Gluing process for replacing adhesive film

A process and film technology, which is applied in the field of glazing technology to replace film, can solve the problems of folding resistance, breaking resistance, high cost, etc., and achieve the effect of saving cost, saving waiting time and meeting the requirements of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

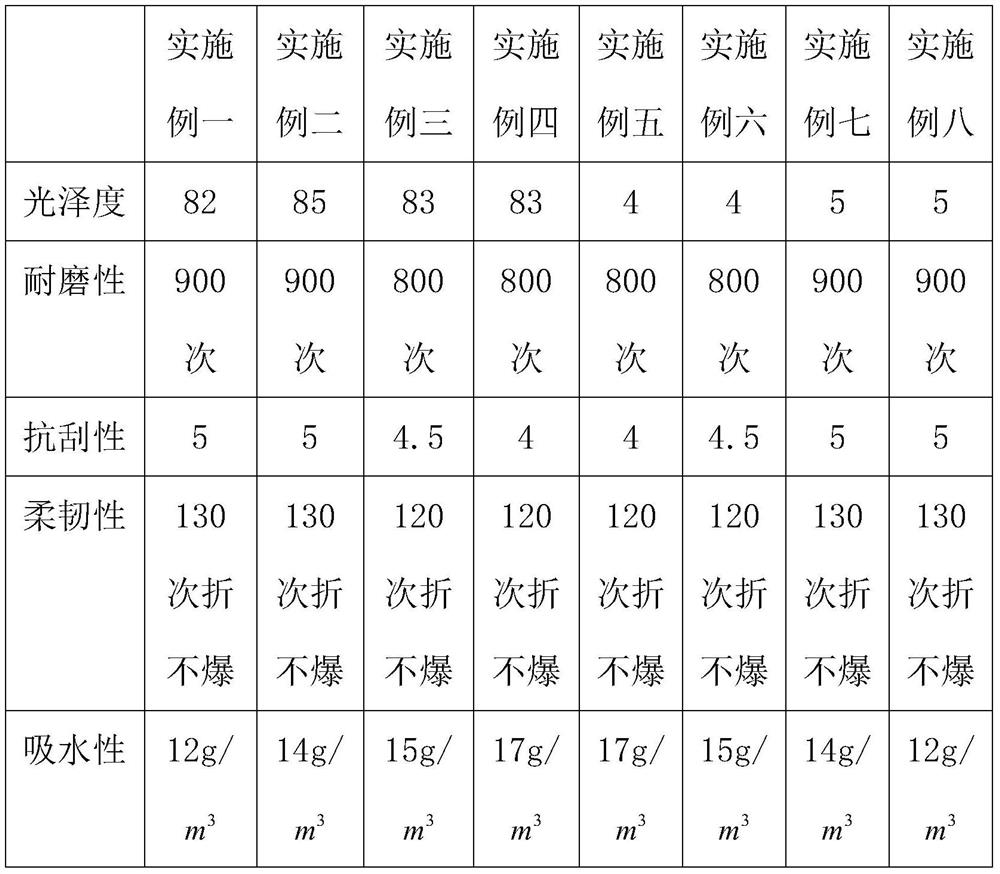

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with specific embodiments.

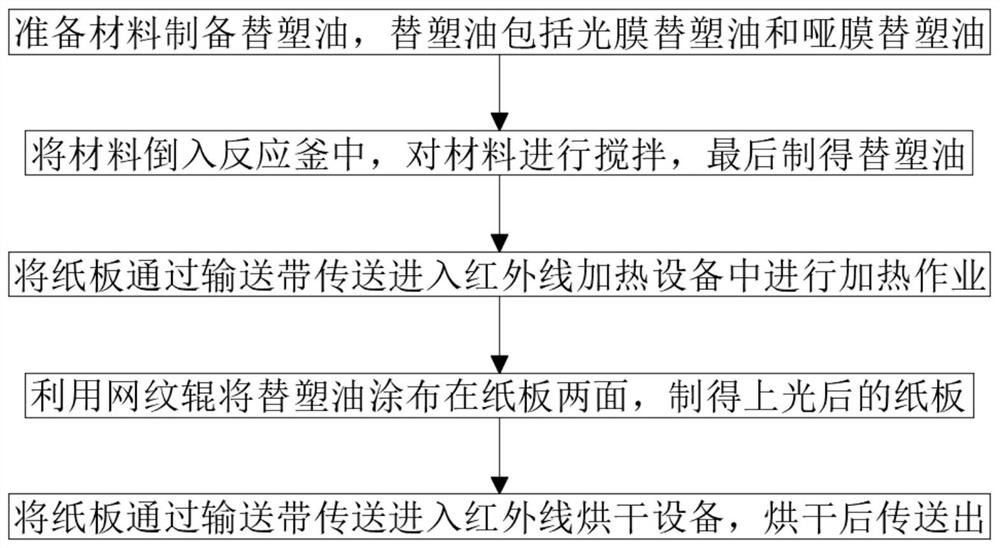

[0024] refer to figure 1 , embodiment one

[0025] In this embodiment, a glazing process for replacing the adhesive film is proposed, including the following steps:

[0026] S1: Prepare materials to prepare plastic replacement oil, materials include resin material, special resin material, water-based wax emulsion, silica matting powder, polymer dispersant, humectant, wear-resistant wax slurry H-859, ethanolamine regulator, auxiliary agent And polyurethane polymers, special resin materials include hydroxyethyl acrylate copolymer and viscosity adjusting resin H-8905, the specific gravity of hydroxyethyl acrylate copolymer and viscosity adjusting resin H-8905 is 6:4, plastic replacement oil includes glossy film replacement Plastic oil, glossy plastic replacement oil includes 90 parts of resin material, 25 parts of special resin material, 10 parts of water-based wax emulsion,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com