Reinforcing structure of concrete ring piece splicing seam of fan power generation tower and construction method of reinforcing structure

A technology for wind power generation and structural reinforcement, which is applied in wind power generation, infrastructure engineering, installation/support of wind turbine configuration, etc. It can solve problems such as difficulty in ensuring that the glue layer is removed, construction quality cannot be guaranteed, and original structure damage, etc., to achieve Reliable connection and fixing effect, mature and reliable construction technology, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

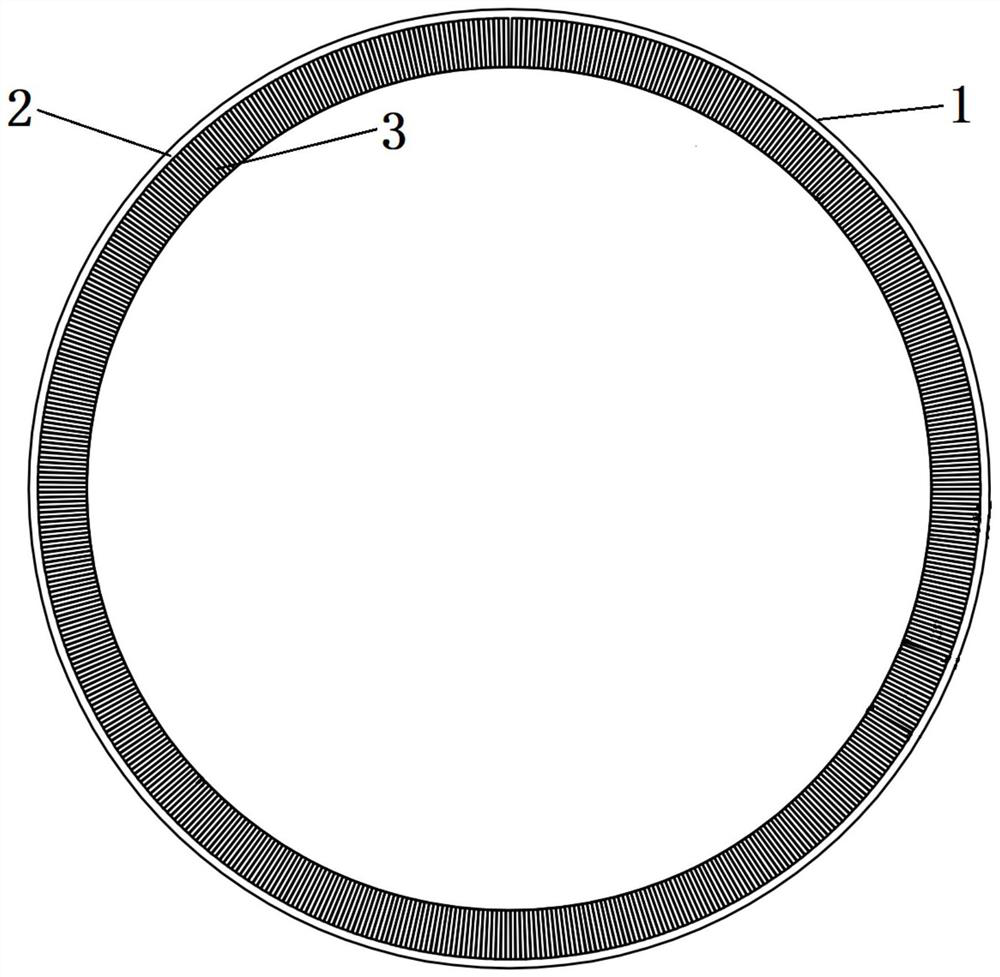

[0033] Embodiment 1: A reinforced structure for the splicing joints of concrete ring pieces of a wind power generation tower, including a tower tube formed by splicing more than one concrete ring piece with each other, and the concrete ring pieces are called upper concrete according to their relative positions on the tower tube The ring piece and the lower concrete ring piece, a protective layer of a certain thickness is provided on the outer wall of the concrete ring piece, and a plurality of ring-shaped steel bars for fixing are arranged in the protective layer, and splicing joints are formed between adjacent concrete ring pieces. Reinforcement implantation holes are respectively arranged in all joints, and several reinforcement implantation holes are evenly distributed on the same joint, and reinforcements are respectively implanted in all reinforcement insertion holes, and the reinforcement insertion holes The inner end is close to the inner side wall of the protective laye...

