Method for constructing super-hydrophobic PVDF nanofiber membrane based on interface self-polymerization and application of super-hydrophobic PVDF nanofiber membrane

A nanofiber membrane and nanofiber technology, applied in separation methods, chemical instruments and methods, membranes, etc., can solve the problems of complex operation in the preparation process, complex modification devices, uneven modification of porous carriers, etc., and achieve simple preparation process , increased permeation flux, and large industrial application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

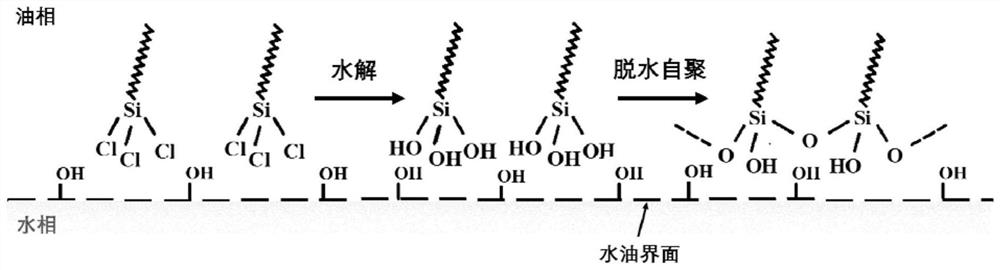

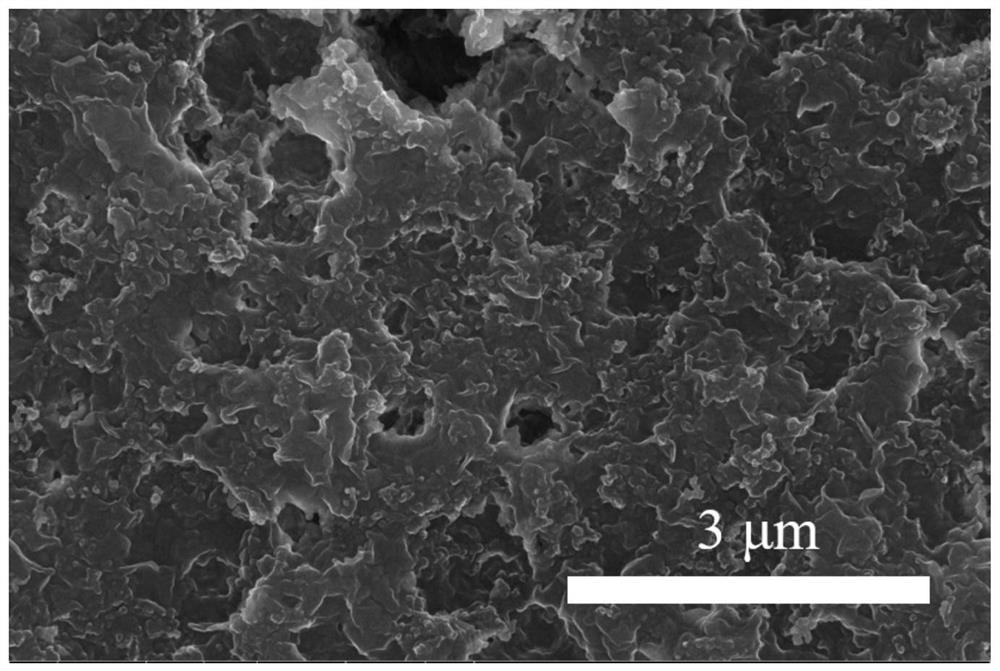

[0035] The method for constructing a superhydrophobic PVDF nanofiber membrane based on interfacial self-aggregation proposed by the present invention is used to prepare a superhydrophobic PVDF nanofiber membrane, which specifically includes the following steps:

