Hydrogen production method based on solid oxide electrolyzed water

A technology of solid oxide and electrolysis of water, which is applied in the direction of electrolysis components and electrolysis processes, etc., can solve the problems of low hydrogen evolution efficiency, low intermolecular activity, and low efficiency of electrolysis of water, and achieve high efficiency, efficiency improvement, thermodynamics and chemistry The effect of improving dynamic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

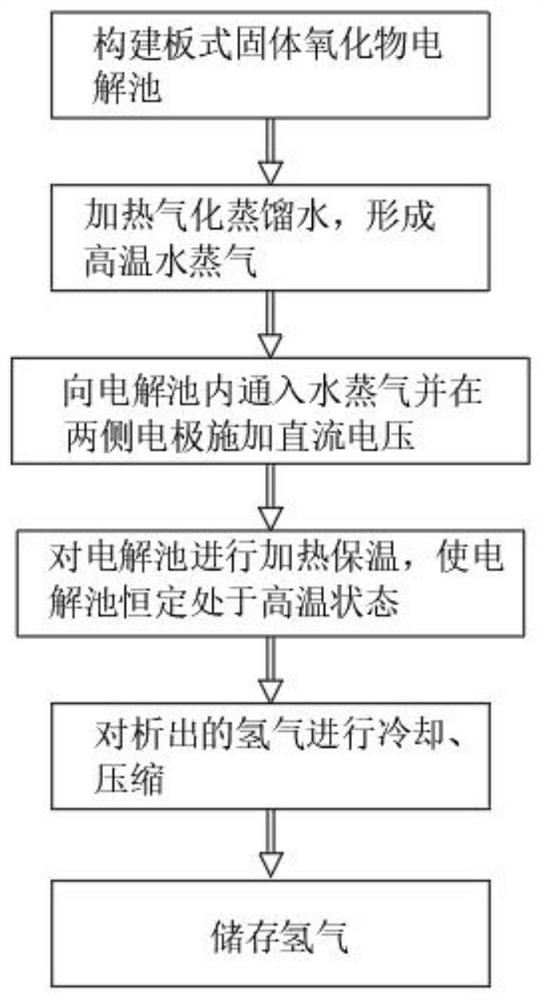

[0049] A method for producing hydrogen based on solid oxide electrolysis of water described in this embodiment comprises the following steps,

[0050] Step S1, constructing a flat-plate solid oxide electrolytic cell;

[0051] Specifically, the solid oxide electrolytic cell is a high-efficiency, low-pollution energy conversion device that can convert electrical energy and thermal energy into chemical energy. In principle, the solid oxide electrolytic cell, that is, SOEC, can be regarded as a solid oxide The reverse operation of the fuel cell (SOFC); and because the flat electrolytic cell has high energy density, and the manufacturing cost is relatively low, it is chosen to build a flat solid oxide electrolytic cell.

[0052] More specifically, the solid oxide electrolytic cell includes a dense electrolyte layer, a porous hydrogen electrode and a porous oxygen electrode. Among them, the dense electrolyte layer is used to separate air, oxygen and fuel gas, and to conduct oxygen ...

Embodiment 2

[0073] On the basis of Example 1, a method for producing hydrogen based on solid oxide electrolysis of water described in this example also includes the following steps,

[0074] Step S7, detecting the degree of polarization of the solid oxide electrolytic cell, and judging the loss of the electrode;

[0075] Step S8, performing adaptive supplementation based on the electrode loss amount obtained in step S7.

[0076] During use, the electrolytic reaction can be maintained continuously by monitoring the electrode loss in real time and replenishing it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com