Saponification wastewater and desulfurization wastewater combined pretreatment process

A technology of saponification wastewater and desulfurization wastewater, which is applied in the direction of neutralization water/sewage treatment, water/sludge/sewage treatment, gaseous discharge wastewater treatment, etc., can solve the problem of high treatment cost, achieve good treatment effect, save resources, The effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

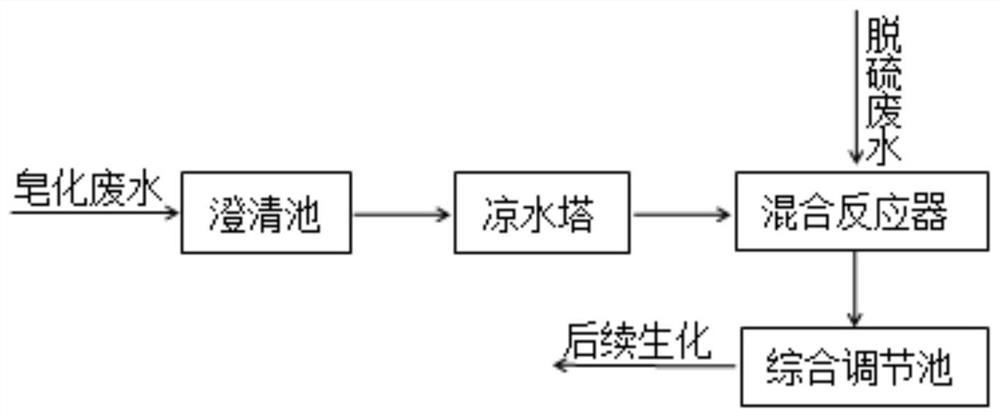

[0017] A combined pretreatment process of saponification wastewater and desulfurization wastewater, the treatment steps are as follows:

[0018] (1) In the process of preparing propylene oxide by the chlorohydrin method, the waste water generated in the saponification process enters the clarification tank for sedimentation, and the mud at the bottom of the clarification tank is pumped into the filter press system through a mud pump, and the treated filtrate and the supernatant of the clarification tank are jointly pumped into the The cooling tower is used to cool down; the sedimentation ratio reaches more than 95%.

[0019] (2) The saponification wastewater after cooling down to below 38°C and the desulfurization wastewater produced by the thermal power plant are put into the mixing reactor at a ratio of 4:1 for thorough reaction, the bottom sediment is quickly extracted, and the supernatant is transferred to the comprehensive adjustment tank Follow-up biochemical and advanced...

Embodiment 2

[0022] A combined pretreatment process of saponification wastewater and desulfurization wastewater, the treatment steps are as follows:

[0023] (1) In the process of preparing propylene oxide by the chlorohydrin method, the waste water generated in the saponification process enters the clarification tank for sedimentation, and the mud at the bottom of the clarification tank is pumped into the filter press system through a mud pump, and the treated filtrate and the supernatant of the clarification tank are jointly pumped into the The cooling tower is used to cool down; the sedimentation ratio reaches more than 95%.

[0024] (2) The saponification wastewater after cooling down to below 38°C and the desulfurization wastewater produced by the thermal power plant are put into the mixing reactor at a ratio of 5:1 for thorough reaction, the bottom sediment is quickly extracted, and the supernatant is transferred to the comprehensive adjustment tank for further processing Subsequent ...

Embodiment 3

[0027] A combined pretreatment process of saponification wastewater and desulfurization wastewater, the treatment steps are as follows:

[0028] (1) In the process of preparing propylene oxide by the chlorohydrin method, the waste water generated in the saponification process enters the clarification tank for sedimentation, and the mud at the bottom of the clarification tank is pumped into the filter press system through a mud pump, and the treated filtrate and the supernatant of the clarification tank are jointly pumped into the The cooling tower is used to cool down; the sedimentation ratio reaches more than 95%.

[0029] (2) The saponification wastewater after cooling down to below 38°C and the desulfurization wastewater generated by the thermal power plant are put into the mixing reactor at a ratio of 6:1 for thorough reaction, the bottom sediment is quickly extracted, and the supernatant is transferred to the comprehensive adjustment tank for further processing Subsequent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sedimentation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com