Photoelastic method based on single-pixel imaging

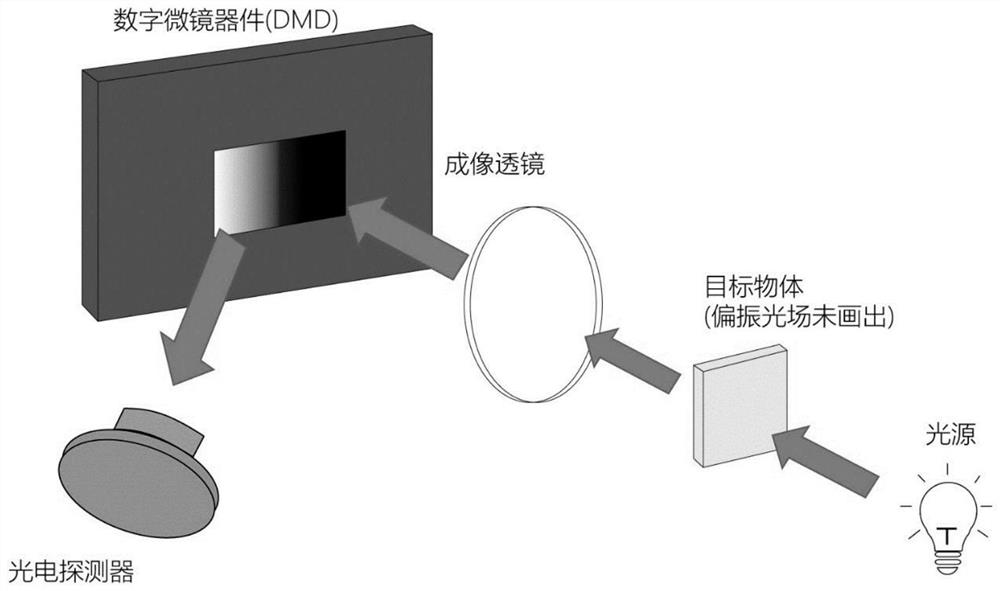

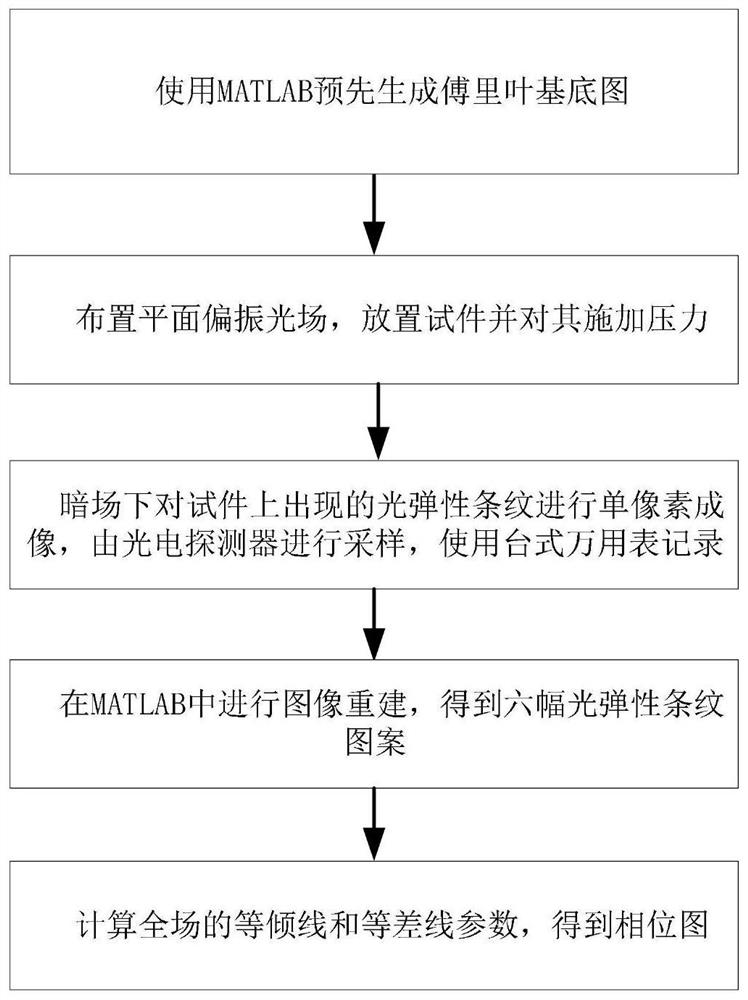

A single-pixel, photoelastic technology, applied in the field of optical imaging, can solve the problems of CCD or CMOS cameras that are difficult to manufacture, complex lens groups, and expensive, and achieve short response time, simplified optical design, and low manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

[0039] Before introducing the embodiments of the present invention, the technical idea of the present invention will be described in combination with the traditional photoelastic method and the Fourier single-pixel imaging method:

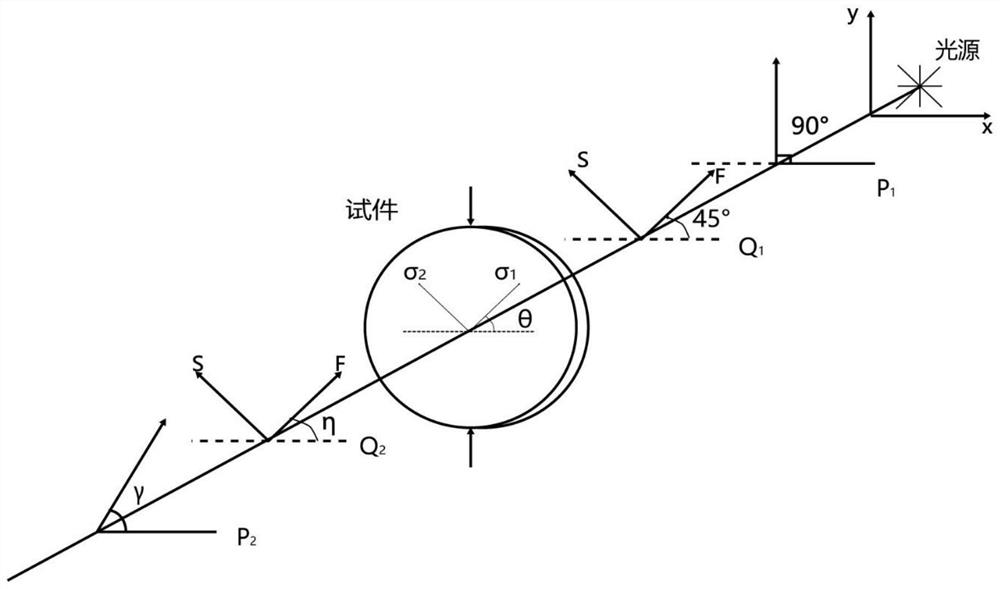

[0040] 1. Principle of photoelasticity method

[0041] The key to the stress analysis of the photoelastic method is to obtain the phase diagram of the isocline and contour line. The six-step phase shift method is one of the most commonly used methods in the image processing of the photoelastic method. The settings are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com