of the present embodiment consists of open tank 1, a receiving tank 2, a sealing glove box 3, a first rotating motor 4, a first coupling 5, a second rotating motor 6 , The second coupling 7 and the tetrafluorogenic transmission platform are composed;

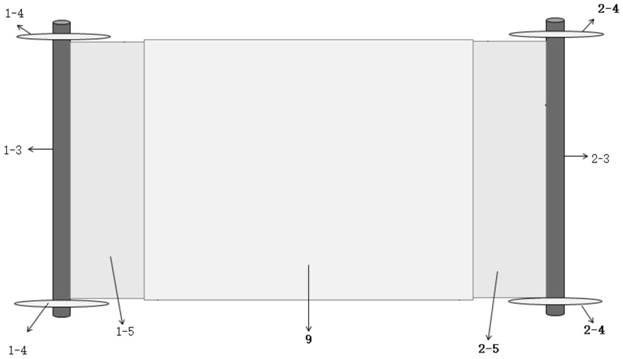

[0046] Among them, the open-can 1 is composed of a cylinder 1-1, a first fixing groove 1-2, a first central rotating shaft 1-3, two first porous baffles 1-4, and the first tetrafluoro-traction belt 1-5. The first feed port 1-1-1, the first row of liquid ports 1-1-2, the first test opening 1-1-3, first measurement port 1-1-3, first measurement Port 1-1-4, first extravagant air port 1-1-5, first inert gas inlet 1-1-6, first exhaust air outlet 1-1-7; on the side wall of the open tank 1-1 Set the first fast opening door 1-1-8 parallel to the axis; the first central rotation shaft 1-3 is disposed at the axial position of the open tank 1-1, and one end of the first central rota...

Embodiment 2

[0064] Example 2: A method of producing an airgel composite material, and is different from that of Example 1: When the negative pressure extract is glue, the incurred pressure is aspected to -0.095 MPa, and the other is the same as in Example 1. The vacuum is slightly low, and the amount of sol glid is slightly low, reducing the cost of the raw material, and the airgel composite material is slightly small due to the internal airborne powder, so the thermal conductivity is substantial, but the product thermal conductivity can also achieve the market. Existing product levels.

Embodiment 3

[0065] Example 3: A method of producing an airgel composite material, in fact, in Example 1: When drying, pump the incurns to -0.099MPa, and adjust the tank temperature to 80 ° C, dry, other Example 1 was the same. The drying temperature is lowered, and the solvent in the airgel composite is slow, so the internal airgeret powder hole is kept better, it is not easy to collapse, and the obtained product has a larger surface area and the thermal conductivity is lower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com