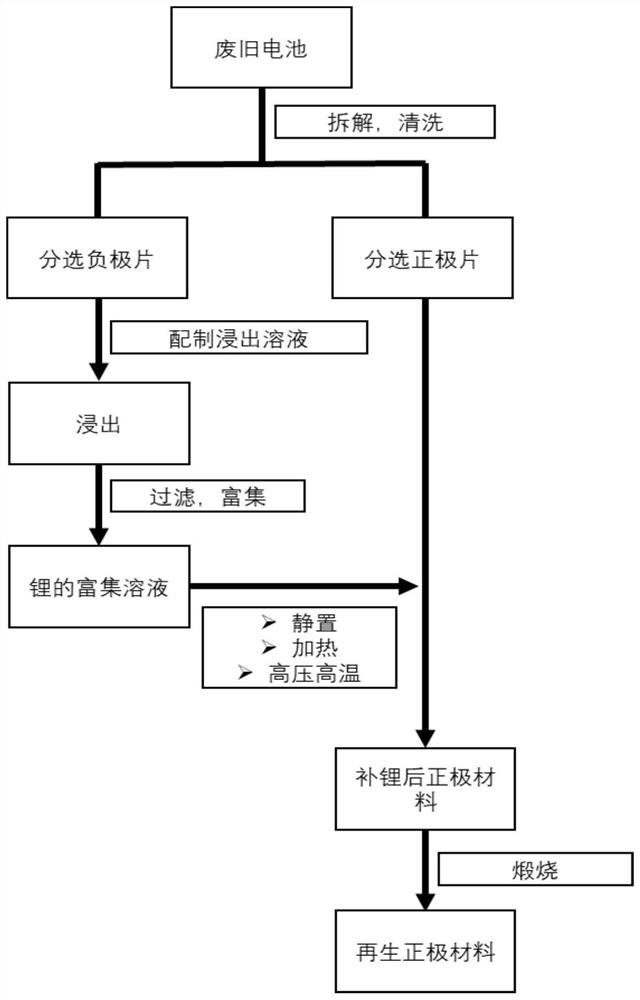

Closed-loop recycling method of lithium in lithium ion batteries

A lithium-ion battery, closed-loop technology, applied in battery recycling, recycling technology, battery electrodes, etc., can solve problems such as high energy consumption, non-compliance with energy conservation and emission reduction, reduce intermediate processing links, suitable for large-scale promotion, and enrich recycling effect of technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] (1) Disassemble the recycled waste batteries in a safe environment, and sort out the negative electrode pieces: in a drying room with a relative humidity of 5%, disassemble the waste nickel-cobalt manganate lithium batteries charged to 4.3V, and sort out Negative electrode sheet, to clean the residual lithium salt on the surface;

[0058] (2) Leach, separate and enrich the negative electrode sheet with the leaching solution to obtain a lithium enrichment solution: configure the leaching solution, add 20.2 g of pyrene and 100 ml of ethylene glycol dimethyl ether solvent into the flask, and stir until it becomes clear and transparent solution;

[0059] The cut negative electrode pieces were put into the leaching solution in batches, the leaching temperature was 60°C, and the solid-liquid mass ratio was 1:3. The leaching time was 2 hours. After the leaching is completed, the solution is suction filtered, separated, and the enriched solution of organolithium is obtained b...

Embodiment 2

[0064] (1) Disassemble the recycled waste batteries in a safe environment, and sort out the negative electrode pieces: Disassemble the waste nickel-cobalt manganate batteries charged to 4.3V in a drying room with a relative humidity of 5%, and sort out Negative electrode sheet, to clean the residual lithium salt on the surface;

[0065] (2) Leach, separate and enrich the negative electrode sheet with the leaching solution to obtain a lithium enrichment solution: configure the leaching solution, add 20.2 g of pyrene and 100 ml of ethylene glycol dimethyl ether solvent into the flask, and stir until it becomes clear and transparent solution;

[0066] The cut negative electrode sheets were put into the leaching solution in batches, the leaching temperature was 60°C, the mass ratio was 1:3, and the leaching time was 2 hours. After the leaching is completed, the solution is suction filtered, separated, and the enriched solution of organolithium is obtained by evaporating the solve...

Embodiment 3

[0071] (1) Disassemble the recycled waste batteries in a safe environment, and sort out the negative electrode pieces: Disassemble the waste nickel-cobalt manganate batteries charged to 4.3V in a drying room with a relative humidity of 5%, and sort out Negative electrode sheet, to clean the residual lithium salt on the surface;

[0072] (2) Leach, separate and enrich the negative electrode sheet with the leaching solution to obtain a lithium enrichment solution: configure the leaching solution, add 20.2 g of pyrene and 100 ml of ethylene glycol dimethyl ether solvent into the flask, and stir until it becomes clear and transparent solution; put the cut negative electrode pieces into the leaching solution in batches, the leaching temperature is 60°C, and the mass ratio is 1:3. The leaching time was 2 hours. After the leaching is completed, the solution is suction filtered, separated, and the enriched solution of organolithium is obtained by evaporating the solvent.

[0073] (3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com