Paint spraying waste gas treatment device for glass bottle production

A technology for waste gas treatment device and glass bottle, which is applied in the directions of gas treatment, combination device, separation method, etc., can solve the problems of user and environmental loss, poor air filtration effect, atmospheric air pollution, etc., and achieves simple structure, good effect, Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

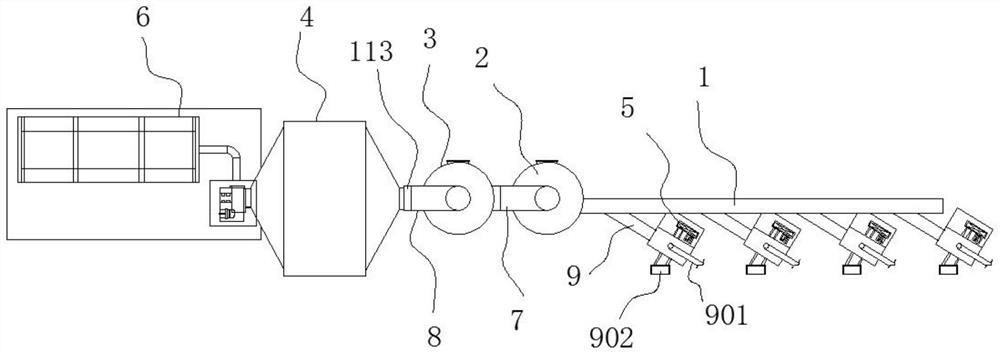

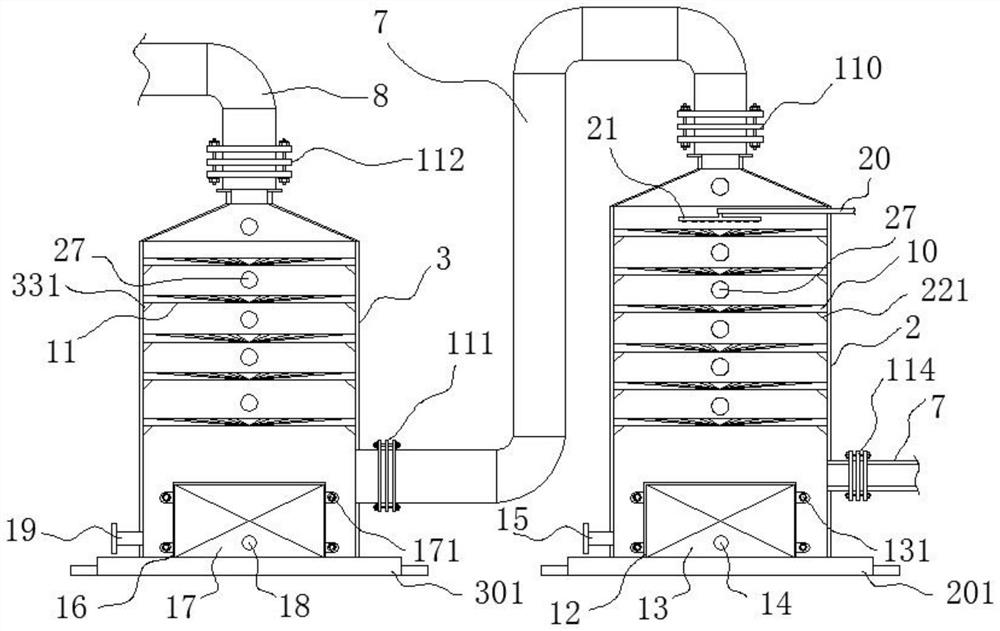

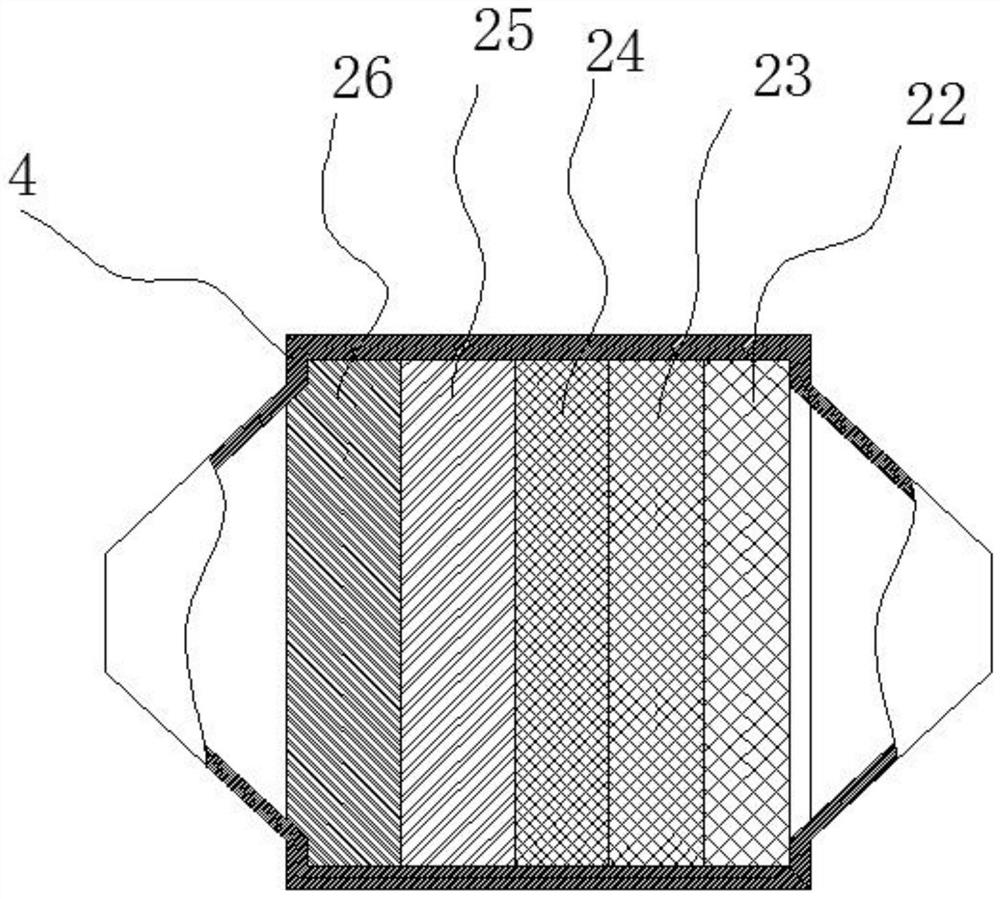

[0019] refer to Figure 1 to Figure 5 The shown a kind of spray paint exhaust gas treatment device for glass bottle production includes air pipe 1, spray tower 2, defogging tower 3, filter device 4, water spray fan 5 and RTO zeolite runner catalytic combustion integrated machine 6, the The output end of the air pipe 1 is connected with the spray tower 2, the upper end of the spray tower 2 is connected with a first air pipe 7, and the output end of the first air pipe 7 is connected with the defogging tower 3, and the defogging The upper end of the tower 3 is connected with a second air pipe 8, the output end of the second air pipe 8 is connected with the filter device 4, and the output end of the filter device 4 is connected with the RTO zeolite runner catalytic combustion integrated machine 6 by a pipeline, so One side of the air pipe 1 is connected with an air inlet pipe 9, the water spray fan 5 is connected with the air inlet pipe 9, and the output end of the water spray fan...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap