Disassembly-free outer wall outer formwork based on vacuum insulated panel

A technology of vacuum insulation panels and vacuum insulation, which is applied in the directions of walls, insulation improvement, climate change adaptation, etc., can solve the problems of lack of compact and continuous structural forms, reduced thermal insulation performance of vacuum insulation panels, and restrictions on the wide application of vacuum insulation panels, etc. Achieve the effect of improving bonding reliability, simplifying construction procedures, and avoiding secondary construction operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

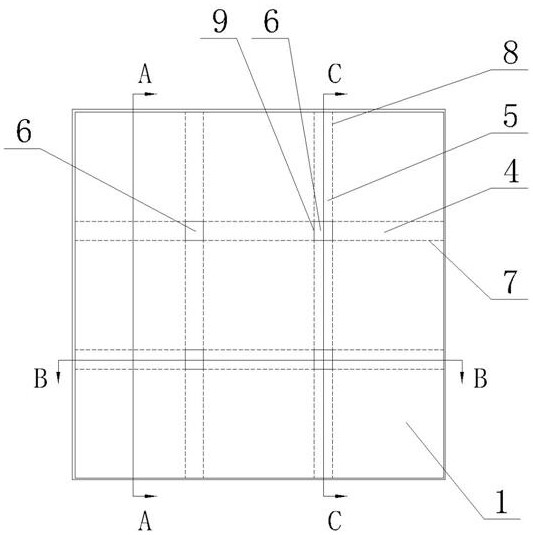

[0024] Specific implementation mode one: as Figure 1 to Figure 10 As shown, this specific embodiment adopts the following technical solutions: including outer layer panels 1, inner layer panels 2, multiple vacuum insulation square panels 3, multiple first vacuum insulation strip panels 4, and multiple second vacuum insulation panels. Insulation strip panels 5 and a plurality of plugs 6, the outer panel 1 and the inner panel 2 are arranged vertically side by side, the inner side of the inner panel 2 is arranged facing the outer wall of the building, and a plurality of vacuum insulation square panels 3 are arranged in a rectangular array The form is arranged on the outer surface of the inner layer board 2, and a plurality of transverse gaps 7 and a plurality of longitudinal gaps 8 are formed between a plurality of vacuum heat insulation square plates 3, and the plurality of transverse gaps 7 are along the length direction of the inner layer board 2 Arranged in order from top to...

specific Embodiment approach 2

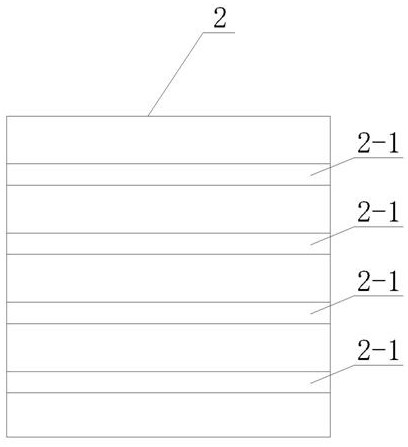

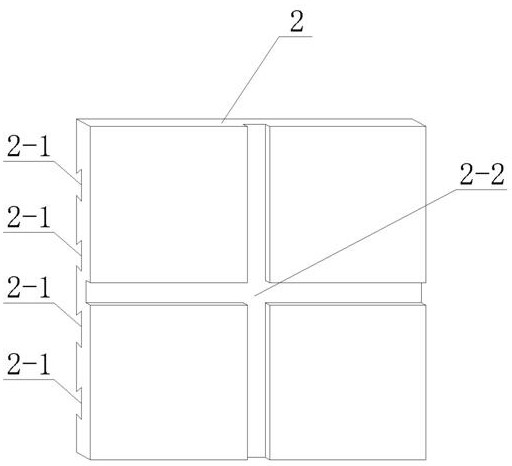

[0027] Specific embodiment 2: This embodiment is a further limitation of specific implementation 1. A plurality of tanks 2-1 are processed side by side on the inner surface of the inner plate 2, and the distance between adjacent tanks 2-1 is 200~300mm. .

specific Embodiment approach 3

[0028] Embodiment 3: This embodiment is a further limitation of Embodiment 1 or 2. The outer surface of the inner plate 2 is processed with a moisture drainage channel 2-2. The moisture removal channel 2-2 is used to provide a space for dehumidification and ventilation for each vacuum insulation square panel 3 , the first vacuum insulation strip panel 4 and the second vacuum insulation strip panel 5 that are in direct contact with the inner layer panel 2 and location.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com