Full-automatic silicon wafer surface efficient scrubbing and cleaning device and operation method

A technology for cleaning the surface of silicon wafers, which is applied to cleaning methods and utensils, cleaning methods using liquid, heating devices, etc. Probability, the effect of speeding up the cooling rate and improving the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

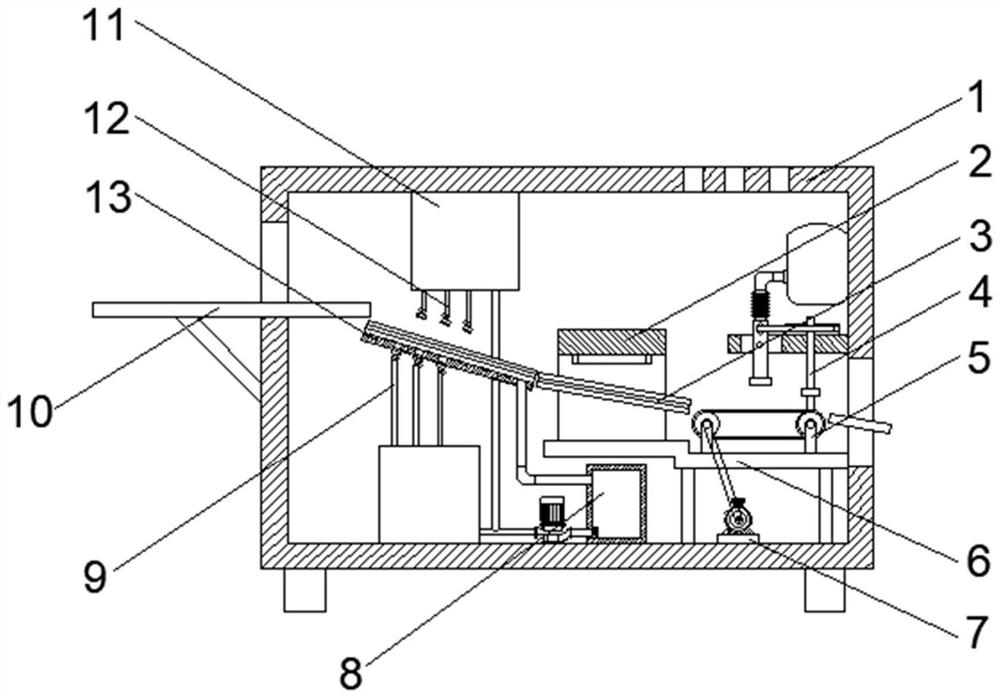

Embodiment 1

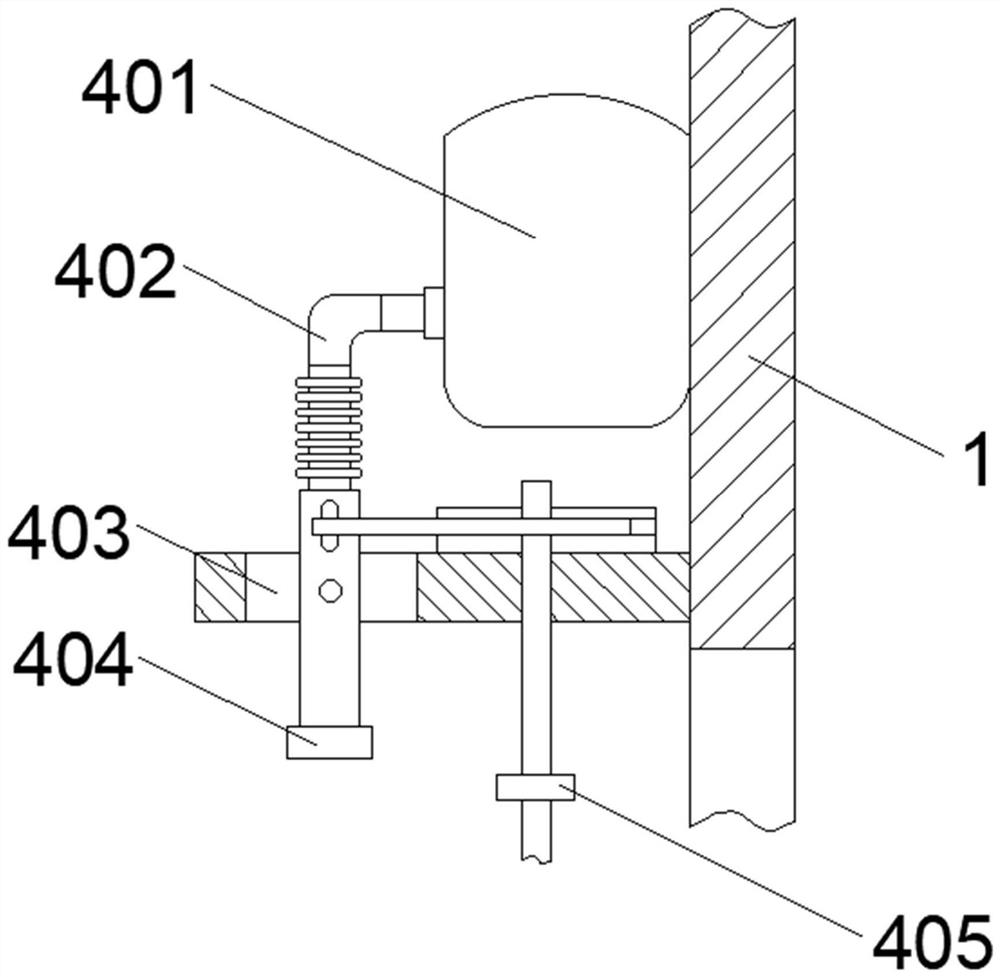

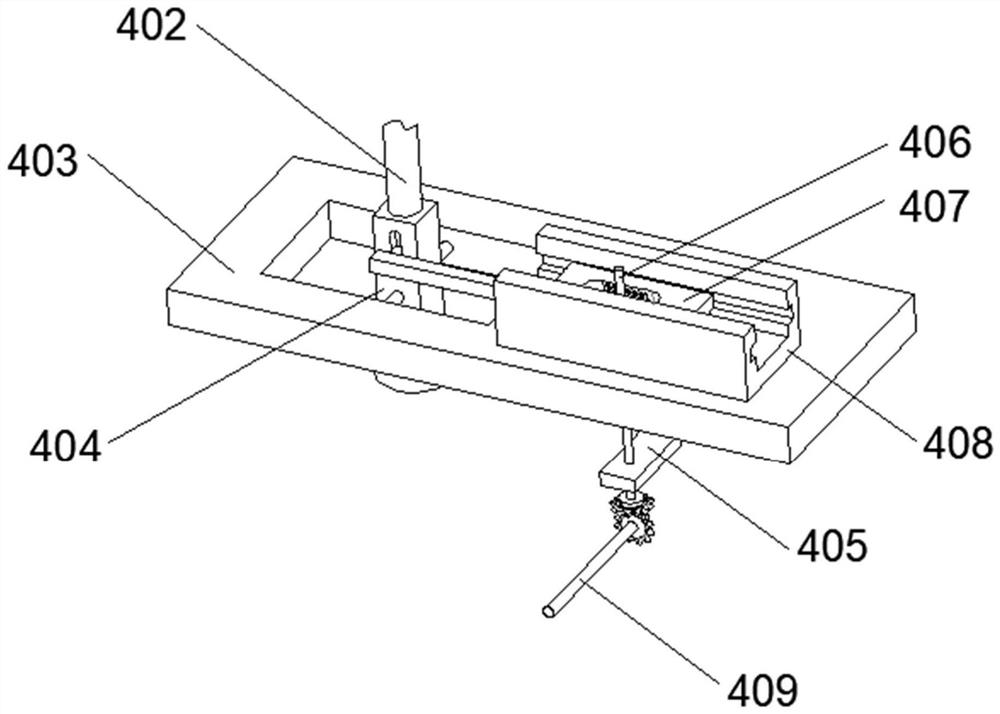

[0034] see figure 2 , image 3 with Figure 4As shown, the above-mentioned cooling mechanism 4 includes a refrigeration compressor 401 and a support plate 403 fixedly connected to the inner wall of the housing 1, a rotating hole is opened on the top surface of the support plate 403, and a hose 402 is connected to the output end of the refrigeration compressor 401. The bottom end of the pipe 402 is fixedly equipped with a nozzle 404, the top side of the nozzle 404 is provided with a first chute, the bottom of the nozzle 404 moves through the rotating hole, and the middle part of the nozzle 404 is connected to the inner wall of the rotating hole through a fixed pin. The fixing pin plays a position-limiting effect on the nozzle 404, which facilitates the rotation of the nozzle 404, so that the nozzle 404 can quickly and evenly cool down the dried silicon wafer. The top of the support plate 403 is fixedly equipped with a mounting block 408, and The top surface is provided with ...

Embodiment 2

[0037] see Figure 5 As shown, the above-mentioned recovery mechanism 8 includes a recovery box 805 fixedly connected to the inner wall of the housing 1. The top of the recovery box 805 is connected with a water inlet pipe 801, and the bottom of the recovery box 805 is connected with a drain pipe 803. The two output ends of the drain pipe 803 They communicate with the two water storage tanks 11 respectively, a water pump 802 is arranged in the middle of the drain pipe 803, and a filter screen 804 is provided at the junction of the drain pipe 803 and the recovery box 805, and dust and debris are filtered out through the filter screen 804, and then The filtered water is discharged through the water pump 802 for recycling.

[0038] see Image 6 As shown, the above-mentioned support mechanism 13 includes a slant plate 1301 fixedly connected to the inner wall of the housing 1, the top surface of the slant plate 1301 is provided with a third chute, and the inner walls on both sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com