Oil-water separation device and oil-water separation method

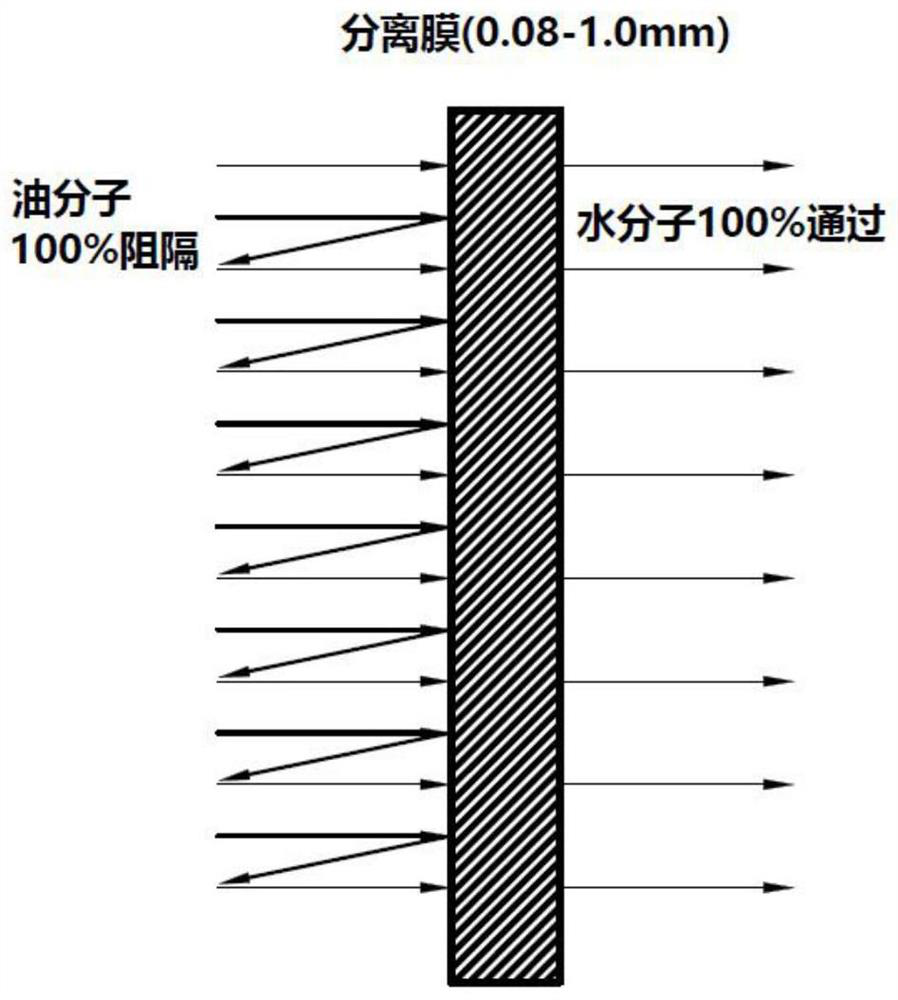

An oil-water separation device and technology for oil-water separation, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of low separation efficiency and incomplete separation, and achieve simple and easy operation, high oil-water separation efficiency, and complete separation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] In the present invention, the preparation method of the environment-friendly functional membrane material preferably includes the following steps:

[0040] mixing the preparation raw materials and performing plasticizing treatment to obtain a mixed material;

[0041] Extruding and granulating the mixed material to obtain pellets;

[0042] The pellets are extruded and blown to obtain an environment-friendly functional film material.

[0043] In the present invention, the preparation raw materials are preferably mixed and plasticized to obtain a mixed material. In the present invention, the mixing of the preparation raw materials is preferably carried out in a high-speed mixer; the stirring speed of the mixing is preferably 60-80 rpm. In the present invention, the temperature of the plasticizing treatment is preferably 40-60°C, more preferably 50°C; the time of the plasticizing treatment is preferably 60-120min, more preferably 90-100min. The plasticizing treatment of th...

