Flexible anti-cracking covering anti-seepage material with steel slag as main material and construction technology

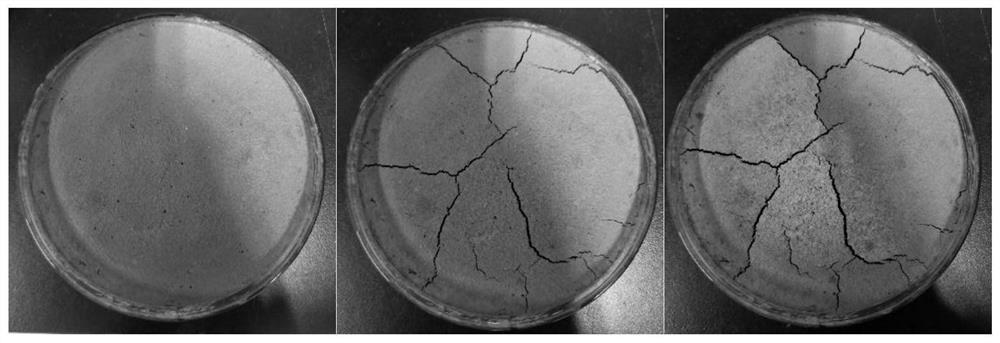

An anti-seepage material and construction technology technology, applied in the field of flexible anti-cracking covering anti-seepage material and construction technology with steel slag as the main material, can solve the problems of deterioration of anti-seepage performance, easy cracking of the covering layer anti-seepage material, etc. The effect of compaction, significant drop in performance, and improved durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The preparation and construction process of using the above-mentioned anti-seepage and anti-cracking material includes the following steps:

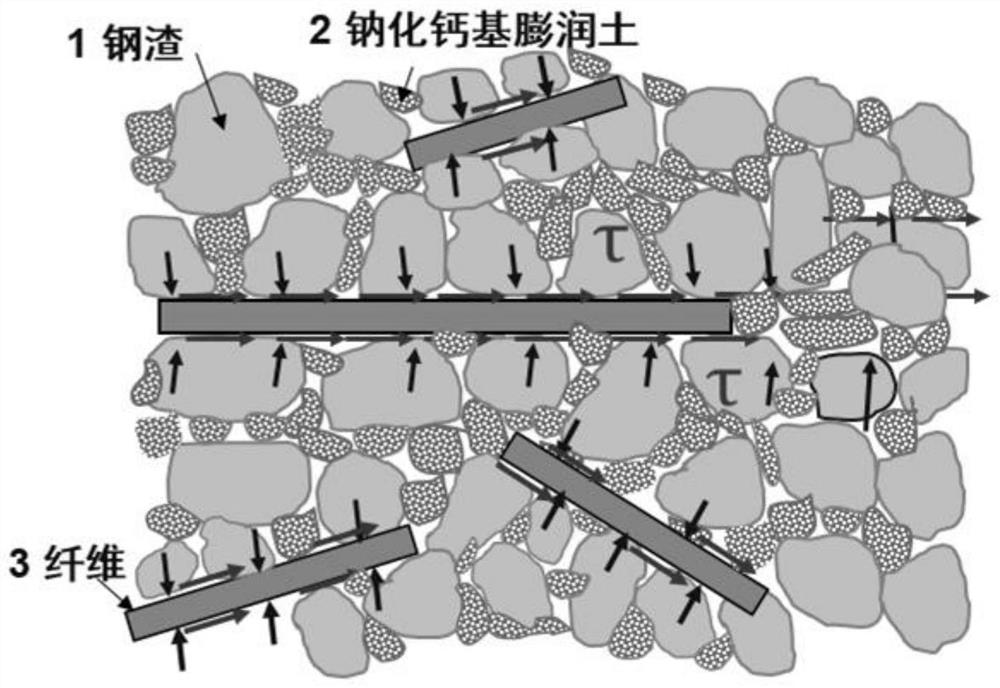

[0046] (1) Wash the natural steel slag and air-dry it, then sieve it according to four particle size ranges of 0.5-1mm, 0.25-0.5mm, 0.1-0.25mm and 0.075-0.1mm, and configure the steel slag 1 according to the optimal grading: The quality of the particle size between 0.5-1mm accounts for 40%, the mass of 0.25-0.5mm accounts for 30%, the particle size of 0.1-0.25mm accounts for 20%, and the particle size of 0.075-0.1mm 10%), and stir well. Then according to the demand, calculate and weigh the total amount of steel slag required (94.7% of the total mass) according to the compaction degree of 85%.

[0047] (2) Calculate according to the degree of compaction of 85% and weigh the required dry sodium calcium-based bentonite 2 total amount (accounting for 5% of the total mass), evenly add it to the steel slag, and carry out a process of n...

Embodiment 2

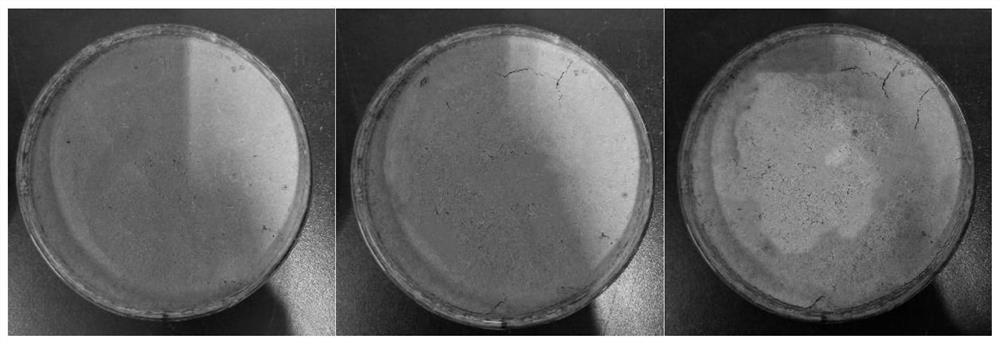

[0055] The anti-seepage material of Example 2 is slightly different from that of Example 1. The difference is that according to the mass ratio of steel slag, sodium calcium-based bentonite and fiber, it is specifically 92.1% of steel slag, 7.5% of sodium calcium-based bentonite, polypropylene Fiber 0.4%. In order to verify its anti-seepage performance and anti-cracking performance, the flexible wall penetration test and three dry-wet cycle tests were carried out respectively. The penetration test results are shown in Example No. 2 in Table 1, which meets the "Technical Specifications for Domestic Waste Landfill Treatment" (GB 50869-2013) Requirements for the permeability coefficient of anti-seepage materials, and no obvious cracks after three dry-wet cycles.

example 3

[0057] Example 3 anti-seepage material is slightly different from Example 1. The difference is that according to the mass ratio of steel slag, sodium calcium bentonite and fiber, it is specifically steel slag 89.5%, sodium calcium bentonite 10%, polypropylene fiber 0.5%. In order to verify its anti-seepage performance and anti-cracking performance, the flexible wall penetration test and 5 times of dry-wet cycle tests were carried out respectively. The penetration test results are shown in Table 1, Example No. 3, and the permeability coefficient of the anti-seepage material is not greater than 10. -7 cm / s, and no obvious cracks after wet and dry cycles.

[0058] Table 1 embodiment anti-seepage and anti-cracking effect

[0059]

[0060]As can be seen from the above table, the permeability coefficient of the flexible anti-cracking covering anti-seepage material based on steel slag obtained in Examples 1-3 all meets the requirements of "Technical Specifications for Domestic Wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| swell index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com