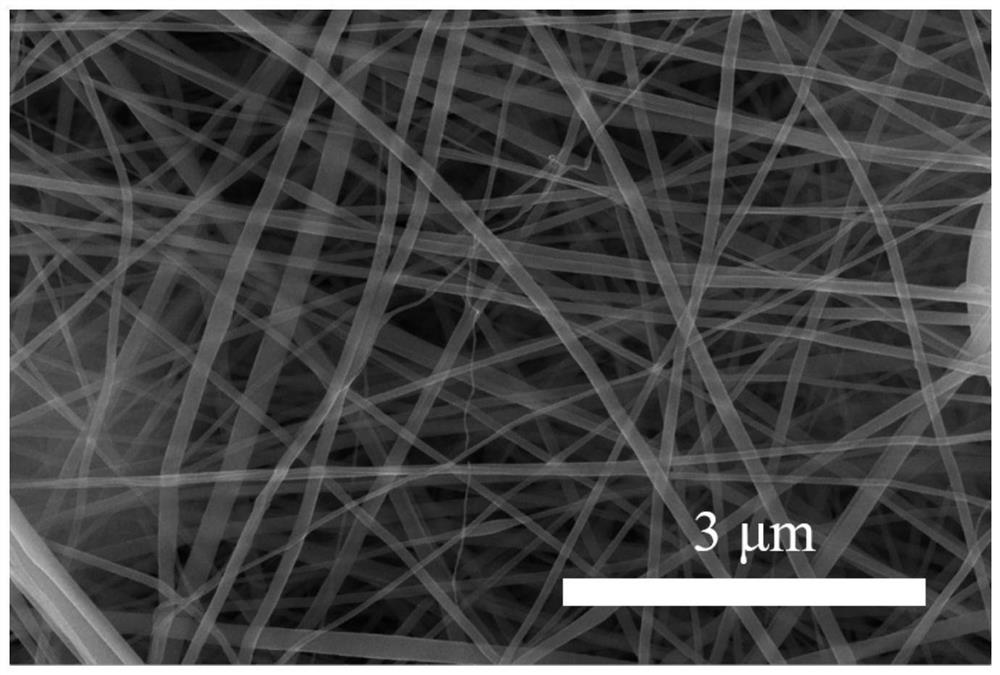

[0036] Step 1, prepare PVDF nanofiber base film

[0037] Dissolve 6g of PVDF in 44g of N,N-dimethylformamide, heat and stir, and obtain a uniform casting solution after vacuum degassing. The casting solution is injected into a syringe, and a No. 25 needle is installed on the syringe. The casting solution is injected into the booster of the electrospinning equipment, the propulsion speed of the booster is adjusted to 0.08mm / min, the distance between the needle and the receiver is adjusted to 8cm, and it is covered on the receiver of the electrospinning equipment A layer of tinfoil, set the rotation speed of the receiver to 80r / min. Connect the positive high voltage of the high-voltage power supply to the needle of the...

Embodiment 2

[0051] The method for constructing a superhydrophobic PVDF nanofiber membrane based on interfacial self-aggregation proposed by the present invention is used to prepare a superhydrophobic PVDF nanofiber membrane, which specifically includes the following steps:

[0052] Step 1, prepare PVDF nanofiber base film

[0053] Dissolve 6g of PVDF in 44g of N,N-dimethylformamide, heat and stir, and obtain a uniform casting solution after vacuum degassing. The casting solution is injected into a syringe, and a No. 25 needle is installed on the syringe. The casting solution is injected into the booster of the electrospinning equipment, the propulsion speed of the booster is adjusted to 0.08mm / min, the distance between the needle and the receiver is adjusted to 8cm, and it is covered on the receiver of the electrospinning equipment A layer of tinfoil, set the rotation speed of the receiver to 80r / min. Connect the positive high voltage of the high-voltage power supply to the needle of the...

Embodiment 3

[0059] The method for constructing a superhydrophobic PVDF nanofiber membrane based on interfacial self-aggregation proposed by the present invention is used to prepare a superhydrophobic PVDF nanofiber membrane, which specifically includes the following steps:

[0060] Step 1, prepare PVDF nanofiber base film

[0061] Dissolve 6g of PVDF in 44g of N,N-dimethylformamide, heat and stir, and obtain a uniform casting solution after vacuum degassing. The casting solution is injected into a syringe, and a No. 25 needle is installed on the syringe. The casting solution is injected into the booster of the electrospinning equipment, the propulsion speed of the booster is adjusted to 0.08mm / min, the distance between the needle and the receiver is adjusted to 8cm, and it is covered on the receiver of the electrospinning equipment A layer of tinfoil, set the rotation speed of the receiver to 80r / min. Connect the positive high voltage of the high-voltage power supply to the needle of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com