Embodiment 1

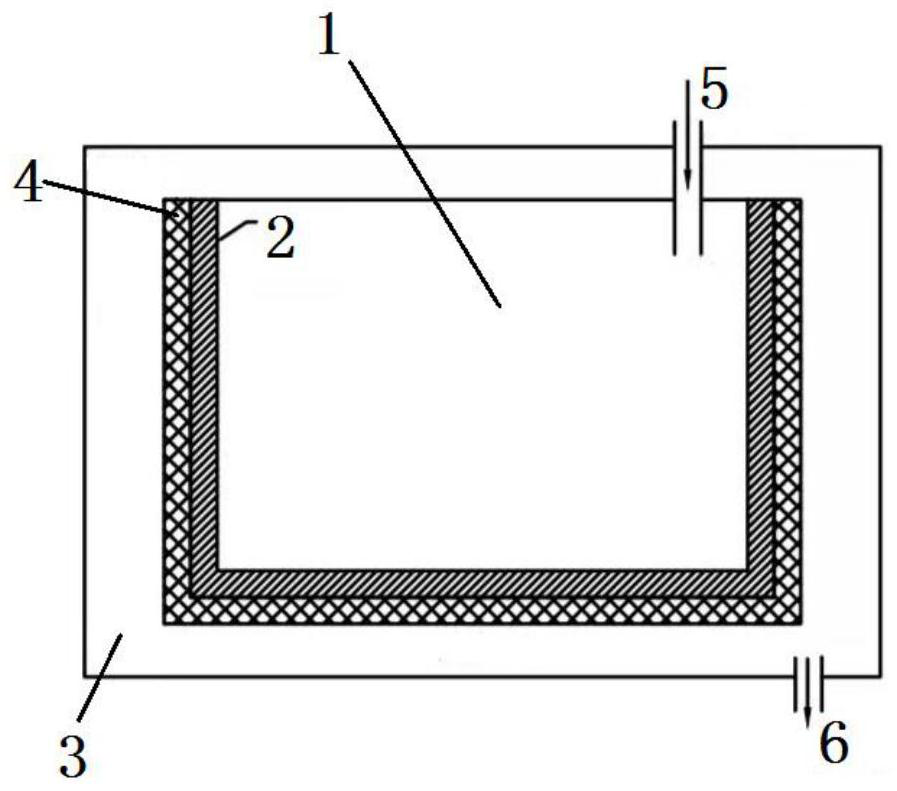

[0058] use figure 2 The shown oil-water separation device separates the oil-water mixture and is composed of a separation chamber 1, a clean water chamber 3 and a support net 4; the separation chamber 1 is nested inside the clean water chamber 3; the separation chamber 1 Both the bottom and side walls are environmentally friendly functional membrane materials 2, and the bottom and side walls of the separation chamber 1 are covered with support nets 3; the separation chamber 1 is a closed structure with an internal pressure of 0.1 MPa; the separation The top of the chamber is provided with a feeding port 5; the periphery of the separation chamber is a clean water chamber 3, which is a closed structure; the bottom of the clean water chamber 3 is provided with a water outlet 6.

[0059] The support net is a stainless steel wire mesh, the cross section of the mesh is circular, the diameter of the mesh is 0.8 mm, and the mesh aperture of the support net is 30 mm.

[0060] In part...

Embodiment 2

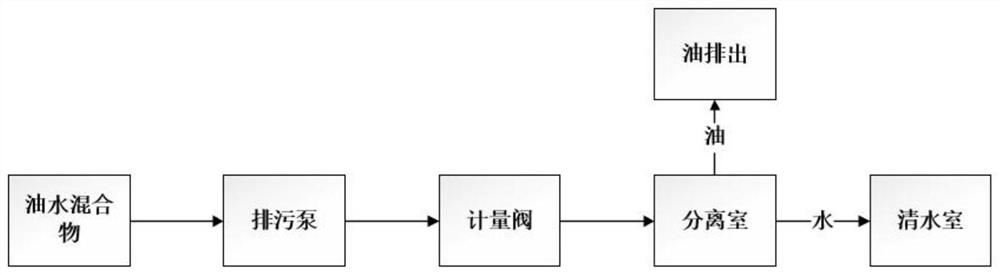

[0066] Adopt the oil-water separation device of embodiment 1, according to image 3 Process flow chart for oil-water separation.

[0067] Mix 100g of pure water and 100g of edible oil to obtain an oil-water mixture; transport the oil-water mixture to the separation chamber through a sewage pump, and a metering valve is arranged on the delivery pipeline to control the delivery amount of the oil-water mixture.

[0068] After standing at 25°C for 48 hours, the water in the separation chamber is discharged into the clean water chamber, and discharged after passing the water quality test; the oil phase blocked in the separation chamber is recycled and reused.

[0069] The test results prove that the oil-water mixture can be separated by 100% by using the oil-water separation device provided by the invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water vapor transmission rate | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Mesh aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com