Water-soluble starch-based packaging buffer filler and preparation method thereof

A technology of water-soluble starch and buffer filler, applied in the field of water-soluble starch-based packaging buffer filler and its preparation, can solve the problems of low biodegradability of finished products, high cost of solid waste disposal, complicated operation steps, etc., and achieve Excellent cushioning performance, short time consumption, and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

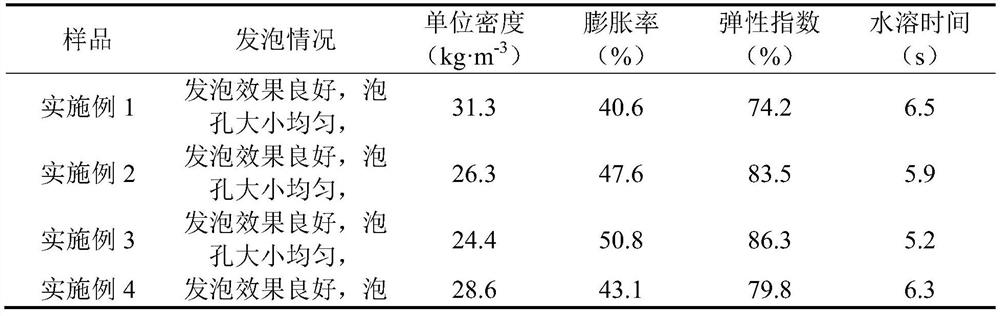

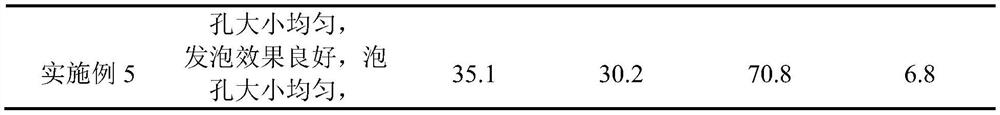

Examples

Embodiment 1

[0024] A raw material of a water-soluble starch-based packaging buffer filling: 60 parts of water-soluble cornstarch, 10 parts of deionized water, 10 parts of polyvinyl alcohol, 2 parts of glycerin and 0.1 part of zirconium salt.

[0025] Preparation steps: (1) Mix ionic water, polyvinyl alcohol, glycerin and zirconium salt at 40°C, slowly add water-soluble cornstarch into the mixture, and use an overhead stirrer in a constant temperature water bath at 60°C at 400rpm Thoroughly mixed for 0.5h to prepare the starch mixture, and put it into a sealed polyethylene plastic bag to balance for 24h.

[0026] (2) Melt and extrude the balanced hydroxypropyl starch mixture through a screw extruder in a single-screw extruder at a three-zone barrel temperature of 100°C-120°C-140°C and a screw speed of 10rpm to prepare Thermoplastic water-soluble starch.

[0027] (3) The thermoplastic water-soluble starch is ground, cut and granulated by means of a blade grinder with an inner diameter of 2...

Embodiment 2

[0030] A kind of raw material of water-soluble starch-based packaging buffer filling: 70 parts of water-soluble tapioca starch, 15 parts of deionized water, 5 parts of polyvinyl alcohol and 0.1 part of zirconium salt.

[0031] Preparation steps: (1) Mix ionic water, polyvinyl alcohol, glycerin and zirconium salt at 40°C, slowly add water-soluble tapioca starch to the mixture, and use an overhead stirrer in a constant temperature water bath at 65°C at 600rpm Thoroughly mixed for 1 h to prepare the starch mixture, and put it into a sealed polyethylene plastic bag to balance for 36 h.

[0032] (2) Melt and extrude the balanced hydroxypropyl starch mixture through a screw extruder in a single-screw extruder at a three-zone barrel temperature of 120°C-140°C-160°C and a screw speed of 20rpm to prepare Thermoplastic water-soluble starch.

[0033] (3) The thermoplastic water-soluble starch is ground, cut and granulated by means of a blade grinder with an inner diameter of 2mm, dried ...

Embodiment 3

[0036] The raw material of a water-soluble starch-based packaging buffer filling: 80 parts of potato water-soluble starch, 25 parts of deionized water, 20 parts of polyvinyl alcohol, 10 parts of glycerin and 0.3 parts of calcium hydroxide.

[0037] Preparation steps: (1) Mix ionic water, polyvinyl alcohol, glycerin and calcium hydroxide at 40°C, slowly add water-soluble potato starch into the mixture, and use an overhead stirrer in a constant temperature water bath at 70°C at 800rpm The starch mixture was prepared by mixing thoroughly for 1.5 hours, and put it into a sealed polyethylene plastic bag and equilibrated for 30 hours.

[0038] (2) Melt and extrude the balanced hydroxypropyl starch mixture through a screw extruder in a single-screw extruder at a three-zone barrel temperature of 140°C-140°C-140°C and a screw speed of 30rpm to prepare Thermoplastic water-soluble starch.

[0039] (3) The thermoplastic water-soluble starch is ground, cut and granulated by means of a bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com