Embodiment 2

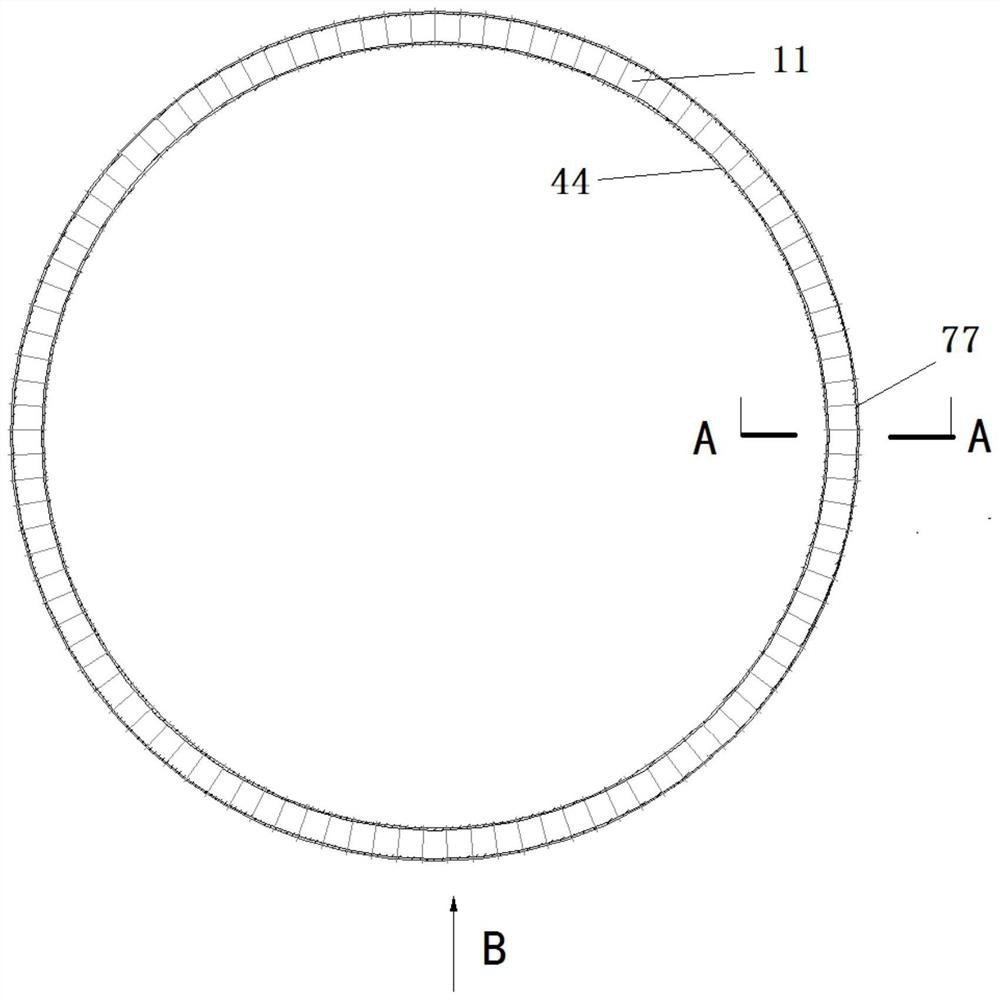

[0034] Embodiment 2: A reinforcement structure for the splicing seam of concrete ring pieces of a wind power generation tower, the concrete ring pieces are respectively spliced into an upper concrete ring piece 11 and a lower concrete ring piece 22, and the upper concrete ring piece 11 and the lower concrete ring piece 22 are spliced together Constructing the whole power tower concrete ring piece, at the splicing seam 33 of the upper concrete ring piece 11 and the lower concrete ring piece 22, its inner surface is lined with a reinforcement steel plate 44, and the thickness of the reinforcement steel plate 44 is 8-12mm. For example, the preferred reinforcing steel plate 44 has a thickness of 10mm. see figure 2 .

[0035] There is a steel bar implantation hole at the joint 33 of the concrete ring piece. The diameter of the steel bar implantation hole is larger than the width of the joint joint and less than twice the thickness of the concrete protective layer of the concr...

Embodiment 3

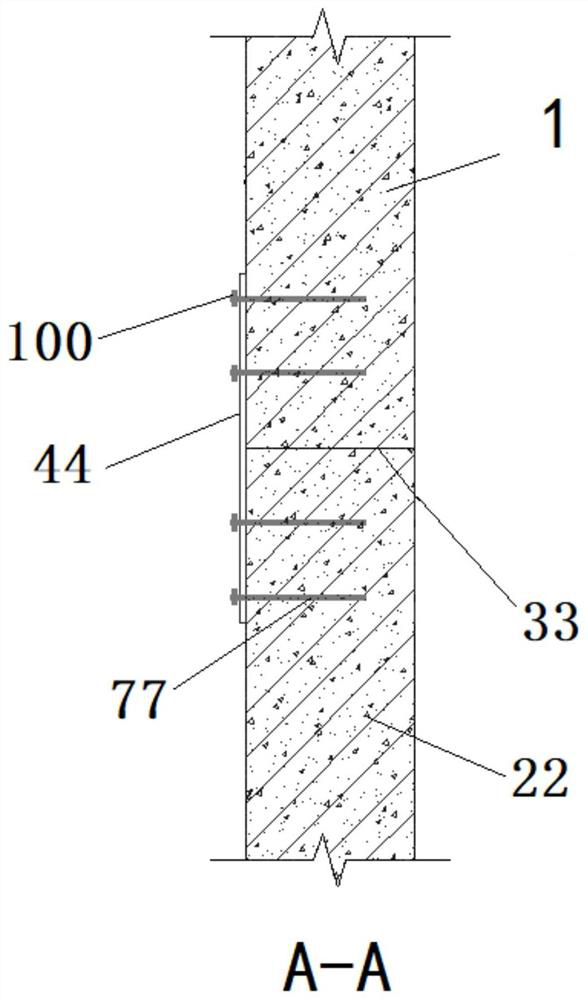

[0042] Embodiment 3: A reinforcement structure for splicing joints of concrete ring pieces of a wind turbine power tower, the steel rods are composed of hexagon head bolts 100 or studs. The mechanical property of the hexagonal head bolt 100 is 8.8, and the specification is M30×150mm; the installation pretightening force of the hexagonal head bolt 100 is 0.7-0.85σ s . see image 3 .

[0043] A kind of construction method of the reinforcing structure of the jointing seam of concrete ring piece of fan power generation tower of the present invention comprises the following steps:

[0044] (1) Remove the aging special adhesive, and remove the old special adhesive inside the seam of the concrete ring piece of the wind power tower;

[0045] (2) Process steel bar implantation holes and drill holes at the joints of the concrete rings of the wind power tower. The drilling requirements are: the diameter of the steel bar implantation holes is larger than the splicing between the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com