Multi-clean-energy combined heat and steam supply system for explosive production and operation control method

A technology of clean energy and explosives, which is applied in the field of clean energy, can solve problems such as insufficient energy utilization, limited by external conditions, and not necessarily stable, and achieve intelligent energy management and control, scientific and reasonable equipment configuration, and high utilization efficiency. optimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

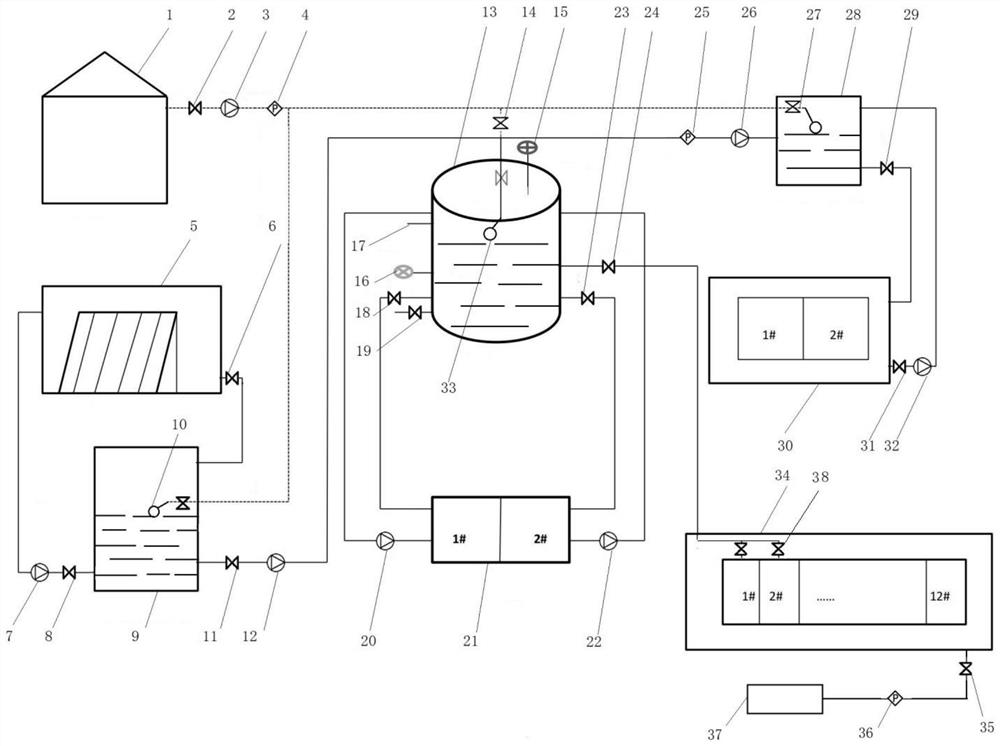

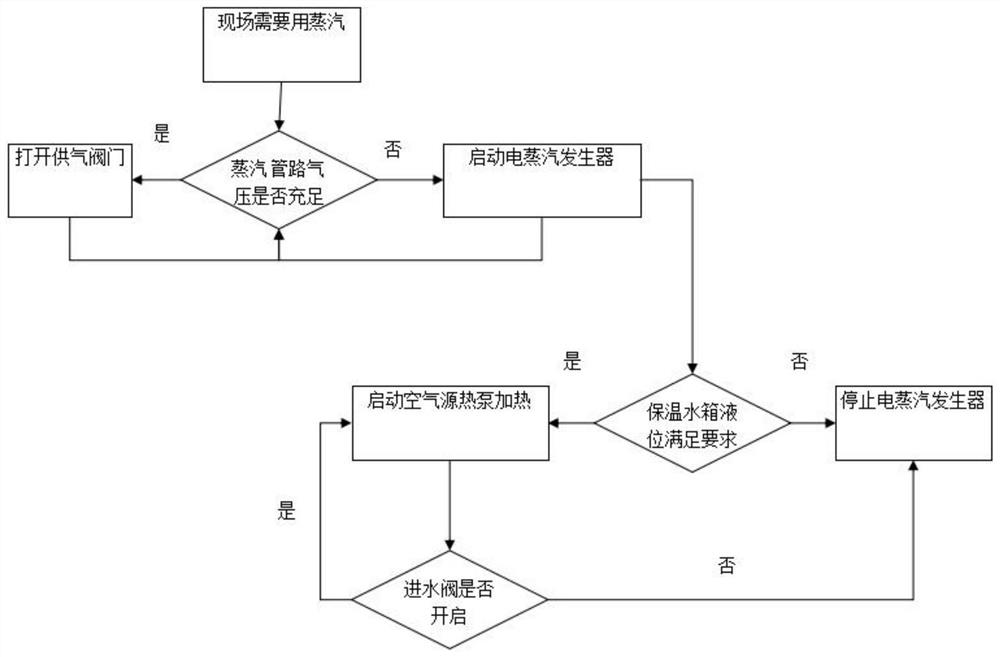

[0093] Such as figure 1 As shown, the technical solution provided by the present invention is: a combined heating and steam supply system for explosives production with a variety of clean energy sources, which provides domestic water, steam production and workshop warehouse insulation for the explosive detonator production line. The solar water heater of the water tank, the waste heat recovery device of the air compressor provided with the heat preservation water tank of the air compressor, the air source heat pump heating device provided with the water storage tank, and the electric steam generator also include a control system, and the control system is respectively connected with the Solar water heater, air compressor waste heat recovery device, air source heat pump heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com